Special secondary coating PBT color master batch for ultralow-shrinkage optical fibers

An optical fiber-specific, secondary coating technology, applied in the field of optical fiber materials, can solve the problems such as the inability to meet the requirements for the excess length and post-shrinkage of the loose tube of the optical cable, the modification cost and the large amount of modification production, and achieve good performance. , the effect of good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

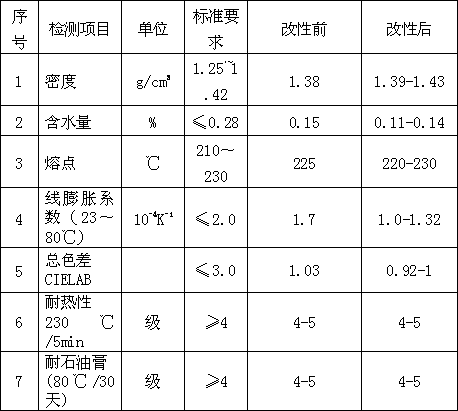

Image

Examples

Embodiment Construction

[0014] A special secondary coating PBT color masterbatch for ultra-low shrinkage optical fiber, including the following components, the mass ratio of each component is: anti-shrinkage agent 1-3%, PP nucleating agent 1-3%, toner 5-10% , heat stabilizer 1-3%, PBT base material 81-92%.

[0015] Further, the mass ratio of each component is: anti-shrinkage agent 1%, PP nucleating agent 3%, toner 7%, heat stabilizer 2%, PBT base material 87%.

[0016] Further, proceed according to the following process steps:

[0017] 1) Divide PP nucleating agent and PBT base material into one group, which is recorded as group A; divide other materials into another group, which is recorded as group B;

[0018] 2) Transport the materials of Group A to the A reactor for mixing evenly, and transport the materials of Group B to the B reactor for mixing evenly,

[0019] 3) After the materials of Group A and Group B are mixed uniformly, they are jointly transported to the C reactor, and mixed in the C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com