Welding machine for radiator and using method thereof

A welding machine, radiator technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problem of not meeting the needs and inconvenience of arc-shaped parts welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

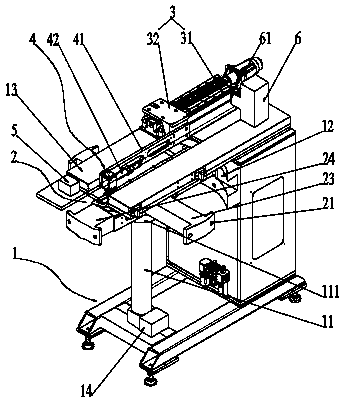

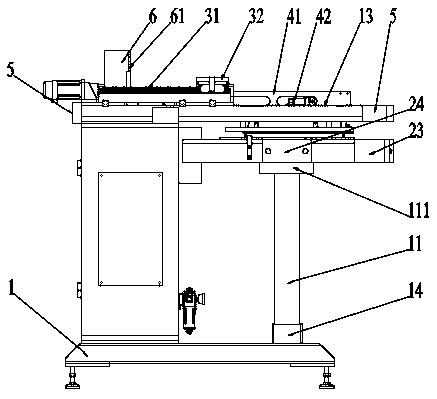

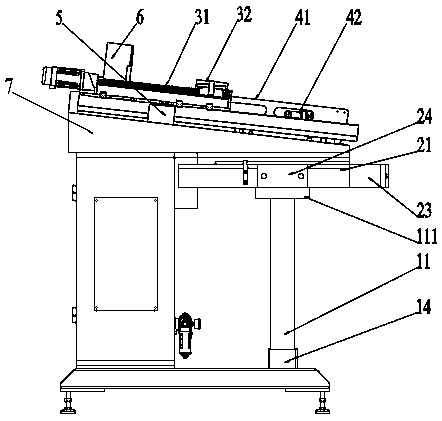

Image

Examples

Embodiment 1

[0055] For the welding of thin-walled parts, the welding torch assembly is selected as the welding assembly 4, and it is matched with the welding torch, and the automatic wire feeder and the pressure vessel are installed together. The position of the workbench 24 is such that the first workbench 23 or the second workbench 24 is parallel to the moving direction of the welding torch, and the workbench 2 is fixed by pins and positioning holes 21, and then the parts are directly fixed on the end surface of the workbench 2. After the material plate 131 is fixed, directly use the guide screw 31 and the moving block to drive the welding torch and the automatic wire feeding mechanism to do linear motion, so as to realize the welding of the parts.

Embodiment 2

[0057] For the welding of thin-walled parts, the welding torch assembly is selected as the welding component 4, and the welding torch is matched with the installation of the automatic wire feeder and the pressure vessel. The automatic wire feeder and welding wire can be purchased and installed directly. The seam is arc-shaped, and the workbench 2 can rotate through the gear box 14 at the lower end. After fixing the parts to be welded, adjust the position of the welding torch, slowly rotate the workbench 2, observe the welding position and adjust the welding torch position. The parts are fixed on the end surface of the workbench 2, and after being fixed by clamping blocks, the positions of the guide screw 31 and the moving slider 32 remain unchanged, and the rotating workbench 2 is used to realize arc welding.

Embodiment 3

[0059] For the welding of ordinary parts, the clamping welding tongs are used for the welding assembly 4, and the power line is connected with the tank chain. The welding rod is installed in the collecting box 6. The collecting box 6 is provided with a material guide groove 61, and the material guide groove 61 Only one row of welding rods can be placed and supported by the pressing spring, and one welding rod can be extended out of the discharge port at a time. This process can refer to the principle of a stapler. Before use, adjust the height of the clamping welding tongs so that The clip-type welding tongs can directly clamp the end of the welding rod. In order to realize automation, a pneumatic controller can be set on the upper end of the welding tongs to adjust the opening of the welding tongs in time. The length of the welding rod is relatively long. If necessary, the lower end of the support plate 13 needs to be equipped with a height adjustment plate 7 with a certain in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com