Assembled intelligent floating slab rail unit and assembled connection construction method

A floating plate, assembled technology, applied in the field of rail transit, can solve the problems of limited construction space and transportation hoisting, inability to convert and use, poor driving safety, etc., to improve driving safety and vibration reduction effect, and reduce maintenance. The frequency and maintenance difficulty, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

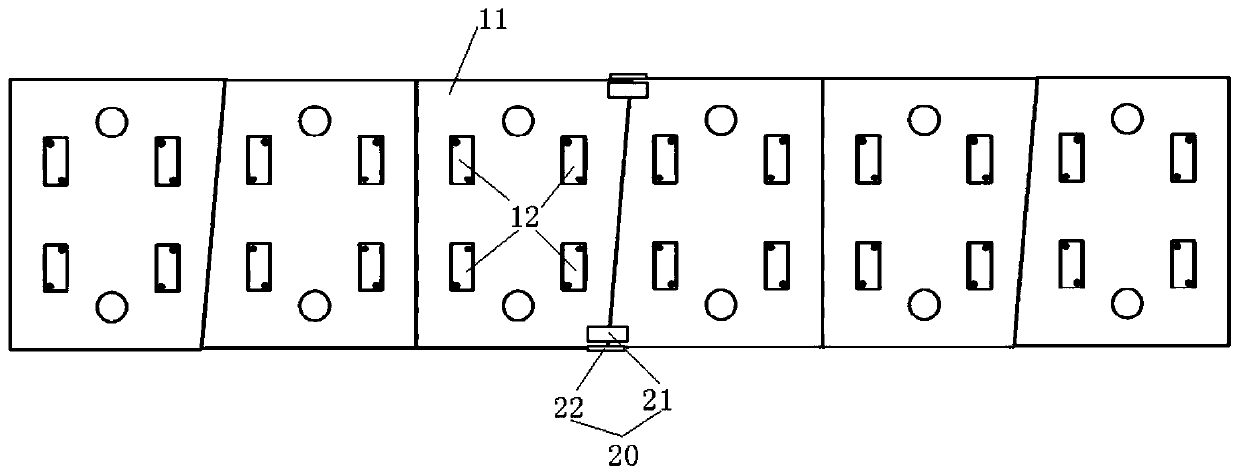

[0031] The construction method of the first embodiment of the connection structure of the present invention comprises the following steps:

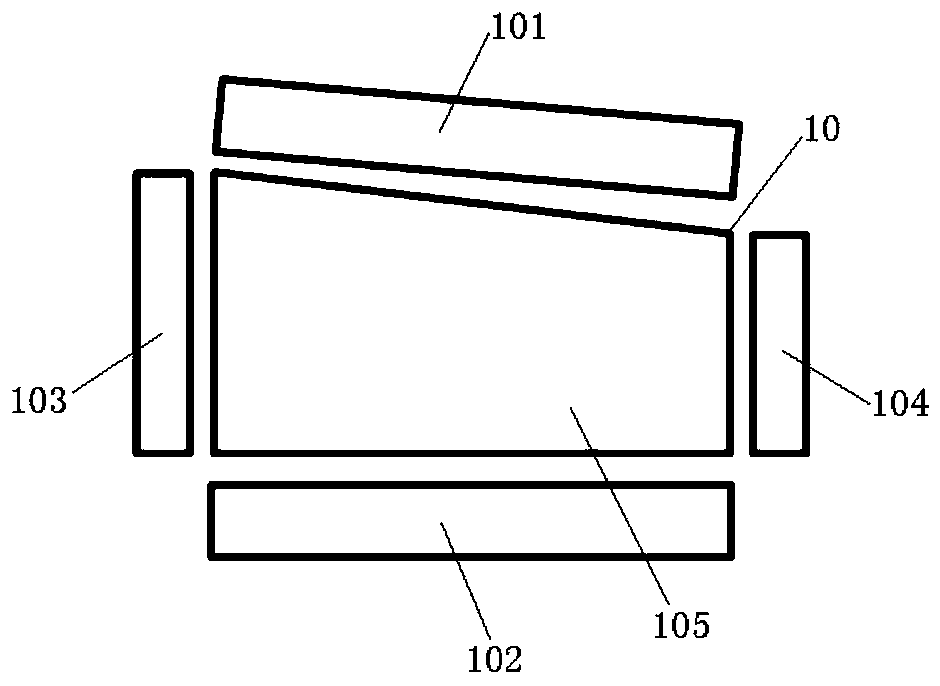

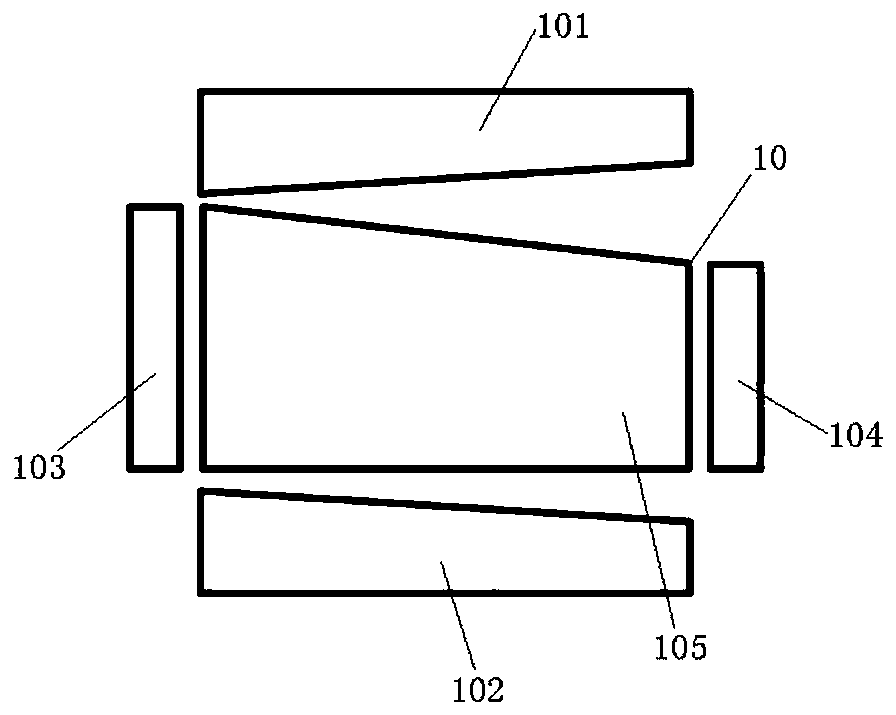

[0032] Mark the position of the floating plate unit block 10 by marking on the track foundation, hoist the pre-processed first floating plate unit block 10 to this position, and adjust the swing of the first floating plate unit block 10 place;

[0033] Lift the second floating plate unit block 10 to the above position, and adjust the placement position of the second floating plate unit block 10, so that the adjacent first connecting plate 211 and the second connecting plate 212 are opposed to each other, and the second connecting plate The bolt holes provided on the first connecting plate 211 are aligned with the bolt holes provided on the second connecting plate 212;

[0034] The first fastener 213 is threaded through the connecting end of the first connecting plate 211 and the connecting end of the second connecting plate 212 at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com