A kind of non-aqueous electrolyte and preparation method thereof and application in lithium ion battery

A non-aqueous electrolyte and lithium salt technology, which is applied in the field of lithium-ion batteries, can solve problems that need to be further improved, and achieve excellent fast charging performance and cycle performance, good lithium-conducting performance, and good film-forming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

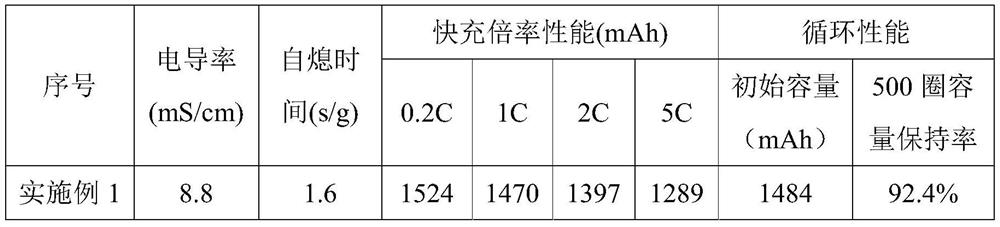

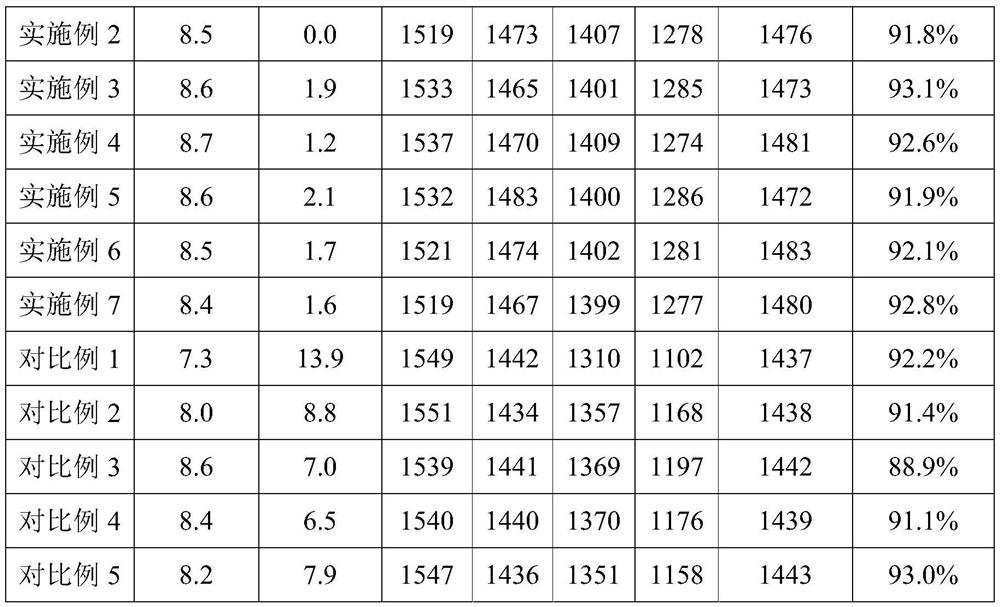

Examples

Embodiment 1

[0044] A non-aqueous electrolyte comprising lithium salts, organic solvents and additives,

[0045] The organic solvent includes: 20% diethyl carbonate DEC, 20% ethyl methyl carbonate EMC, 20% ethylene carbonate EC, 10% trimethylsilyl substituted propylene carbonate TMSPC and 30% tetrafluoroethylene Base-tetrafluoropropyl ether HFE;

[0046] Lithium hexafluorophosphate whose lithium salt is 2mol / L;

[0047] Based on the total mass of the electrolyte as 100%, the additives include 1.0% lithium difluorophosphate LiPO 2 f 2 , 1.0% vinyl sulfate DTD, 3.0% tris(2,2,2-trifluoroethyl)phosphate TFEP.

[0048] The preparation steps of non-aqueous electrolyte are as follows:

[0049] S1. Dewatering of raw materials: In an anhydrous and oxygen-free glove box, use a 4A (5A) water separation sieve to dewater the solvent, diluent, and additives. The treatment time is 20 to 30 hours, and the water content is less than 10ppm. Solvents, thinners and additives;

[0050] S2. Preparation of...

Embodiment 2

[0055] A non-aqueous electrolyte comprising lithium salts, organic solvents and additives,

[0056] The organic solvent includes: 25% diethyl carbonate DEC, 25% ethyl methyl carbonate EMC, 20% ethylene carbonate EC, 10% trimethylsilyl substituted butylene carbonate TMSBC and 20% tetrafluoroethylene Ethyl-tetrafluoropropyl ether HFE;

[0057] Lithium hexafluorophosphate whose lithium salt is 2mol / L;

[0058] Based on the total mass of the electrolyte as 100%, the additives include 1.0% lithium difluorophosphate LiPO 2 f 2 , 1.0% vinyl sulfate DTD, 3.0% tris(2,2,2-trifluoroethyl)phosphate TFEP.

[0059] The preparation steps of the non-aqueous electrolyte are as in Example 1.

[0060] Battery assembly and testing:

[0061] Inject the above electrolyte into the dried 2000mAh LiNi 0.8 co 0.1 mn 0.1 o 2 / Graphite soft-packed batteries, the batteries are routinely divided after being placed at 45°C, formed by high-temperature fixtures and sealed twice.

[0062] Then the b...

Embodiment 3

[0064] A non-aqueous electrolyte comprising lithium salts, organic solvents and additives,

[0065] The organic solvent includes: 25% diethyl carbonate DEC, 25% ethyl methyl carbonate EMC, 20% ethylene carbonate EC, 10% trimethylsilyl substituted propylene carbonate TMSPC and 20% tetrafluoroethylene Base-tetrafluoropropyl ether HFE;

[0066] Lithium hexafluorophosphate whose lithium salt is 2mol / L;

[0067] Based on the total mass of the electrolyte as 100%, the additives include 1.0% lithium difluorophosphate LiPO 2 f 2 , 1.0% vinyl sulfate DTD, 3.0% tris(2,2,2-trifluoroethyl)phosphate TFEP.

[0068] The preparation steps of the non-aqueous electrolyte are as in Example 1.

[0069] Battery assembly and testing:

[0070] Inject the above electrolyte into the dried 2000mAh LiNi 0.8 co 0.1 mn 0.1 o 2 / Graphite soft-packed batteries, the batteries are routinely divided after being placed at 45°C, formed by high-temperature fixtures and sealed twice.

[0071] Then the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com