An intelligent power equipment installation lifting device

A technology of power equipment and lifting devices, which is applied in the direction of lifting devices, lifting frames, etc., can solve the problems of inconvenient installation, increased work intensity, and difficulty in manual handling and unloading, so as to achieve convenient installation, reduce work intensity, and reduce labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

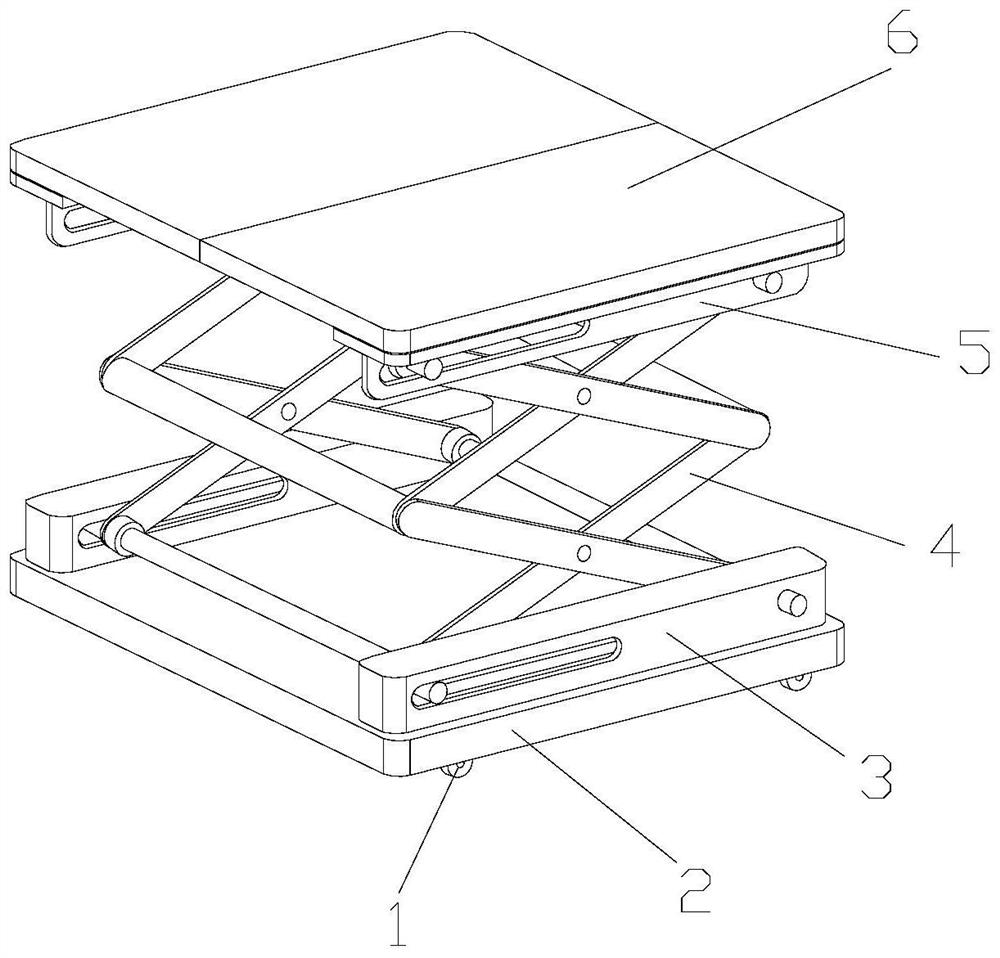

[0028] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

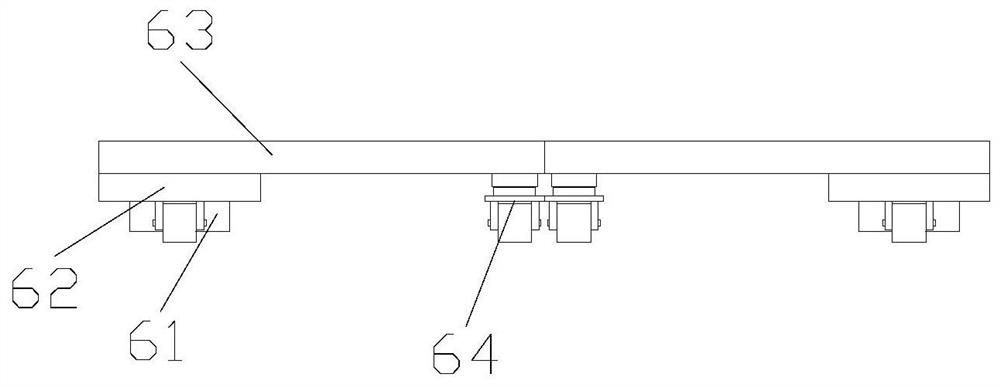

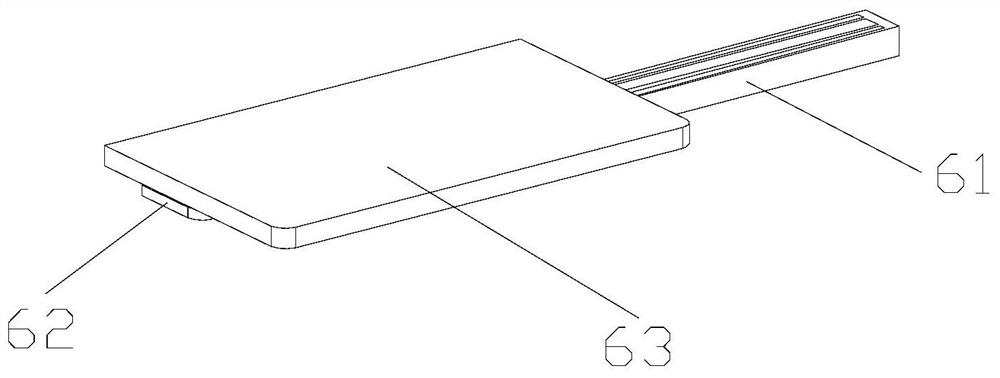

[0029] Its structure includes caster 1, bottom plate 2, driving box 3, scissors-type bracket 4, movable frame 5, lifting structure 6, said caster 1 is installed on the lower end of bottom plate 2 and adopts hinge connection, and said driving box 3 is fixedly installed on The upper end of the base plate 2, the scissor bracket 4 is embedded and installed between the drive boxes 3 and is movably connected, the movable frame 5 is hinged to the upper end of the scissor bracket 4, and the lifting structure 6 is fixedly installed on the movable frame 5 upper ends and are welded; the lifting structure 6 includes a longitudinal movable structure 61, a lateral movable structure 62, a lateral movable plate 63, and universal wheels 64, and the horizontal movable structure 62 is horizontally installed on the upper end of the longitudinal movable structure 61 and adopts...

Embodiment 2

[0035] Example 2: Please refer to Figure 1-Figure 3 , Figure 6-Figure 8 , the specific embodiments of the present invention are as follows:

[0036] Its structure includes caster 1, bottom plate 2, driving box 3, scissors-type bracket 4, movable frame 5, lifting structure 6, said caster 1 is installed on the lower end of bottom plate 2 and adopts hinge connection, and said driving box 3 is fixedly installed on The upper end of the base plate 2, the scissor bracket 4 is embedded and installed between the drive boxes 3 and is movably connected, the movable frame 5 is hinged to the upper end of the scissor bracket 4, and the lifting structure 6 is fixedly installed on the movable frame 5 upper ends and are welded; the lifting structure 6 includes a longitudinal movable structure 61, a lateral movable structure 62, a lateral movable plate 63, and universal wheels 64, and the horizontal movable structure 62 is horizontally installed on the upper end of the longitudinal movable s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com