Adjustable variable-speed rotating nozzle and control method

A technology of rotating nozzles and nozzles, applied in spraying devices, spraying devices with movable outlets, etc., can solve the problems of lack of speed regulation structure, low test efficiency, high energy consumption, etc., to improve the efficiency of impact research experiments, selection and configuration Reasonable, simple and intelligent operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

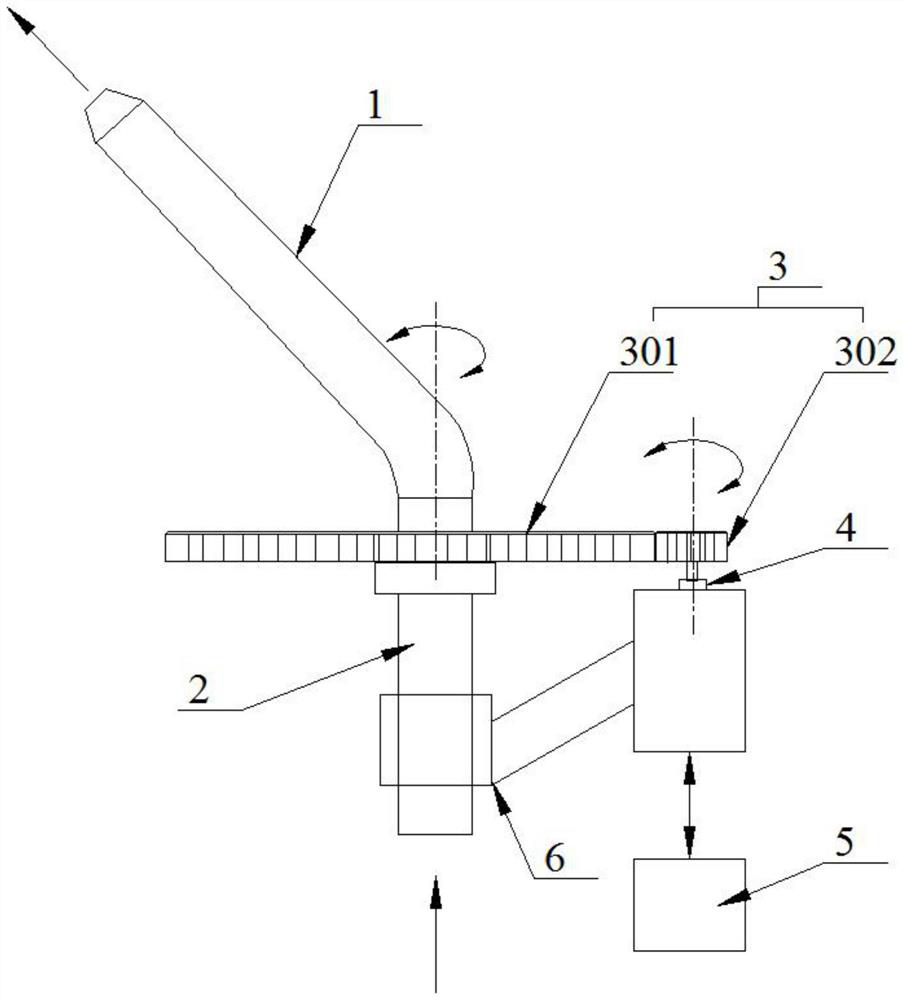

[0055] A preferred embodiment of the adjustable variable-speed rotating nozzle of the present invention, based on the adjustable variable-speed rotating nozzle described in Example 1, the method is as follows:

[0056] S1: Turn on the power of the motor control system 5, and set the initial rotation position, rotation angle, and rotation state of the nozzle body 1 through the button module 505, as the setting data of the logic processor 502, and output through the power drive module 503, Regulate the action of DC gear motor 4;

[0057] S2: The logic processor 502 controls the output of the power drive module 503 through PWM according to the program and the state signal of the DC gear motor 4 fed back by the Hall encoder, and regulates the action of the DC gear motor 4;

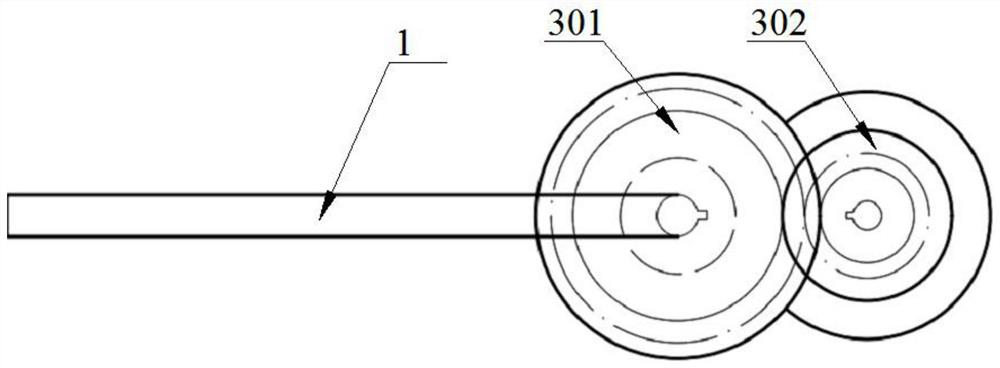

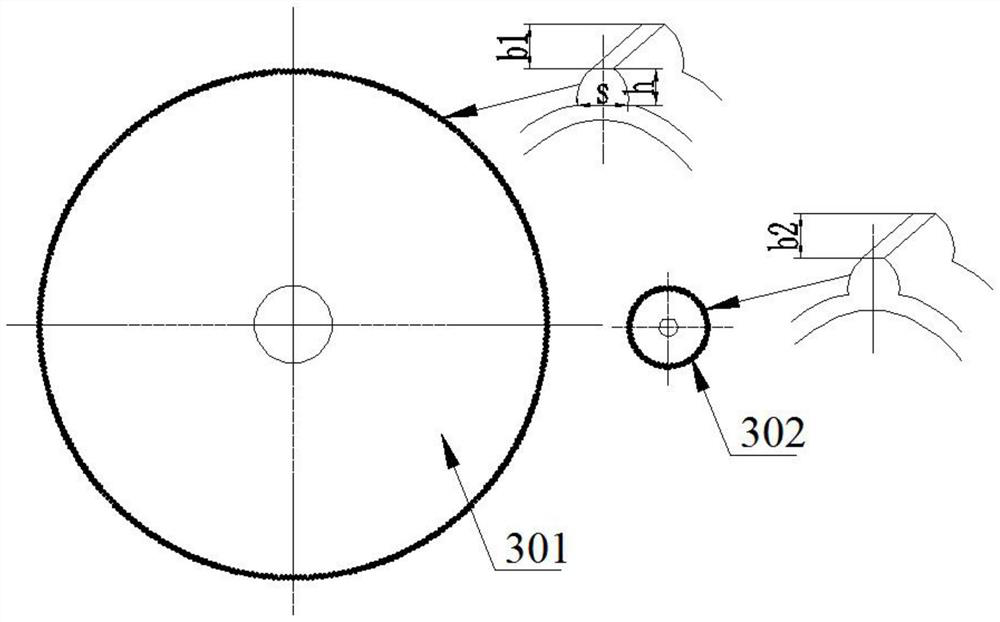

[0058] S3: The DC deceleration motor 4 drives the pinion 302 of the deceleration transmission mechanism 3 to rotate, and the main body 1 of the sprinkler is driven to rotate relative to the hollow shaft 2 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com