Mixing pile quality evaluation method based on construction remote monitoring system

A technology for remote monitoring and quality assessment, applied in infrastructure engineering, infrastructure testing, sheet pile walls, etc. It can solve problems such as low sampling frequency, failure to find problems, and inability to comprehensively evaluate, and achieve good accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

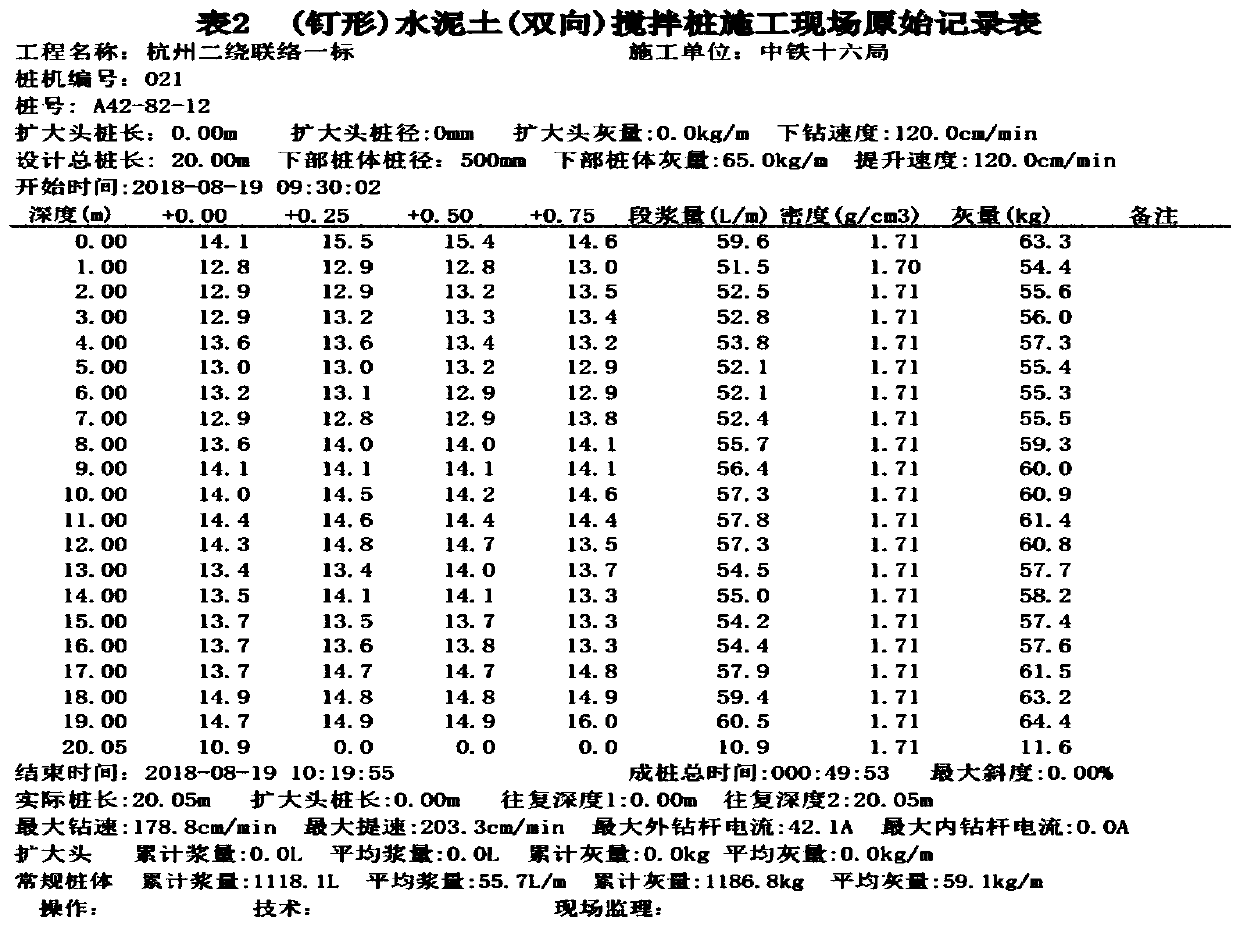

[0056] Example 1: Combining Figure 1-Figure 5 , the present invention is further described:

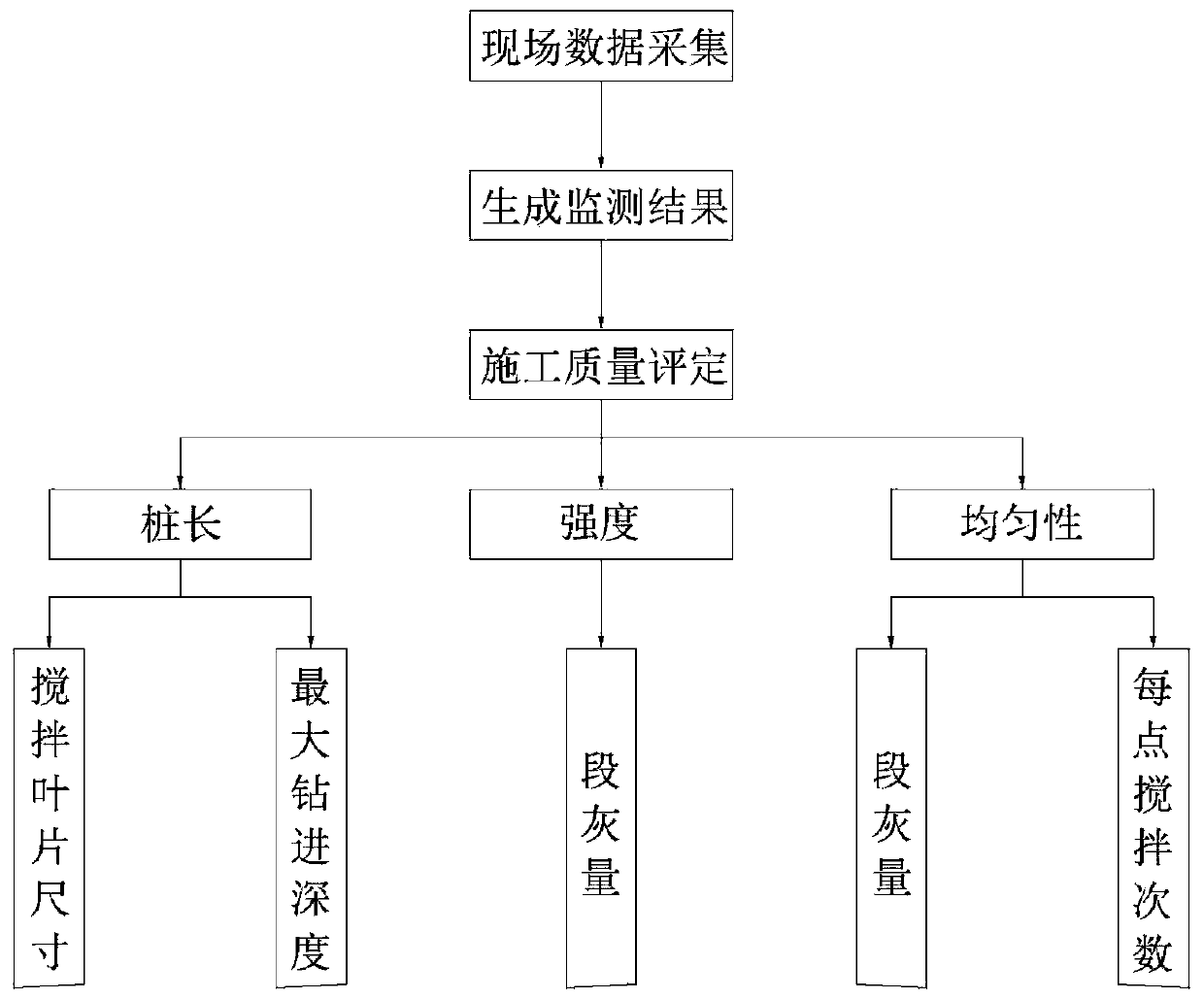

[0057] figure 1 It is the detailed implementation process of the monitoring method. The first is to collect on-site data, and then use the monitoring instrument to generate monitoring results, and then carry out construction quality assessment. The construction quality evaluation is mainly through the comprehensive evaluation of three indicators, which are pile length, strength and uniformity indicators.

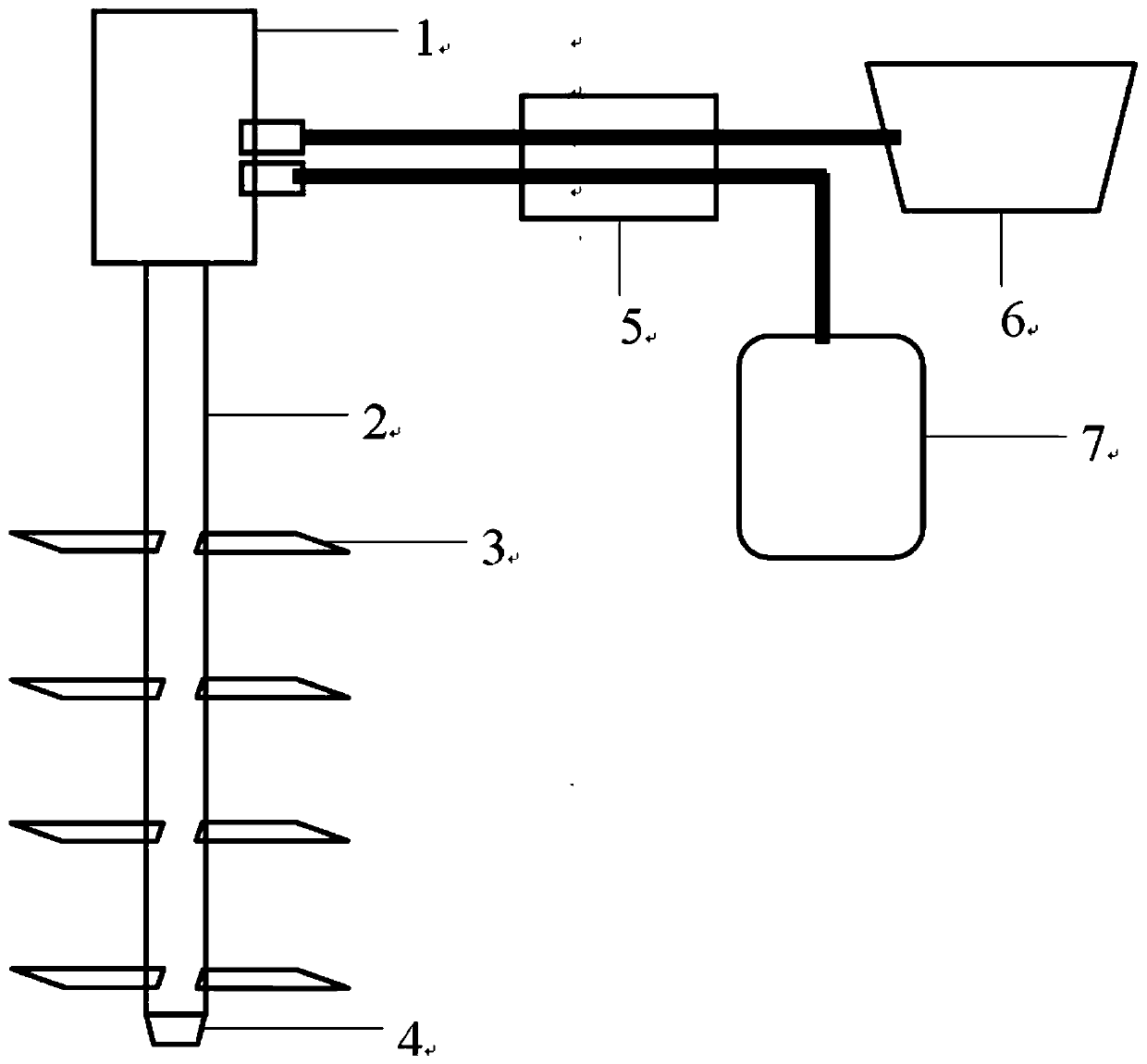

[0058] figure 2 In order to monitor the connection mode of the equipment, the drill pipe 2 is provided with a stirring head 3, the bottom of the drill pipe 2 is provided with a depth sensor 4, and the top is provided with an inclination sensor 1 and a density sensor 5, and the inclination sensor 1, the density sensor 5 and the depth sensor 4 The deep mixing pile monitor 7 is respectively connected, the inclination sensor 1 can record the pile body inclination and the number o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com