Rice huller and use method thereof

A paddy husking machine and rice paddy technology, applied in the field of paddy husking machines, can solve problems such as the inability to accurately control the linear speed of rubber rollers, the difficulty in controlling the quality of husking, and slowing down the wear speed of rubber rollers, so as to reduce the transmission chain and ensure husking Quality, slow down the effect of rubber roller wear speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

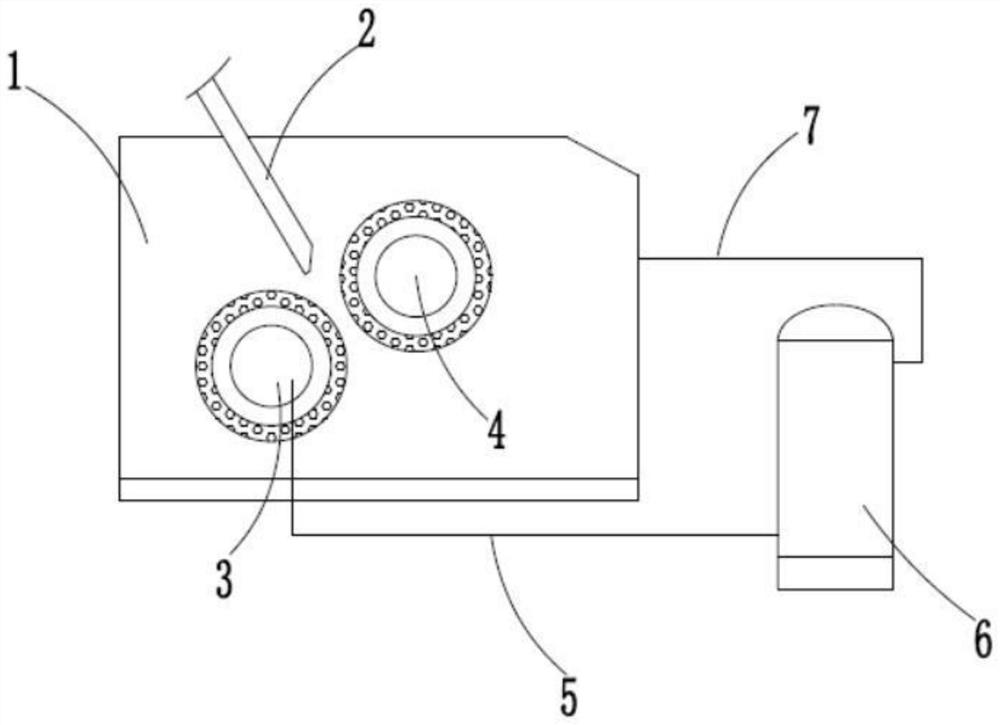

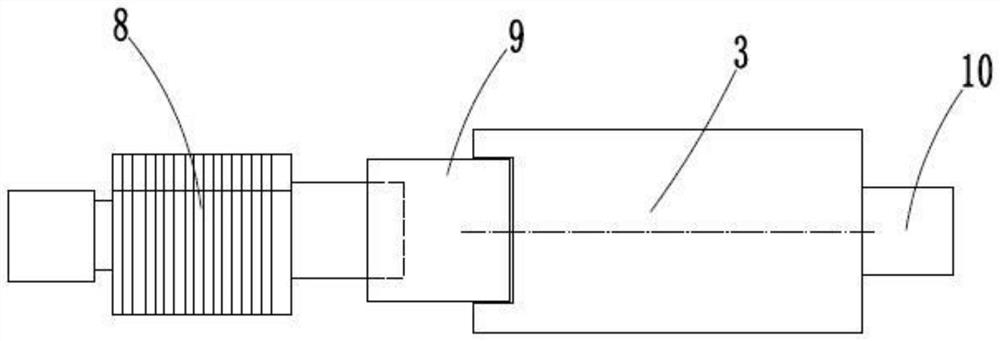

[0045] Such as Figure 1 to Figure 5 As shown, the huller of this embodiment includes a direct-drive motor 8 connected to the rubber roller, and the direct-drive motor 8 has a servo control system. The connecting part is used to connect the rotor of the direct-drive motor 8 and the rubber roller, so that the roller of the rubber roller is concentric with the axis of the drive shaft of the direct-drive motor 8 .

[0046] In this embodiment, the rice huller uses a direct-drive motor to improve the synchronous efficiency of the motor and the rubber roller, ensure the transmission effect, and avoid the transmission and positioning problems caused by the conversion of the drive source by the gearbox. The axis line of the drive shaft of the drive motor is set in parallel, reducing the transmission chain and simplifying the transmission structure, which is convenient for precise control of the linear speed of the roller, ensures the quality of shelling, and slows down the wear speed ...

Embodiment 2

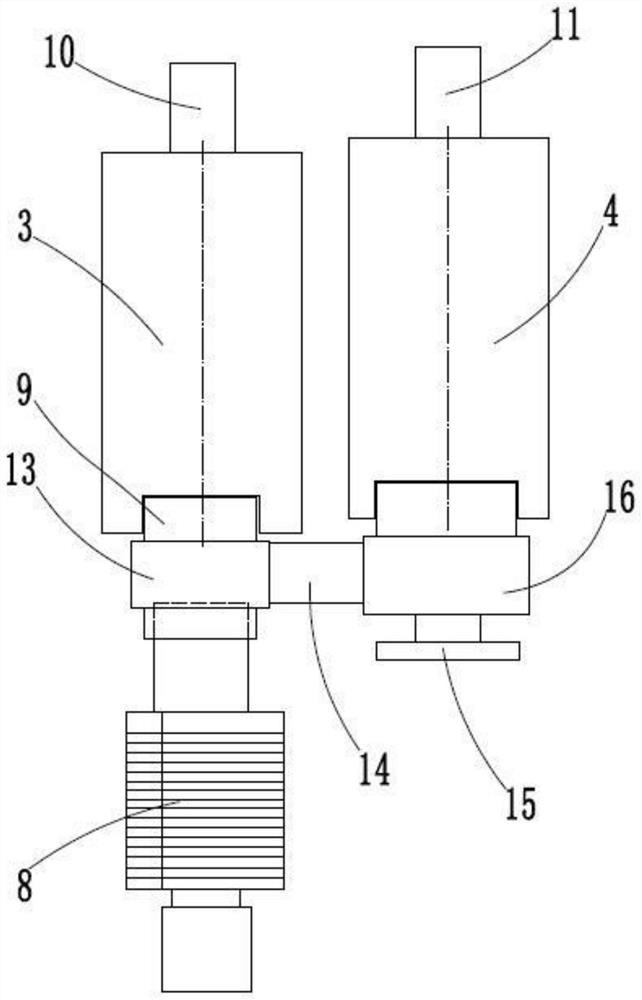

[0048] Such as Figure 1 to Figure 5 As shown, according to the huller described in Embodiment 1, the huller of this embodiment includes two rubber rollers, the two rubber rollers are respectively the first rubber roller 3 and the second rubber roller 4, and the first rubber roller The roller 3 and the second rubber roller 4 are provided with corresponding direct-drive motors 8 respectively, and roller diameter sensors are provided on both rubber roller sides. The change of the diameter of the rubber roller is measured by the roller diameter sensor and transmitted to the controller. The controller then accurately controls the speed of the direct drive motor, and precisely adjusts the linear speed of the two rubber rollers to ensure a constant linear speed difference between the two rollers. Then the shelling quality is guaranteed, and the problem of shelling quality decline caused by drum wear is solved. According to relevant principles, the line speed is directly proportiona...

Embodiment 3

[0050] Such as Figure 1 to Figure 5 As shown, according to the rice huller described in Embodiment 1, the two rubber rollers in this embodiment are respectively the first rubber roller 3 and the second rubber roller 4, and the first rubber roller 3 is connected to the direct drive motor 8 , between the direct-drive motor 8 and the first rubber roller 3, there is a driving connecting sleeve 9, a pulley 13 is provided on the driving connecting sleeve 9, a driven pulley sleeve 16 is arranged on the second rubber roller 4, and A transmission belt 14 is provided, and a roller diameter sensor is arranged on the first rubber roller 3 . In this scheme, the two rubber rollers are respectively driven by the driving source to rotate, and one of the rubber rollers is driven to rotate by the driving source, and the other rubber roller is passively rotated through the belt drive, which reduces the power source and solves the problem that the two rubber rollers are respectively equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com