Metal air chamber driven grasping device and method of use thereof

The technology of grabbing device and air chamber is applied in the field of cylinder liner grabbing device, which can solve the problems of surface oxidation of cylinder liner, low temperature cold separation gap, temperature difference of cylinder liner, etc., so as to save parts, facilitate operation and use, and improve work The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

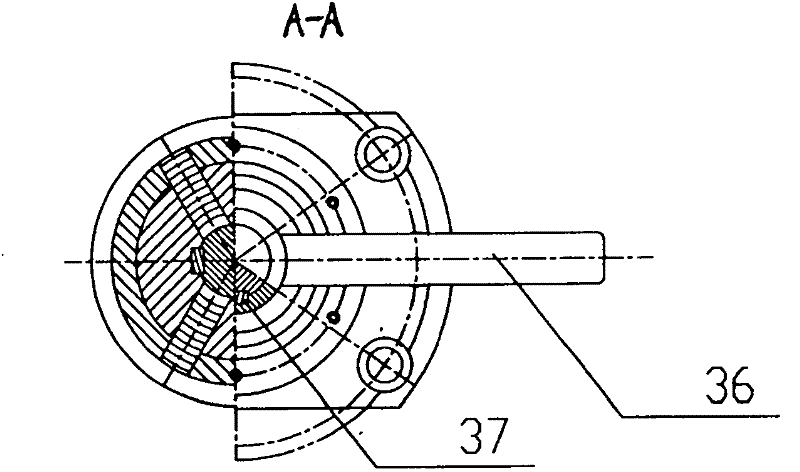

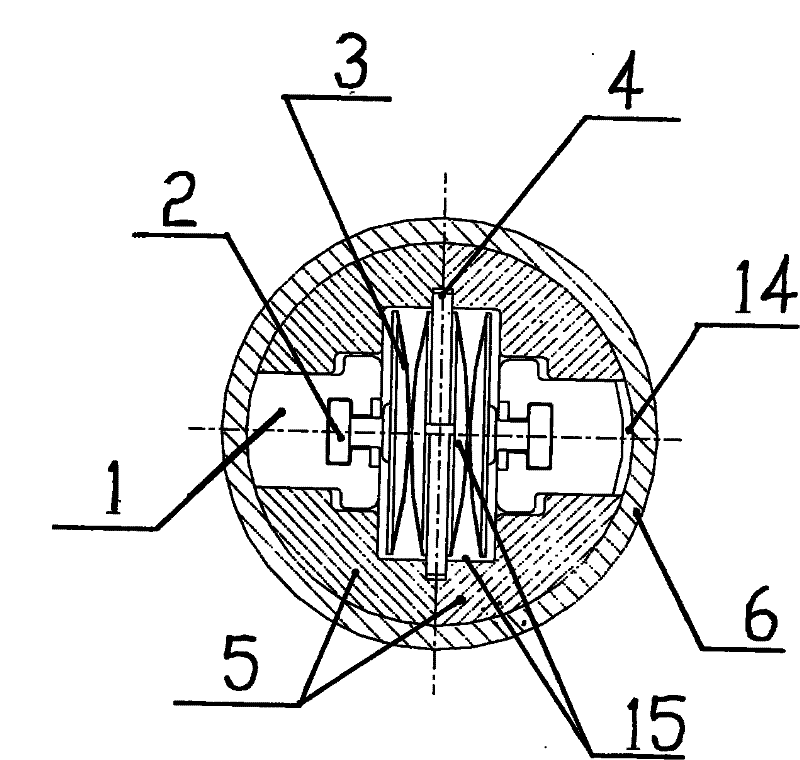

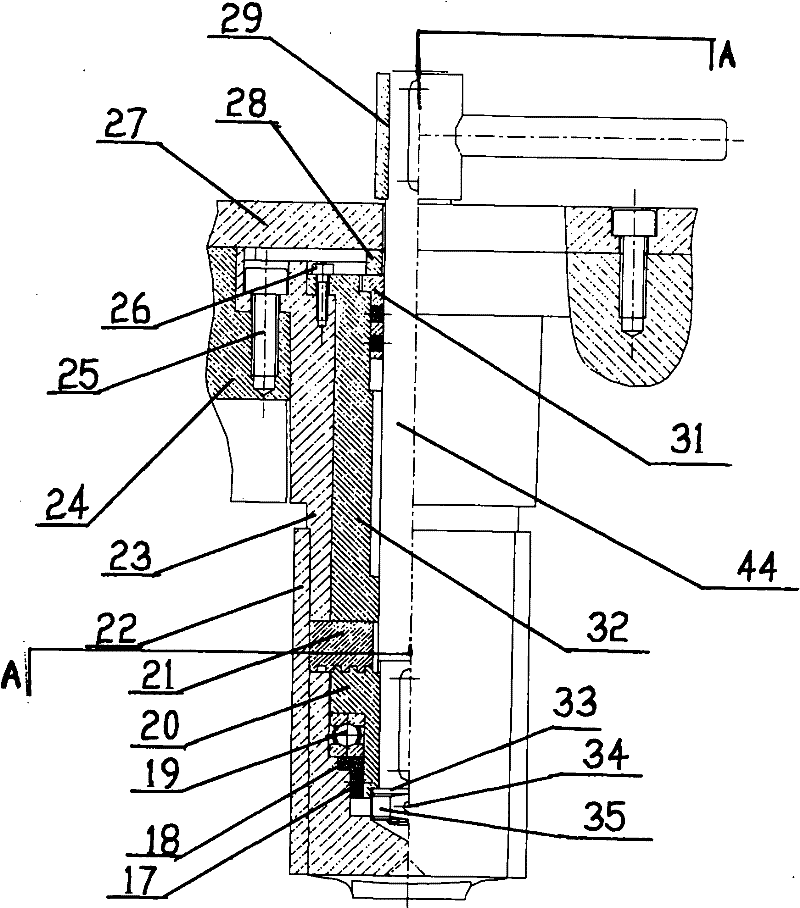

[0014] like figure 1 , figure 2 As shown, the metal slider 21 of the known mechanical plane screw transmission device is installed in the metal slider guide body 32, and the thread of the metal slider is screwed with the thread of the active plane screw flange 20, which is similar to a three-jaw chuck The plane spiral thread principle, the threaded body of the active plane spiral flange and the drive shaft 44 pass through the bar key 15 (see figure 2 ) Install the active plane spiral flange 20 on the high temperature resistant thrust bearing 19, and fix it in the hole of the copper sleeve 18, and the copper sleeve entity is inlaid with a graphite column 17 for high temperature lubrication. The lower end of the transmission shaft 44 forms a fixed connection between the driving flat spiral flange 20 and the transmission shaft 44 through the washer 33 , the nut 35 and the cotter pin 34 . The metal slider guide body 32 is fixed on the sunken platform of the metal core housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com