Intelligent screw based on optical fiber sensing and application thereof

A technology of optical fiber sensing and screw, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of bridge safety hazards, the difficulty of realizing real-time monitoring and early warning of cable clamp structures, and the inability to provide real-time data of screw/suspension rods, etc., to ensure normal and stable The effect of operation, healthy and rapid development guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

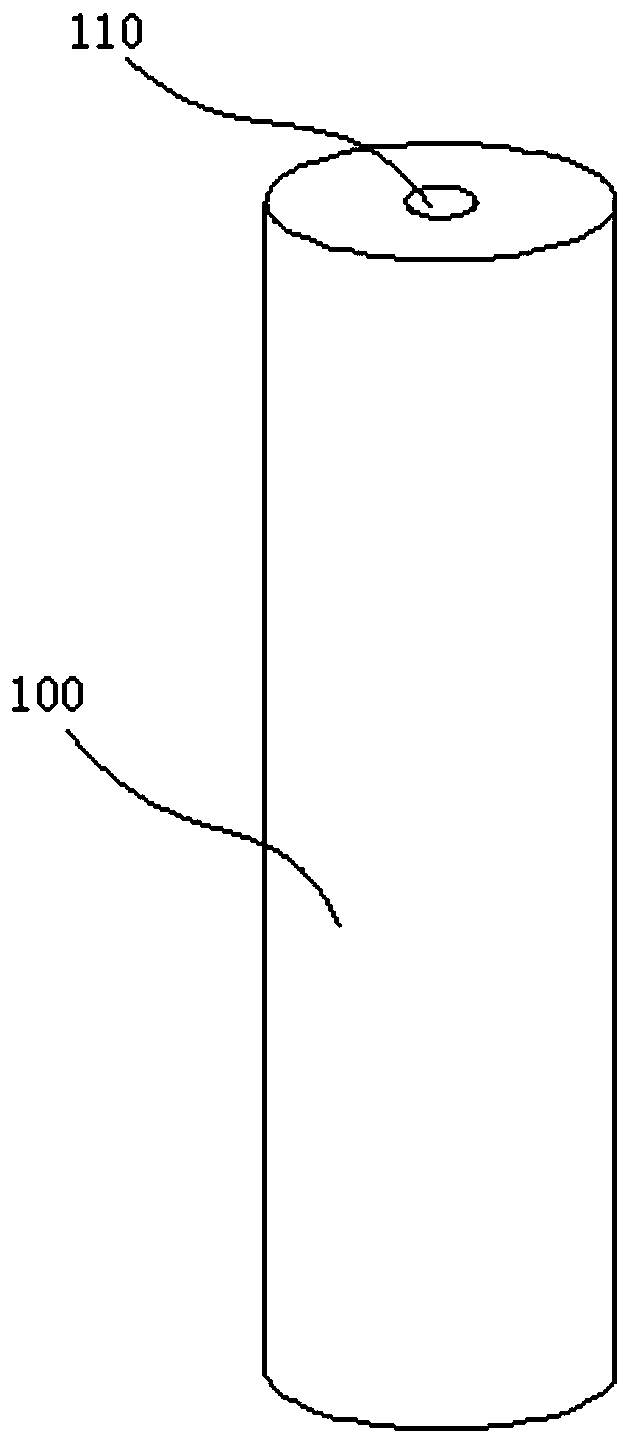

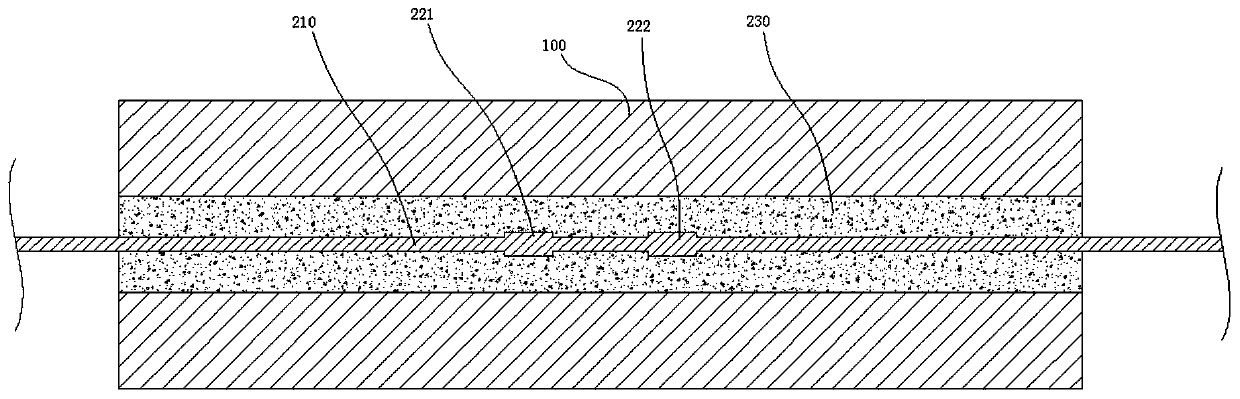

[0021] combine figure 2 with 3 As shown, this embodiment provides a smart screw based on optical fiber sensing, which includes a screw body 100, and the middle part of the screw body 100 is provided with an installation through hole 110 penetrating in the axial direction; the installation through hole 110 is provided with an optical fiber 210, The part of the optical fiber 210 located in the installation through hole 110 is inscribed with a first fiber Bragg grating 221 and a second fiber Bragg grating 222 at intervals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com