Transmission method and device of false twist compact spinning device and spinning frame

A concentrated spinning and false twisting technology, applied in spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problems of inconsistent movement directions, affecting operations, and increasing the complexity of equipment mechanisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

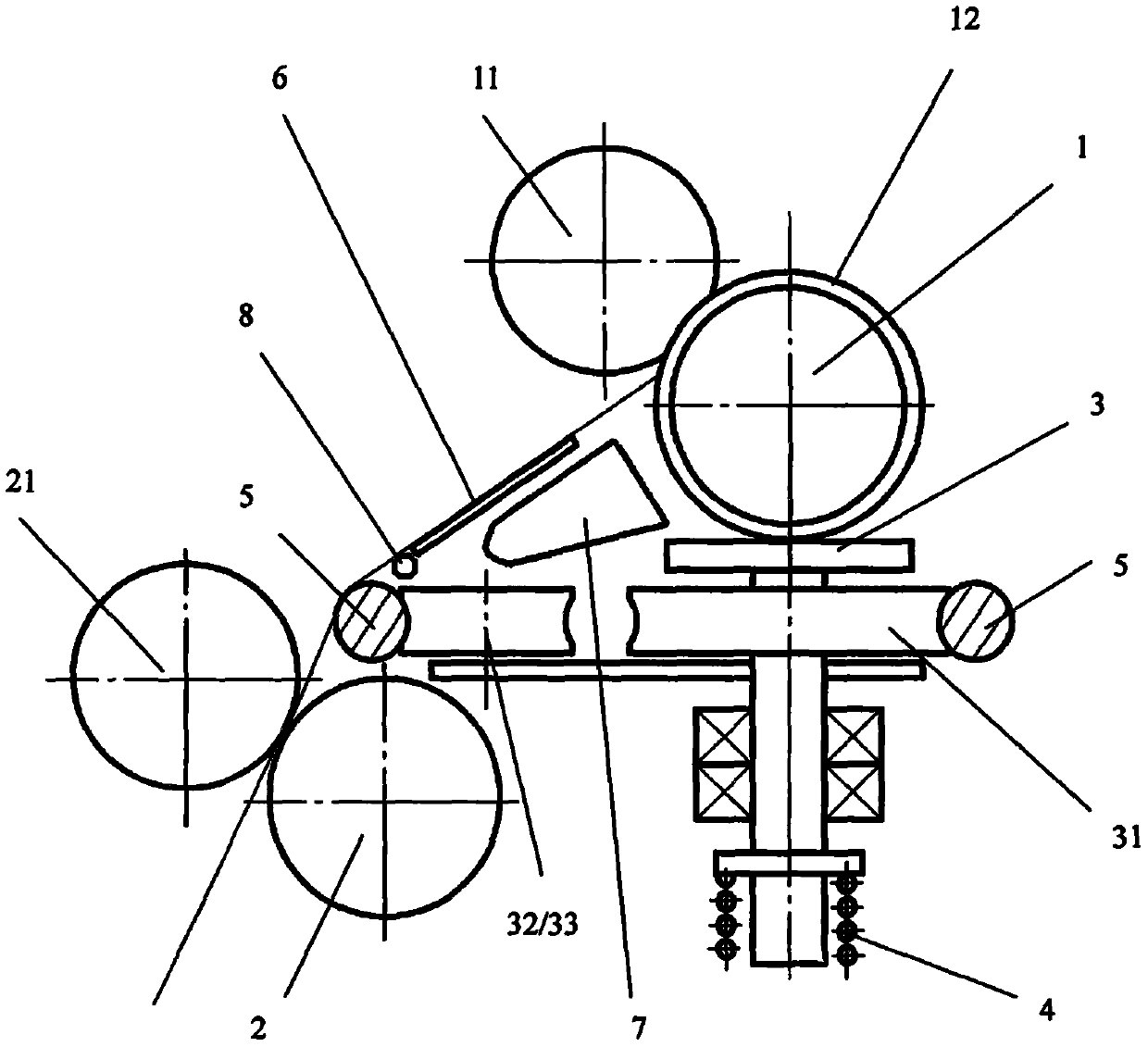

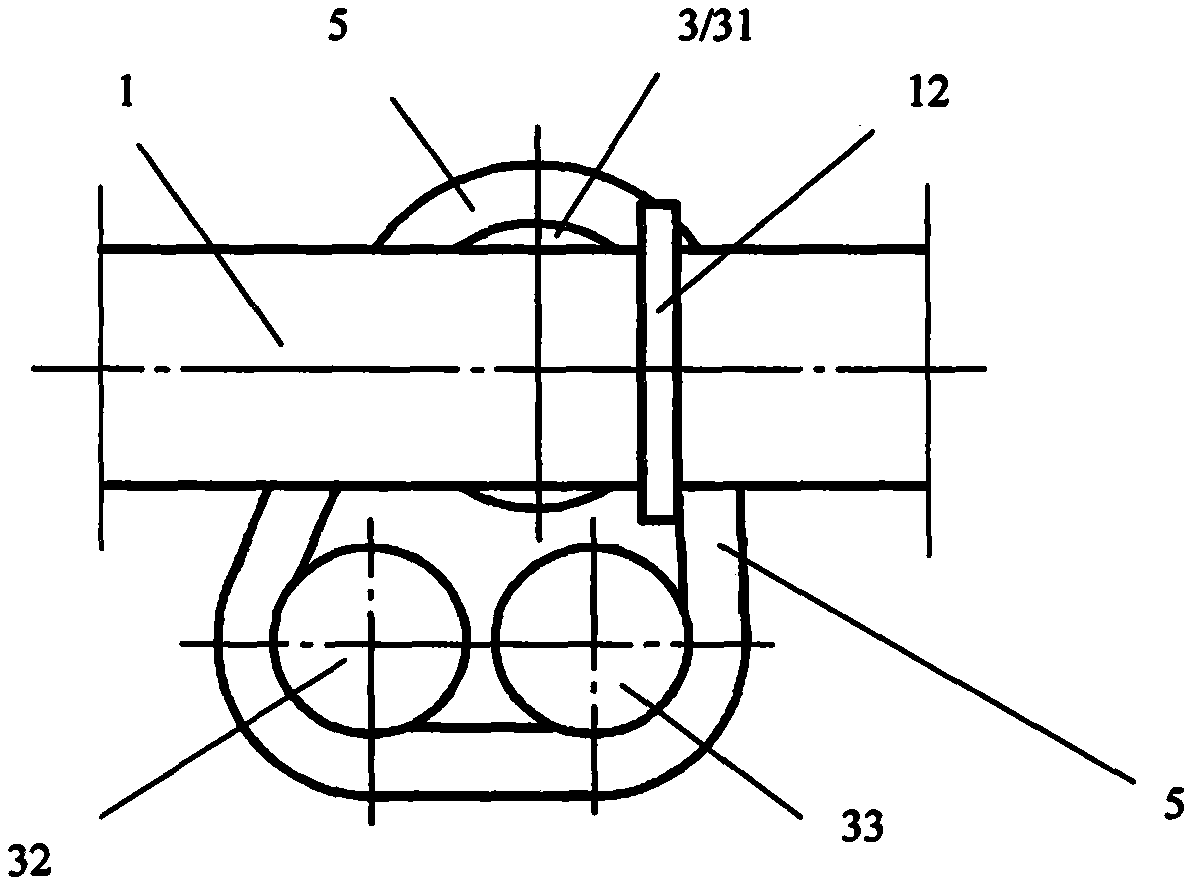

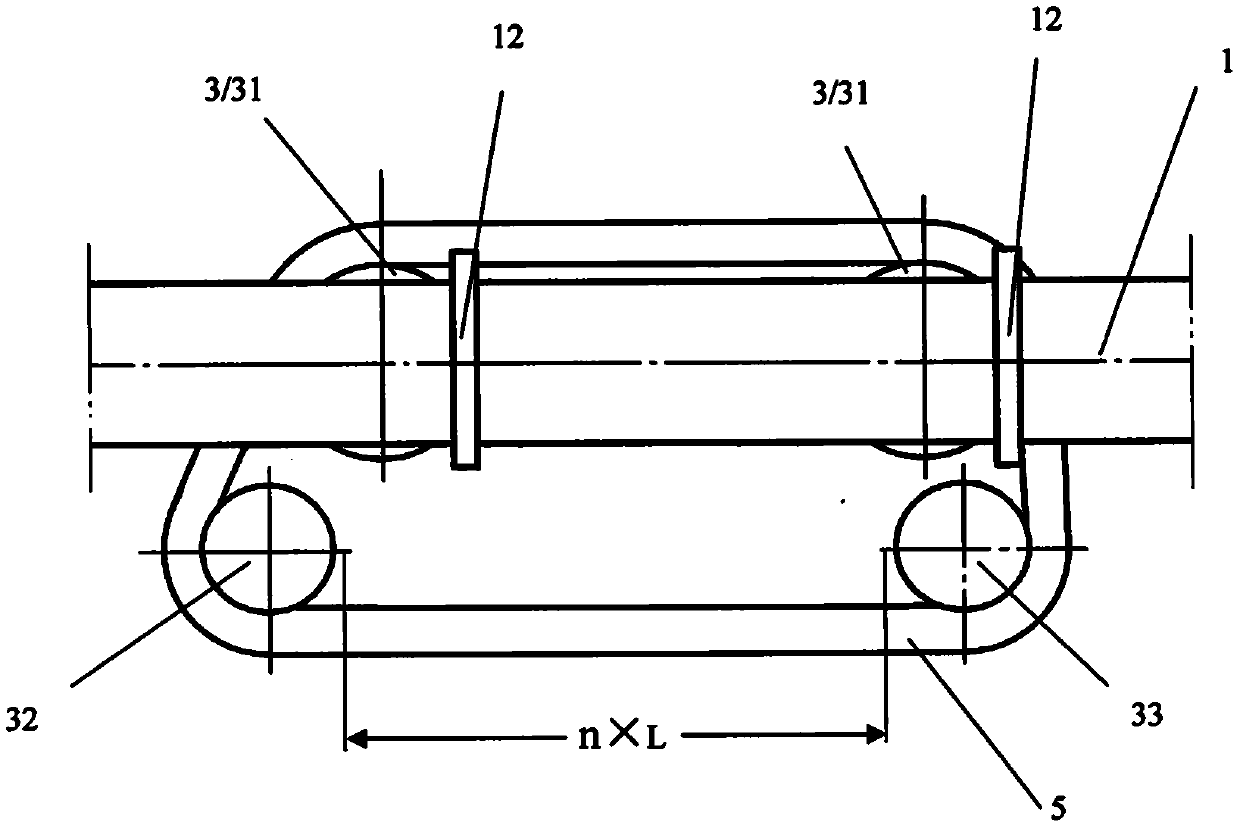

[0019] figure 1 Shown is a cross-sectional schematic diagram of a false twist compact spinning unit and a front roller of a false twist compact spinning device. The components of each false twist compact spinning unit include a lower pull-out roller 2, an upper pull-out roller 21, a friction ring 12, a friction Disk 3, friction belt active guide wheel 31, left friction belt passive guide wheel 32, right friction belt passive guide wheel 33, friction belt 5, pressure spring 4, hairiness gathering plate 6, cotton suction pipe 7, anti-twisting Picking needle 8, the friction ring 12 is misplaced to avoid the front top roller 11, fixedly sleeved on the front roller 1, and rotates synchronously with the front roller 1, and the friction disc 3 and the friction belt driving wheel 31 are coaxial structures, The two rotate synchronously, the axis of the friction disc 3 is perpendicular to the axis of the front roller 1, the end face of the friction disc 3 is in contact with the outer ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com