An automatic feeding device for a hinge installation mechanism

An installation mechanism and automatic feeding technology, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problem of installation progress caused by the device, and achieve the effect of improving work efficiency, reducing waste, and accurate feeding action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

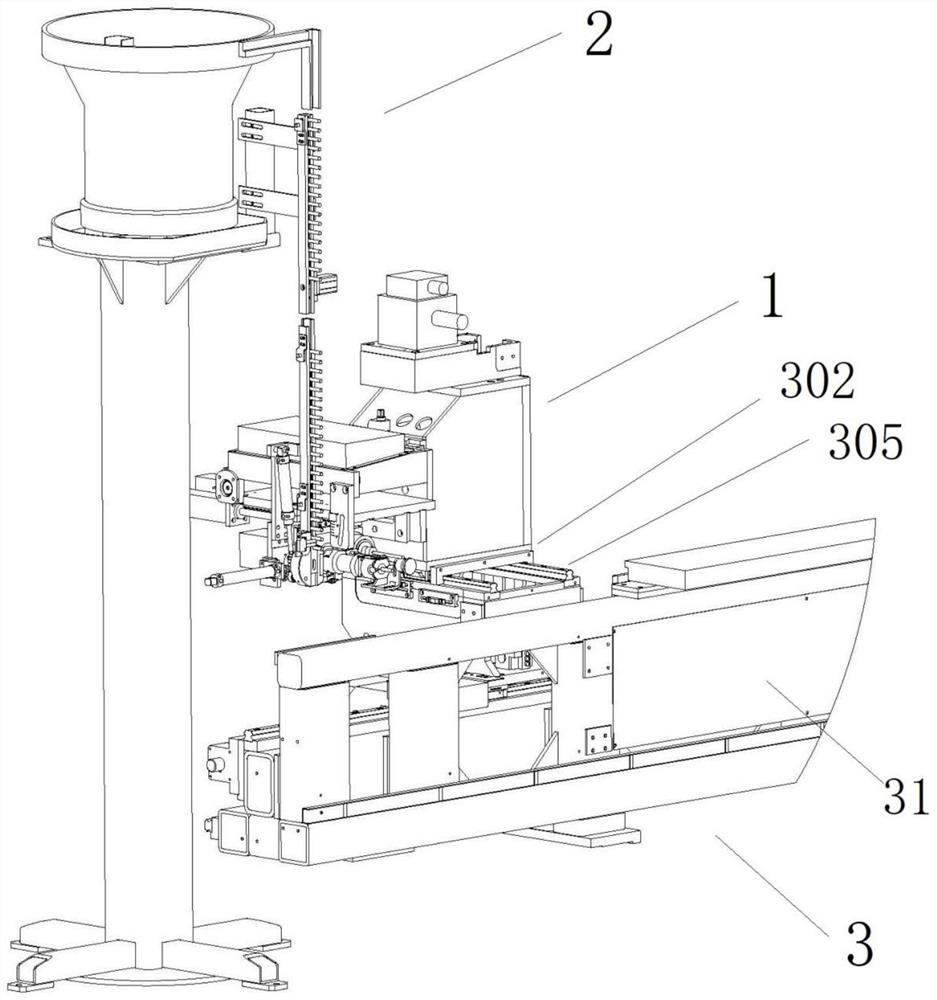

[0031] Such as figure 1 As shown, the automatic feeding mechanism of the hinge installation mechanism includes an installation mechanism 1 , a feeding mechanism 2 and a positioning mechanism 3 .

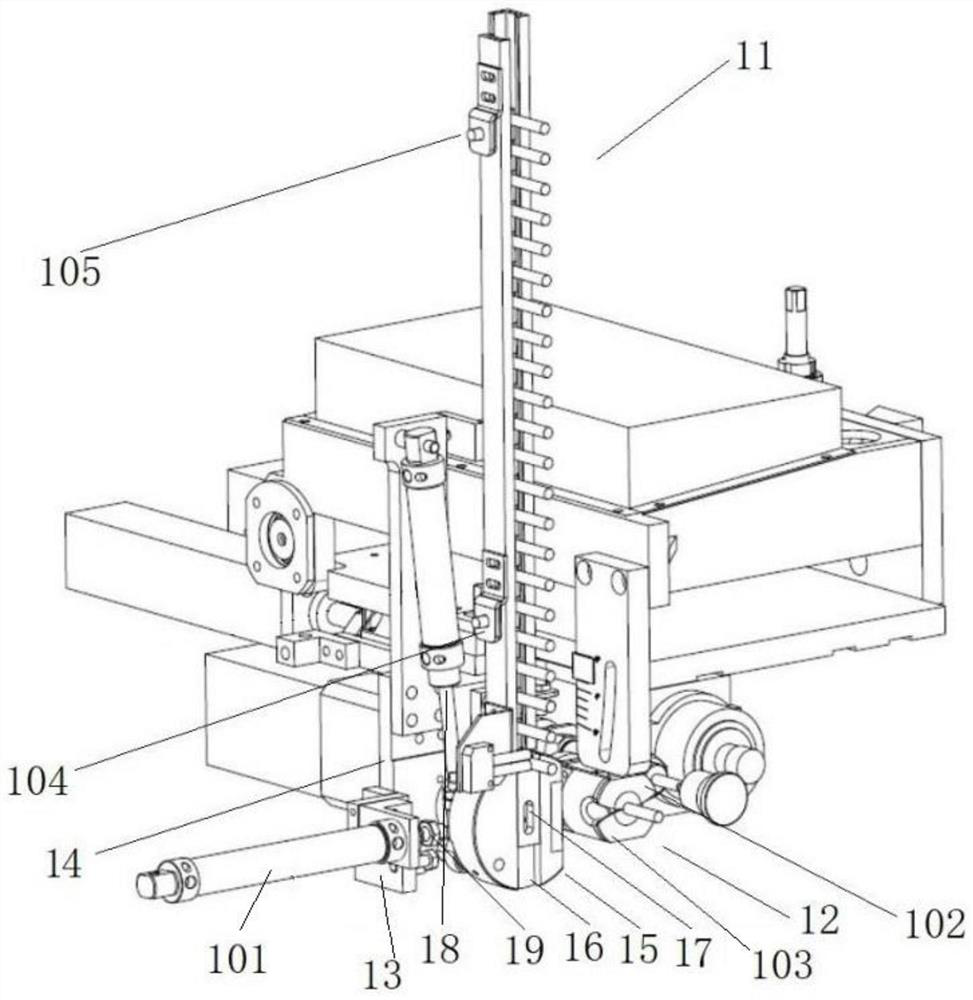

[0032] Such as figure 2 As shown, the installation mechanism 1 includes a first hinge library 11, a clamping part 12 and a telescopic device 13 for clamping and installing the hinge workpiece 4; the first hinge library 11 is arranged on one side of the installation mechanism 1 through a bracket 14 , the outlet of the first hinge storehouse 11 is provided with a rotating disk 15, the rotating disk 15 is provided with a feeding chute 16, and one end of the feeding chute 16 is provided with a positioning block 17, and the rotating disk 15 rotates until the feeding chute 16 is aligned with the outlet of the first hinge storehouse 11 At this time, the hinge workpiece 4 can be slid into the feeding trough 16 by the outlet of the first hinge storehouse 11, and is positioned by the positio...

Embodiment 2

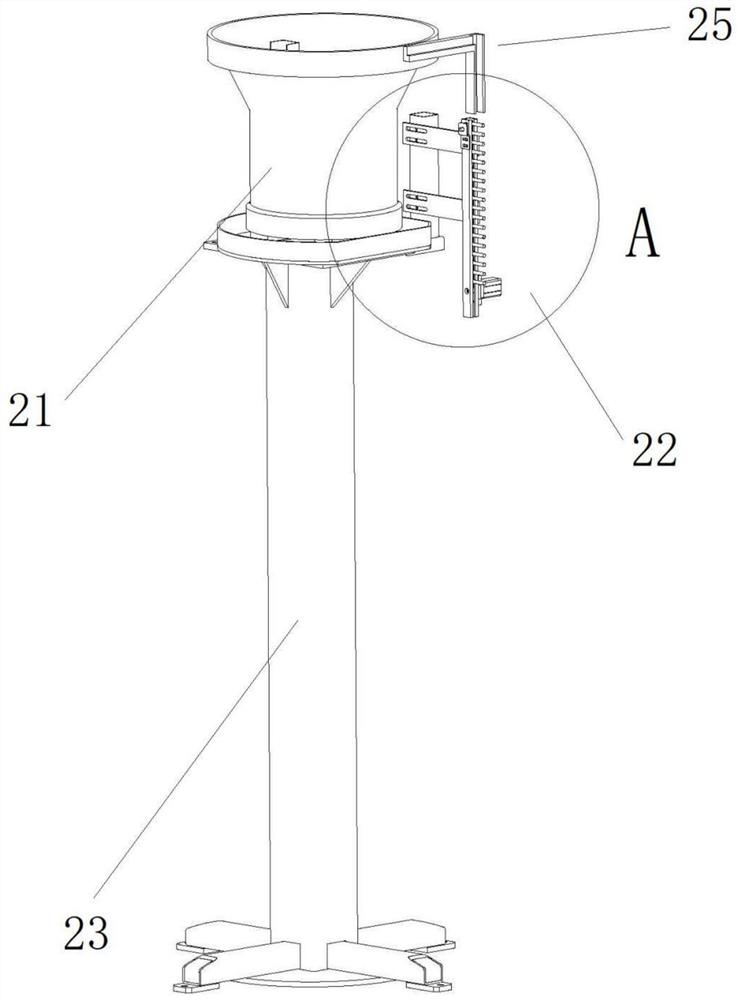

[0036] Such as Figure 6As shown, the bottom of the slideway 25 extends downwards and is connected to the second hinge storehouse 22, and other structures are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com