Catalyst using graphene as carrier, preparation method of catalyst, method for degrading wastewater and application of catalyst

A graphene and catalyst technology, which is applied in the field of degrading wastewater, can solve the problems of high energy consumption, easy agglomeration, and high treatment costs, and achieve high stability, heat resistance, acid and alkali resistance, high oxidation performance, and high catalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] S11: Add 0.52 g (4 mmol) of cyanuric acid into the Erlenmeyer flask, add 20 mL of pure water, and then add an appropriate amount of PEI into the solution to dissolve the cyanuric acid.

[0042] S12: 0.32g (2.5mmol) of melamine was added to the Erlenmeyer flask, and 20mL of pure water was added to undergo ultrasonic treatment to form a suspension, and the suspension was added to the solution in a to form a white milky colloid.

[0043] S13: The white milky colloid was sonicated for 10 minutes, shaken at room temperature for 4 hours, filtered with a 0.22 μm filter membrane, placed in a glass dish, and kept overnight at 60° C. in a vacuum oven.

[0044] S1: Take out the melamine-cyanuric acid-polyimide in the glass dish and grind it into a fine powder, then take 1.25g and grind it evenly with 0.1g manganese chloride and 0.1g ferric chloride.

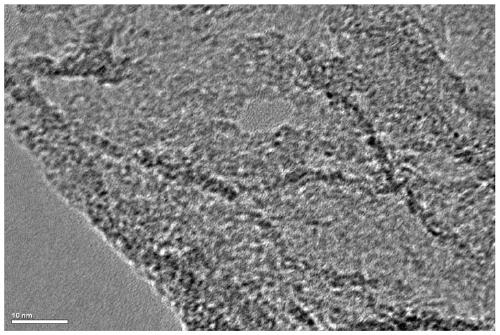

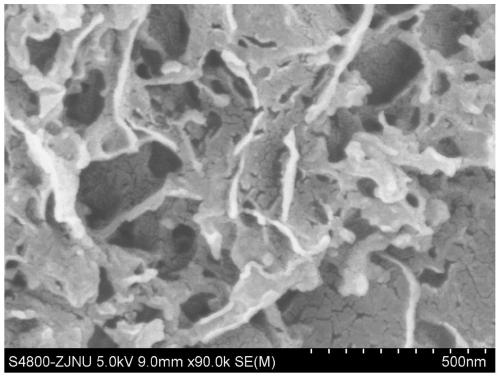

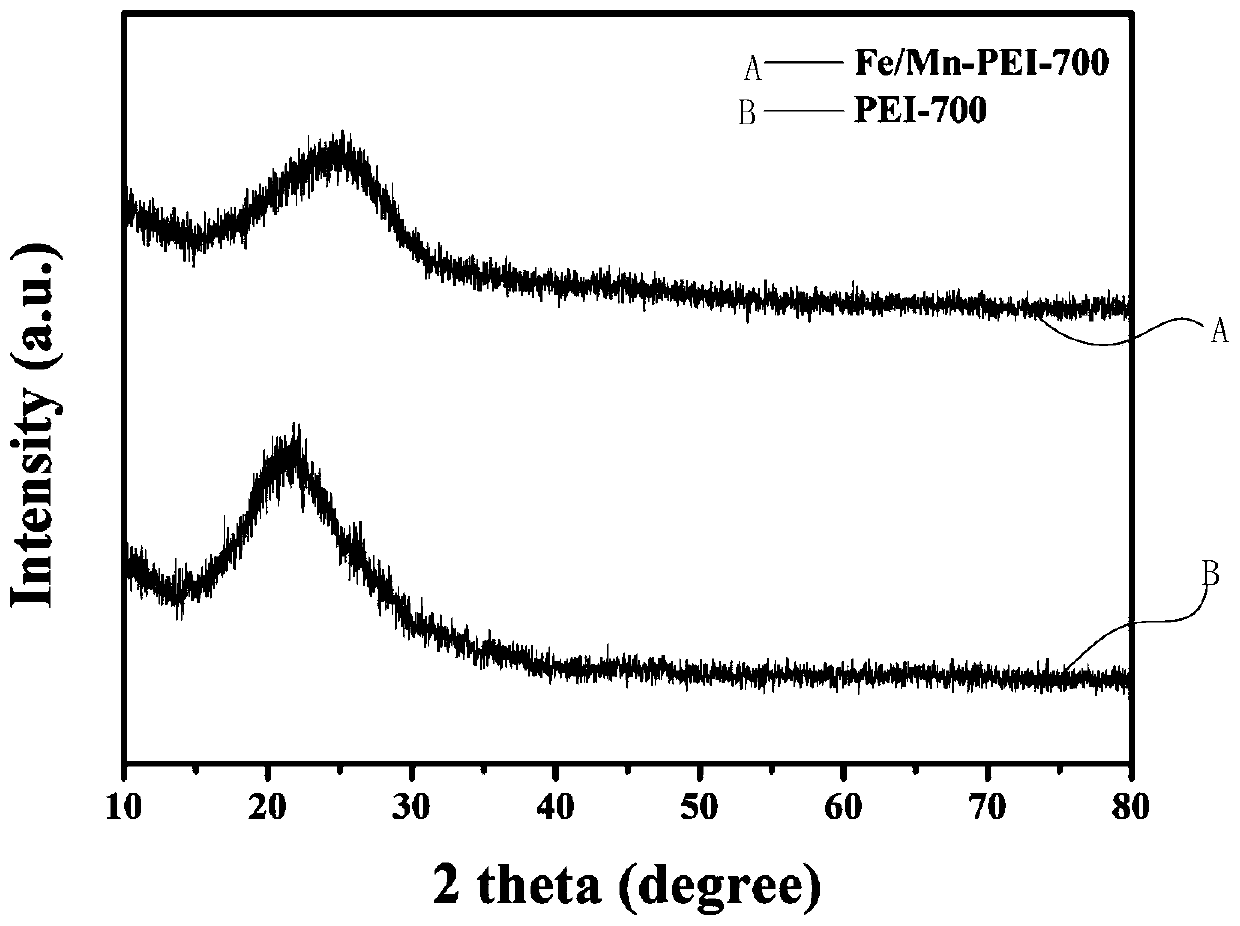

[0045] S2: Put the uniformly ground powder mixture into the tube furnace for calcination, and under the condition of blowing nitrog...

Embodiment 2

[0050] S11: Add 0.4 g (4 mmol) of cyanuric acid into the Erlenmeyer flask, add 60 mL of pure water, and then add an appropriate amount of PEI into the solution to dissolve the cyanuric acid.

[0051] S12: 0.2g (2.5mmol) of melamine was added to the Erlenmeyer flask, and 60mL of pure water was added to undergo ultrasonic treatment to form a suspension, and the suspension was added to the solution in a to form a white milky colloid.

[0052] S13: The white milky colloid was sonicated for 5 minutes, shaken at room temperature for 2 hours, filtered with a 0.22 μm filter membrane, placed in a glass dish, and kept overnight at 60° C. in a vacuum oven.

[0053] S1: Take out the melamine-cyanuric acid-polyimide in the glass dish and grind it into a fine powder, then take 1g and grind it evenly with 0.05g manganese chloride and 0.05g ferric chloride.

[0054] S2: Put the uniformly ground powder mixture into the tube furnace for calcination, and under the condition of blowing nitrogen, ...

Embodiment 3

[0057] S11: Add 0.6 g (4 mmol) of cyanuric acid into the Erlenmeyer flask, add 20 mL of pure water, and then add an appropriate amount of PEI into the solution to dissolve the cyanuric acid.

[0058] S12: 0.4g (2.5mmol) of melamine was added to the Erlenmeyer flask, and 20mL of pure water was added to undergo ultrasonic treatment to form a suspension, and the suspension was added to the solution in a to form a white milky colloid.

[0059] S13: The white milky colloid was sonicated for 20 minutes, shaken at room temperature for 6 hours, filtered with a 0.22 μm filter membrane, placed in a glass dish, and kept overnight at 60° C. in a vacuum oven.

[0060] S1: Take out the melamine-cyanuric acid-polyimide in the glass dish and grind it into a fine powder, then take 1.5g and grind it evenly with 0.2g of manganese chloride and 0.2g of ferric chloride.

[0061] S2: Put the uniformly ground powder mixture into the tube furnace for calcination, and under the condition of blowing nit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap