Process method of spandex super-soft velvet

A process method, super soft velvet technology, applied in the field of spandex super soft velvet, can solve the problems of insufficient fluffy, uneven fluffy fabric, unsatisfactory bulkiness of fabric, etc., and achieve the effect of fluffy fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] A process method for a spandex super soft fleece disclosed in the present invention comprises the following steps:

[0047] S1: Use spandex filament as the base layer and spandex filament as the surface layer to make grey fabric;

[0048] S2: Arrange the blank on the setting machine for pre-setting;

[0049] S3: Use a brushing machine to brush the surface of the grey cloth;

[0050] S4: Iron the fabric made of S3 once on a single-roller ironing machine;

[0051] S5: Use a shearing machine to subtract long hairs on fabrics made from S4;

[0052] S6: Dye the cloth made of S5;

[0053] S7: drying the fabrics made in S6 in a dryer;

[0054] S8: The fabric made of S7 is set at low temperature on the setting machine;

[0055] S9: Iron the fabric made of S8 for a second time, steam the fabric, and use a wool suction machine to absorb the floating hair on the surface of the fabric;

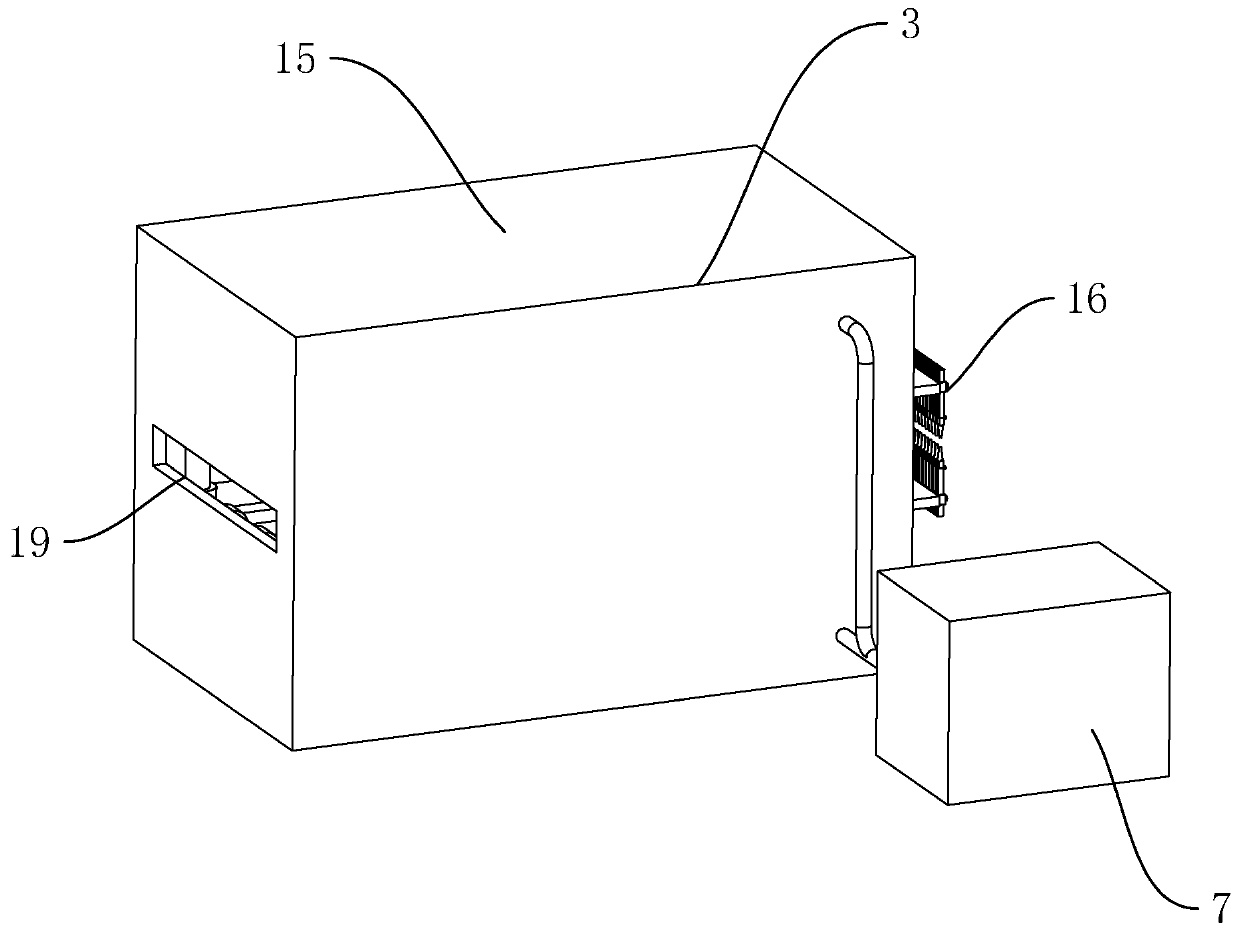

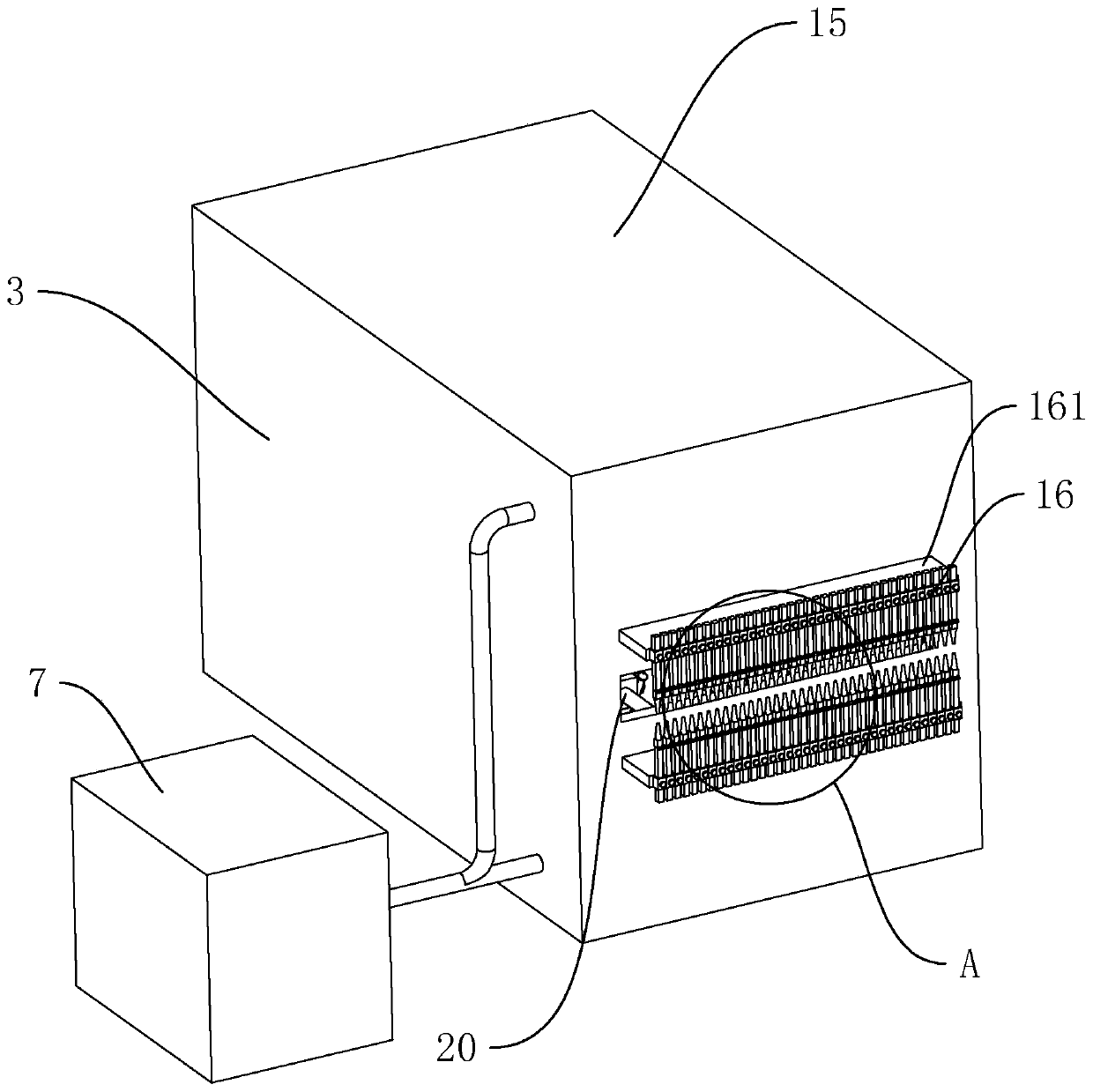

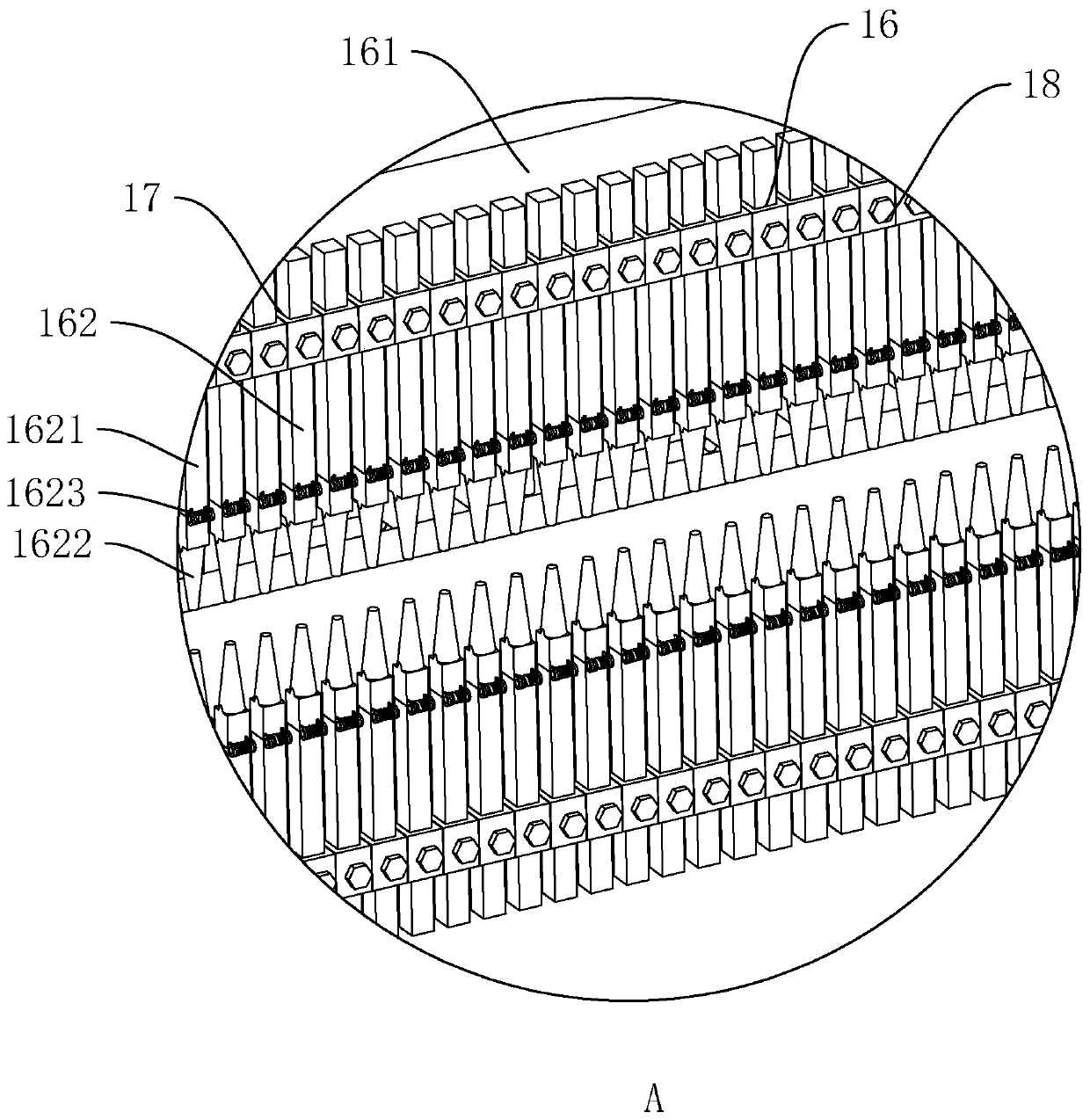

[0056] S10: The fabric after the steam treatment in S9 is horizontally transported into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com