High-speed rail platform boundary measurement system

A measurement system and platform technology, which is applied in the direction of railway vehicle shape measuring instrument, measuring distance, measuring device, etc., can solve the problems of limit data error, left and right shaking of measuring device, and large amount of data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

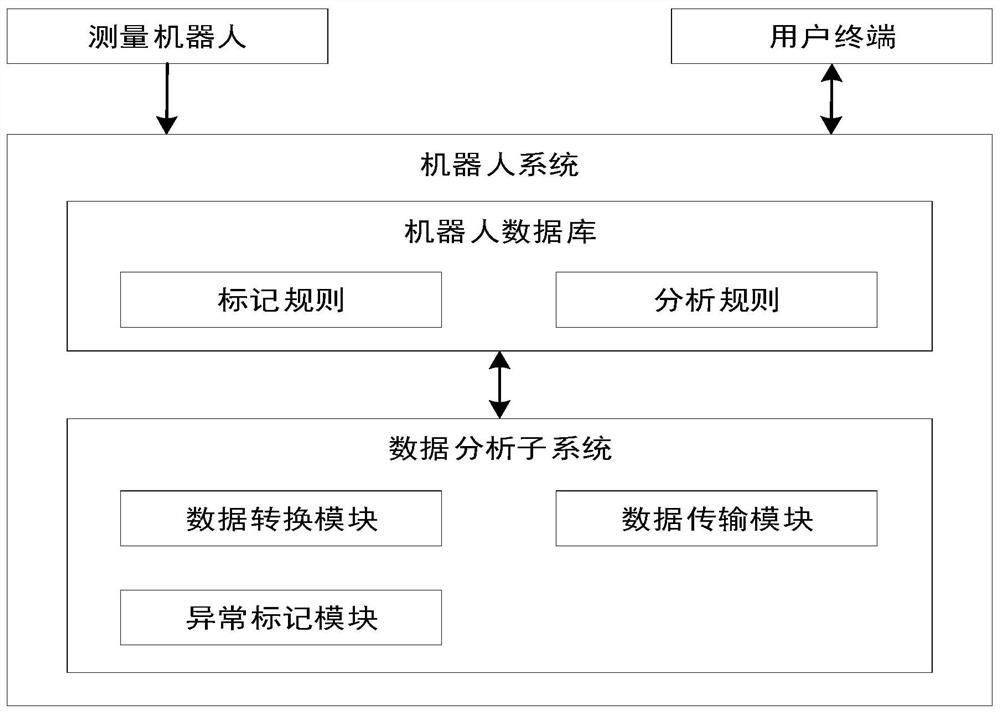

[0040] The high-speed rail platform boundary measurement system includes a measurement robot, a robot system mounted on the measurement robot, and a user terminal.

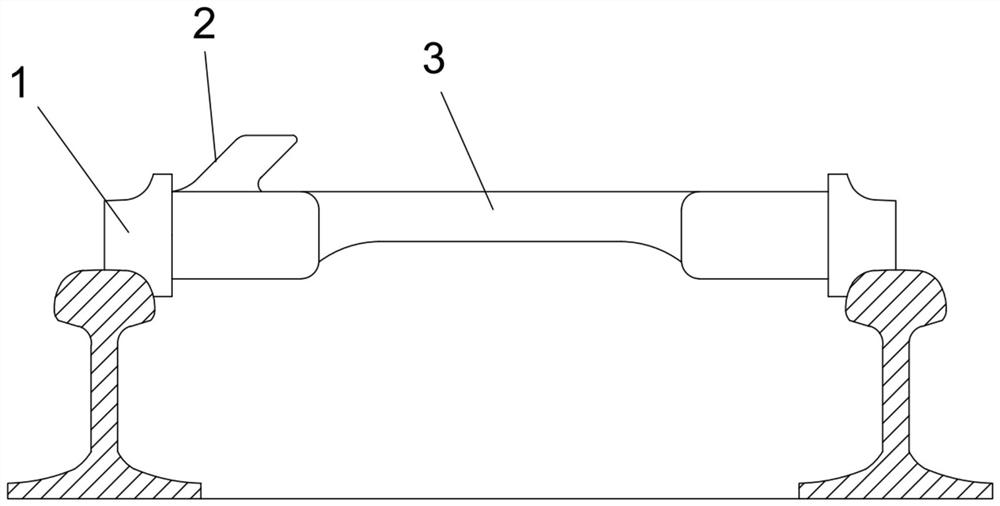

[0041] as attached figure 1 As shown, the measuring robot includes a robot main body 3. There are control chambers on both sides of the robot main body 3. A rotating motor is arranged in the control chamber. The output shaft of the rotating motor is connected to the roller through a coupling. out of the control cavity, and is welded with a roller 1, the outer wall of the roller 1 is in contact with the upper end surface of the track, the end of the roller 1 close to the robot body 3 extends outward from the axial direction of the roller 1 to form a blocking part, and the blocking part is far away from the side of the robot body 3 side against the track. In this embodiment, two rollers 1 are provided on both sides of the main body of the robot 3, and the blocking parts are located at one end of the rollers 1 close...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that in order to facilitate the staff to find the platform area represented by the abnormal data in time, it is also necessary to obtain the mileage data of the measuring robot and display the mileage data synchronously. Quickly find the platform area based on the mileage data corresponding to the abnormal data.

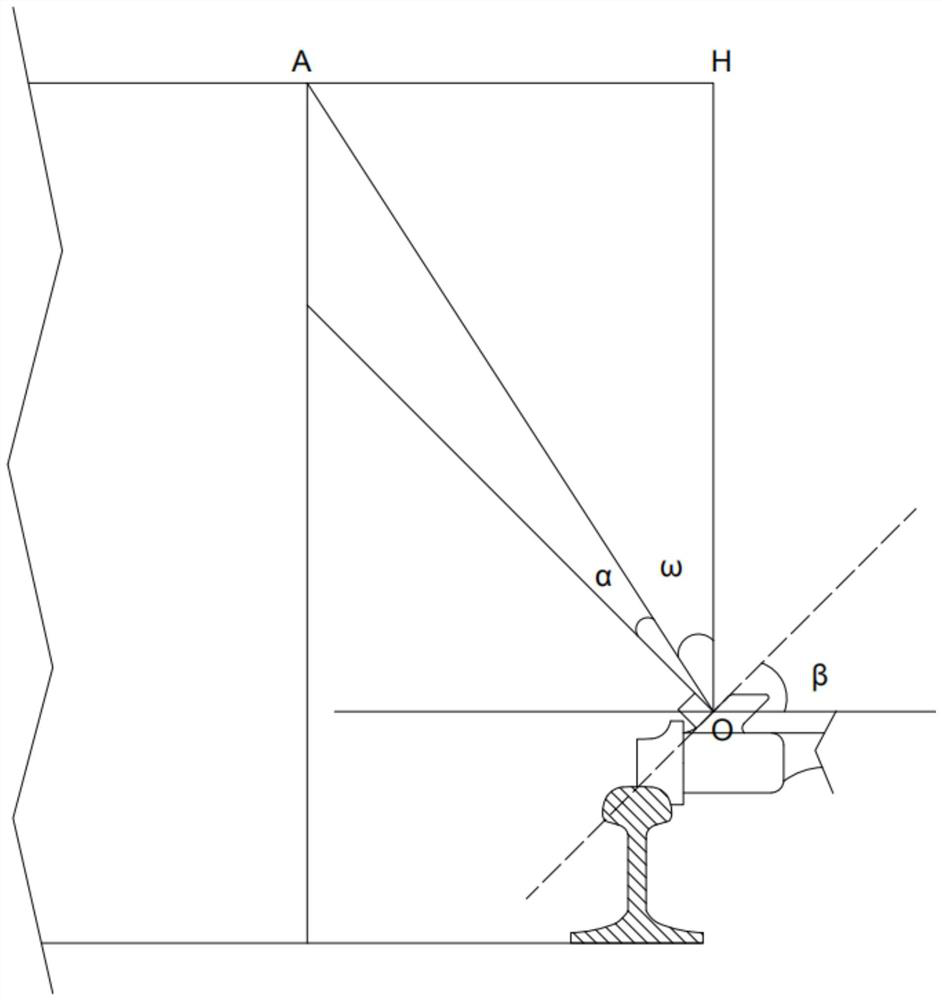

[0052] The laser is preset with a ranging sampling frequency, and the laser obtains the measured inclination and the measured distance according to the ranging sampling frequency, and sends the measured inclination and the measured distance to the controller. The controller is preset with a mileage sampling frequency, and obtains the data of the encoder of the rotating motor as the mileage data according to the mileage sampling frequency. The controller integrates the measured inclination angle and the measured distance into measurement data, wherein the distance measurement sampling frequency is highe...

Embodiment 3

[0058] The difference between this embodiment and Embodiment 1 is that it also includes a background server, such as the attached Figure 6 As shown, the background server includes a server database, a primary filtering module, a secondary filtering module, and a three-dimensional modeling module, and filtering rules are pre-stored in the server database.

[0059] The robot system is used to send the measurement data, tilt angle and marked limit data to the background server, and the background server is used to store the received measurement data, tilt angle and marked limit data in the server database. In other embodiments, the measurement robot may also send the measurement data and inclination angle to the background server, and the background server generates the limit data according to the analysis rules, and marks the limit data according to the marking rules, so as to obtain the marked limit data.

[0060] The primary filter module is preset with a filter difference, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com