A method of using open shield machine to construct underground box culvert

A shield machine and an open technology, applied in underground chambers, earthwork drilling, shaft equipment, etc., can solve problems such as heavy on-site workload, affecting the assembly accuracy of underground box culverts, and difficulty in ensuring the quality of underground box culvert pouring on site. , to achieve the effect of reducing noise and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

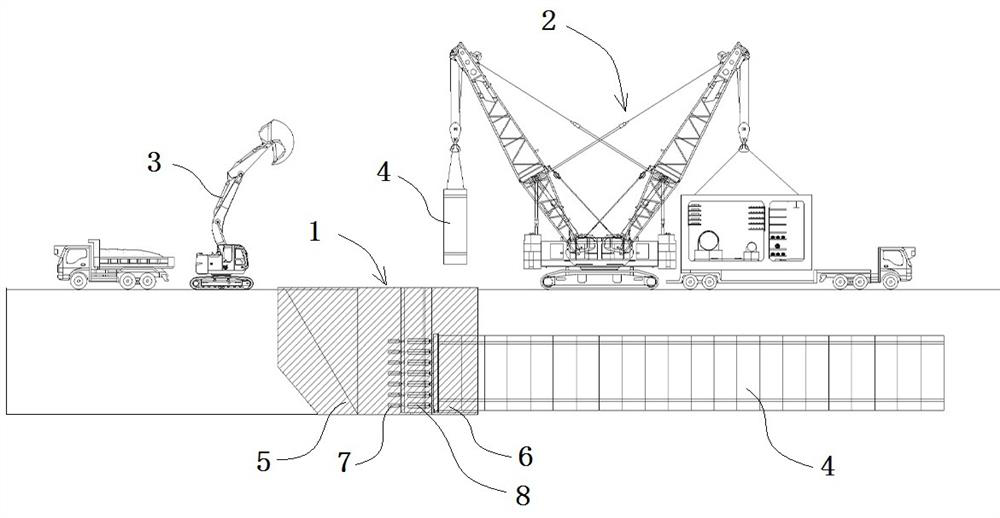

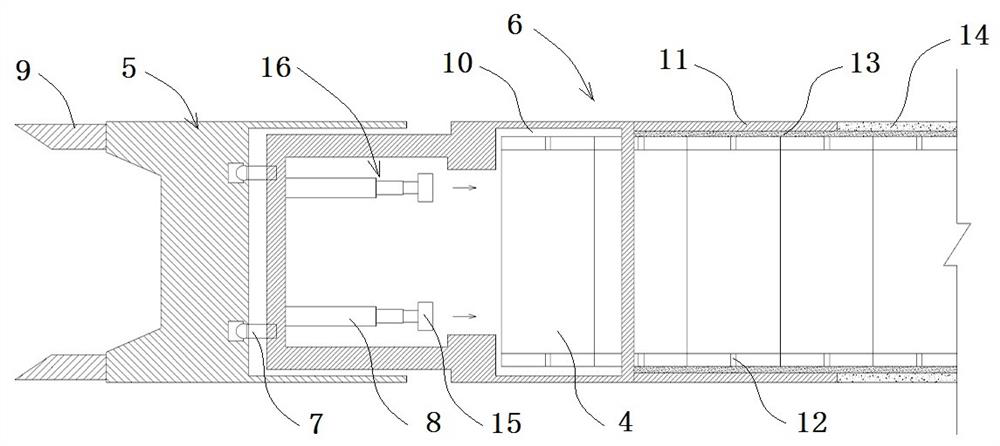

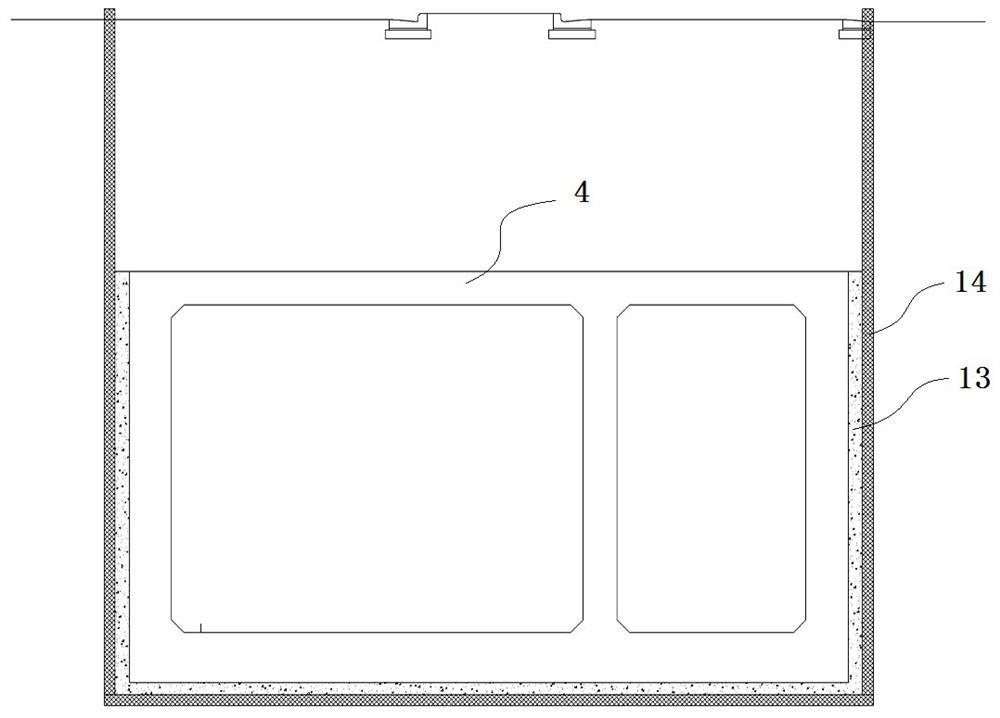

[0024] Embodiment 1: as figure 1 , 2 , 3, this embodiment specifically relates to a method for using an open shield machine to construct an underground box culvert, and the method mainly includes the following steps:

[0025] (1) Prepare various construction equipment and underground box culvert components, mainly including open shield machine 1, culvert body hoisting mechanism 2, excavator 3, backfill excavator and several culvert bodies 4; among them:

[0026] The open shield machine 1 includes the front tunneling cabin 5 and the rear body installation cabin 6 hinged by the hinge mechanism 7. Through the left and right, up and down travel differences of the hinge mechanism 7, the front tunnel 5 and the rear body installation Relative bending can be produced between cabins 6 for curved construction;

[0027] The front excavation cabin 5 can cut and excavate the soil, and there are sliding type soil retaining arms 9 on both sides of its front. Wedge-shaped surface, while th...

Embodiment 2

[0054] Embodiment 2: as Figure 4 , 5 , 6, the present embodiment specifically relates to a method for using an open shield machine to construct an underground box culvert, and the method mainly includes the following steps:

[0055] (1) Prepare various construction equipment and underground box culvert components, mainly including open shield machine 17, culvert body hoisting mechanism 19, excavator 18, backfill excavator and several culvert bodies 23; among them:

[0056] The open shield machine 17 includes a front tunneling cabin 20, a middle reaction support cabin 21 and a rear culvert installation cabin 22 connected in sequence, wherein:

[0057] The front excavation cabin 20 can cut and excavate the soil, and the two sides of its front are provided with sliding soil retaining arms 26. wedge-shaped surface, and the rear end of the sliding type soil retaining arm 26 is driven by a hydraulic cylinder (not shown in the figure) located in the front excavation cabin 20, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap