Barrel type paper folding rebounding mechanism containing interval structure

A technology with a gap and a barrel shape, which is used in mechanical equipment, low internal friction springs, springs/shock absorbers, etc., can solve the problems of insufficiency, difficulty in guaranteeing service life, high cost, etc., and achieves low cost and simple and convenient production. , the effect of good structural mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The purpose and effects of the present invention will become clearer by describing the present invention in detail according to the accompanying drawings and preferred embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

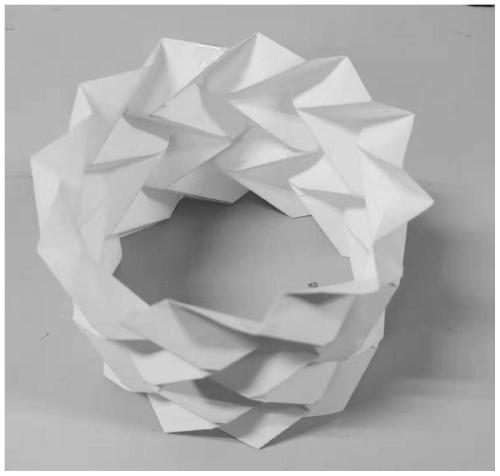

[0022] Such as figure 1 As shown, the paper-based model of the tubular origami rebound mechanism with gap structure of the present invention is formed by folding plane materials according to specially designed creases, and has certain rigidity and elasticity. When the tubular origami rebounds When the mechanism is squeezed in the axial direction, it will generate compression deformation along the axis direction and generate resilience at the same time;

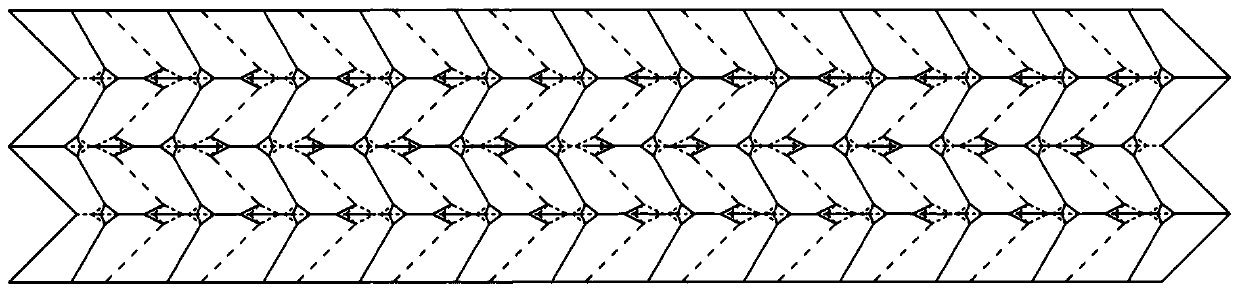

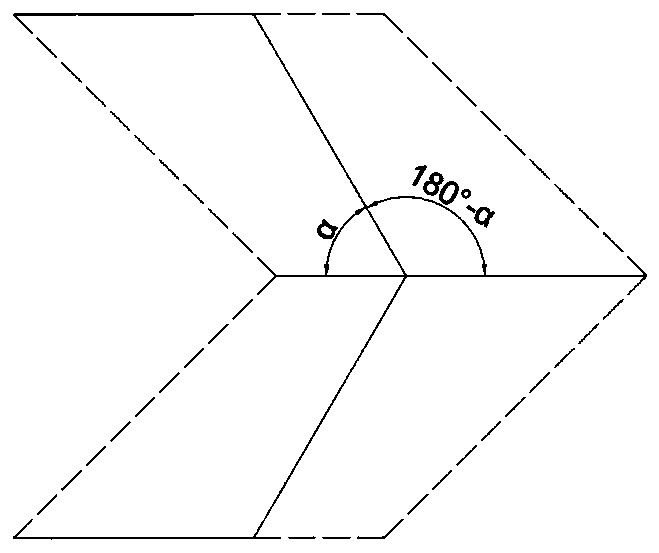

[0023] The tubular origami springback mechanism is a periodically repeated structure in the circumferential direction, and the specific plane crease diagram of the springback mechanism of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com