Optical sheet and surface light source apparatus

An optical sheet and one-sided technology, applied in the direction of electroluminescent light source, optics, light source, etc., can solve the problem of increased light loss, achieve the effect of small color change, reduce surface unevenness, and improve light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

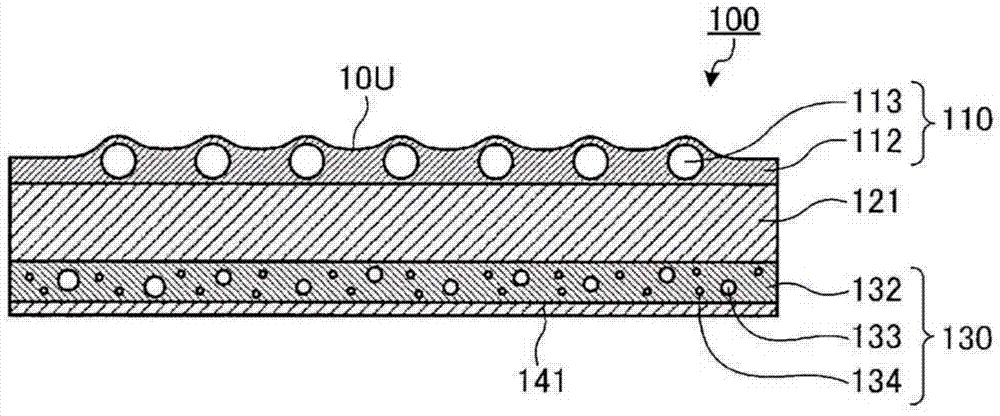

Embodiment 1

[0171] (1-1. Coating solution (1))

[0172] Add particles (silicone resin, refractive index 1.43) with a number average particle diameter of 4.5 μm as first diffusion particles to resin (UV curable resin mainly composed of urethane acrylate, refractive index after curing: 1.54) , stirring was performed to disperse the particles, and a coating solution (1) to be a material of the light diffusion layer was prepared. The content of the particles was set at 50% by weight of the total amount of the coating liquid (1).

[0173] (1-2. Coating solution (2))

[0174] Dissolve a resin (refractive index 1.48) mainly composed of acid-modified polyolefin polymer as a binder in a solvent mixed with methylcyclohexane and ethyl acetate at a ratio of 8:2 (weight ratio), Further, particles having a number average particle diameter of 0.6 μm (silicone resin, refractive index 1.43) as second diffusion particles and zirconia particles (number average particle diameter 20 nm, refractive index 1.9...

Embodiment 2

[0201] In the step (1-1), as the first diffusion particles, instead of particles having a number average particle diameter of 4.5 μm, particles having a number average particle diameter of 1.7 μm (silicone resin, refractive index 1.43) were used, and in addition, It carried out similarly to the process (1-1) - process (1-9) of Example 1, the optical sheet, the surface light source device, and other samples for research were produced and evaluated. The results are shown in Table 1.

[0202] In this example, the thickness of the light-diffusing layer obtained in step (1-5) was 15 μm, and a concavo-convex structure with Ra=0.3 μm was formed on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average particle size | aaaaa | aaaaa |

| Number average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com