A grain sowing device with the function of pressing soil

A technology of seeding device and grain, applied in the directions of seeding, seeder parts, hole seeding machine, etc., can solve the problems such as insufficient pressure provided by the roller and troublesome use, so as to increase the pressure, ensure the soil compactness, and facilitate the follow-up. effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

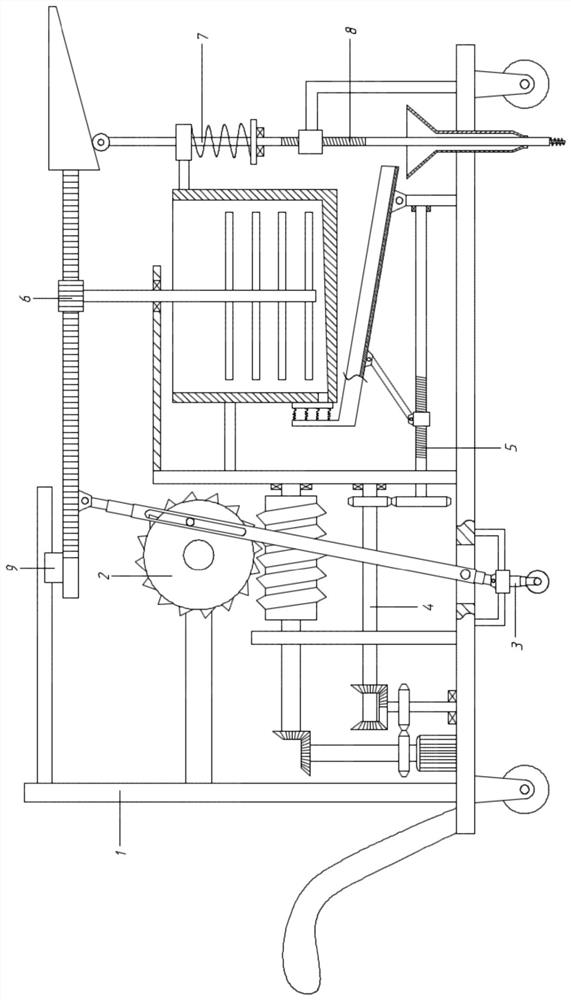

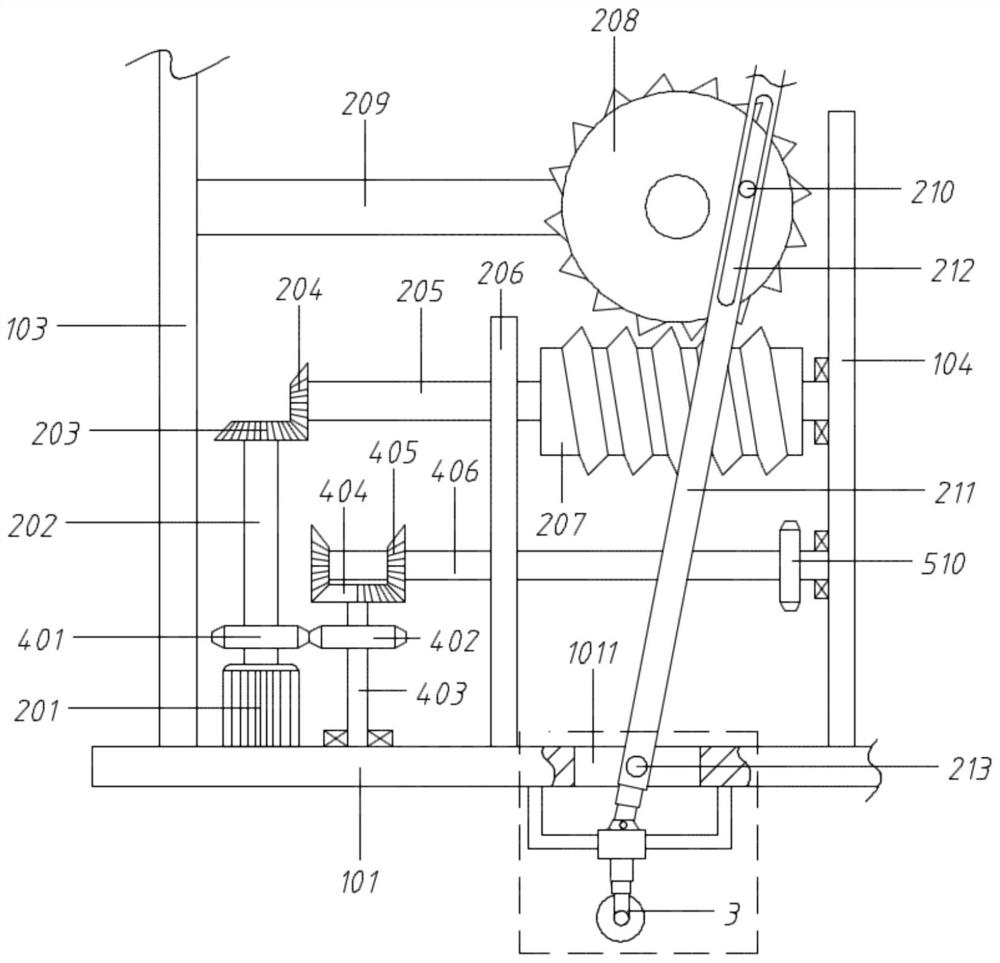

[0062] With reference to the accompanying drawings, a grain sowing device with the function of pressing the soil includes a car body 1, a power assembly 2, a soil pressing assembly 3, a transmission assembly 4, a reciprocating assembly 9, a planting assembly 5 and a hole-digging assembly 7;

[0063] Car body 1 comprises car plate 101, wheel 102, No. 1 vertical plate 103, No. 2 vertical plate 104, No. 1 pole 105, seed box 106 and pusher 107, and car plate 101 bottom is equipped with wheel 102, and car plate 101 A No. 1 vertical plate 103 and a No. 2 vertical plate 104 are fixedly connected at left and right intervals, and a push handle 107 is connected to the left end of the car plate 101; the power assembly 2 is arranged between the No. 1 vertical plate 103 and the No. 2 vertical plate 104, The bottom end of the power assembly 2 passes through the vehicle plate 101 and is provided with a compacting assembly 3; the seed box 106 is fixed on the right side of the second vertical p...

Embodiment 2

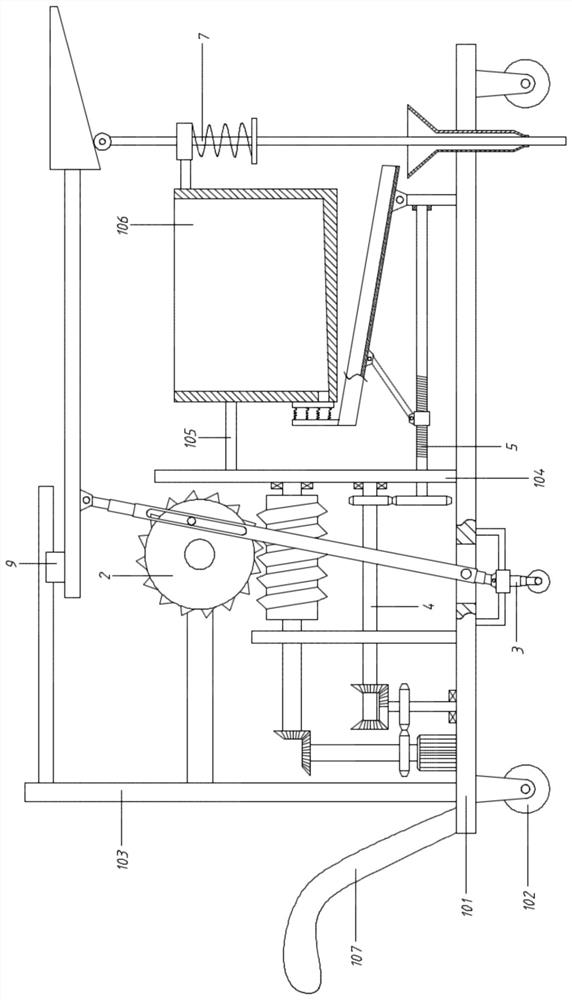

[0065] With reference to the accompanying drawings, a grain sowing device with the function of pressing the soil includes a car body 1, a power assembly 2, a soil pressing assembly 3, a transmission assembly 4, a reciprocating assembly 9, a planting assembly 5 and a hole-digging assembly 7;

[0066] Car body 1 comprises car plate 101, wheel 102, No. 1 vertical plate 103, No. 2 vertical plate 104, No. 1 pole 105, seed box 106 and pusher 107, and car plate 101 bottom is equipped with wheel 102, and car plate 101 A No. 1 vertical plate 103 and a No. 2 vertical plate 104 are fixedly connected at left and right intervals, and a push handle 107 is connected to the left end of the car plate 101; the power assembly 2 is arranged between the No. 1 vertical plate 103 and the No. 2 vertical plate 104, The bottom end of the power assembly 2 passes through the vehicle plate 101 and is provided with a compacting assembly 3; the seed box 106 is fixed on the right side of the second vertical p...

Embodiment 3

[0087] On the basis of embodiment 2,

[0088] It also includes a bulk material assembly 6; the bulk material assembly 6 includes a driven gear 605, a seventh rotating shaft 606, a second support plate 607 and a stirring rod 608;

[0089] The No. 2 support plate 607 is connected to the right side of the top of the No. 2 vertical plate 104, and is located above the seed box 106; the No. 7 rotating shaft 606 passes through the No. 2 support plate 607 vertically, and the bottom end extends into the seed box 106 and is evenly connected Stirring rod 608 is arranged, and driven gear 605 is equipped with on the top;

[0090] Specifically, when the long rod 903 moves left and right, the driven gear 605 drives the seventh rotating shaft 606 to rotate with the stirring rod 608, thereby stirring and breaking up the grain seeds in the seed box 106, which is beneficial to planting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com