Acid tank sealing treatment system

A processing system and acid tank technology, applied in containers, packaging, transportation and packaging, etc., can solve the problems of low processing efficiency, poor use effect of acid mist removal, and high cost of acid mist removal equipment, so as to improve processing efficiency and avoid Acid fog diffuses, improves the effect of single treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

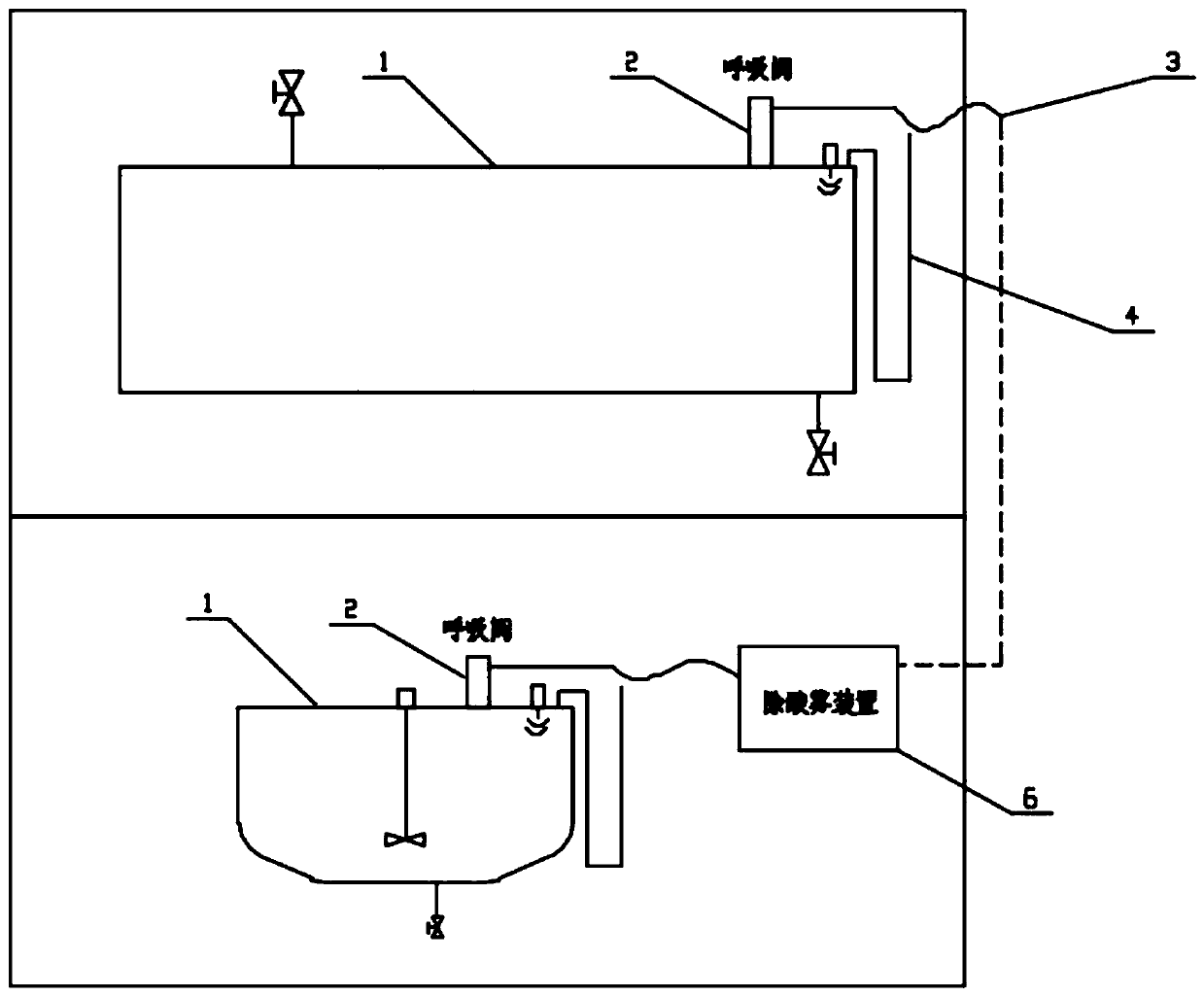

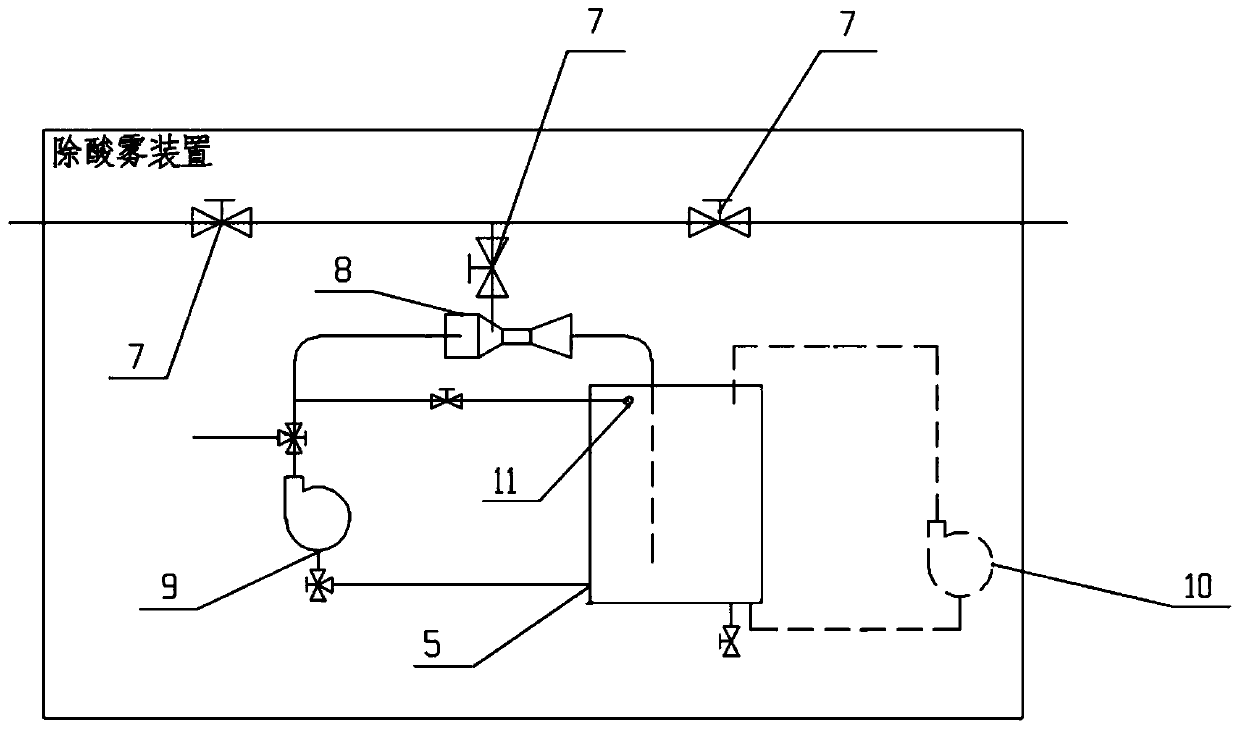

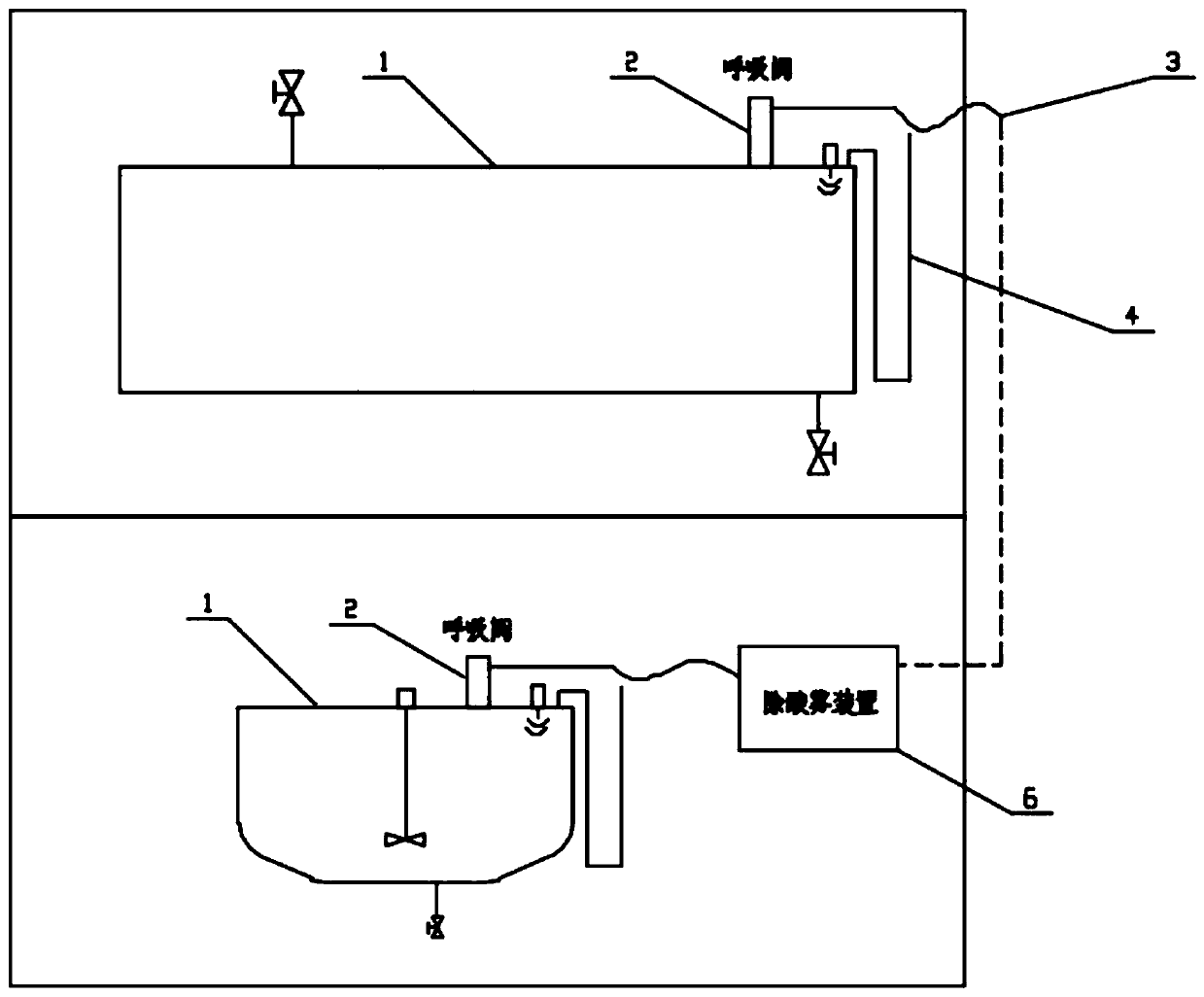

[0019] Such as Figures 1 to 2 As shown, an acid tank sealing treatment system includes a connecting pipe 3, an acid mist removal device 6 and an acid tank 1. The acid mist device 6 performs acid mist treatment. The acid tank sealing treatment system centrally processes the acid tanks 1 that may exist on the job site, improves the single treatment in the prior art, and improves the treatment efficiency. The acid tank 1 is connected to the acid mist removal device 6 through the connecting pipe 3 to process the acid mist, which realizes the sealing of the acid tank 1 on the job site and avoids the diffuse acid mist on the job site.

[0020] The connecting pipe 3 is connected to the acid mist removal device 6 through a first valve 7, and each connecting pipe 3 is provided with a first valve 7, and the first valve 7 is used to control the correspondingly connected acid tank 1 Whether it is connected to the acid mist removal device 6. An open valve (the first valve 7 ) is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com