Novel cargo boom mounting mode of boom tower crane

A technology of a boom tower crane and installation method, which is applied to cranes and other directions, can solve the problems of low safety, low installation efficiency, and long time consumption, and achieve the effects of high safety, high installation efficiency, and reduction of work and work time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

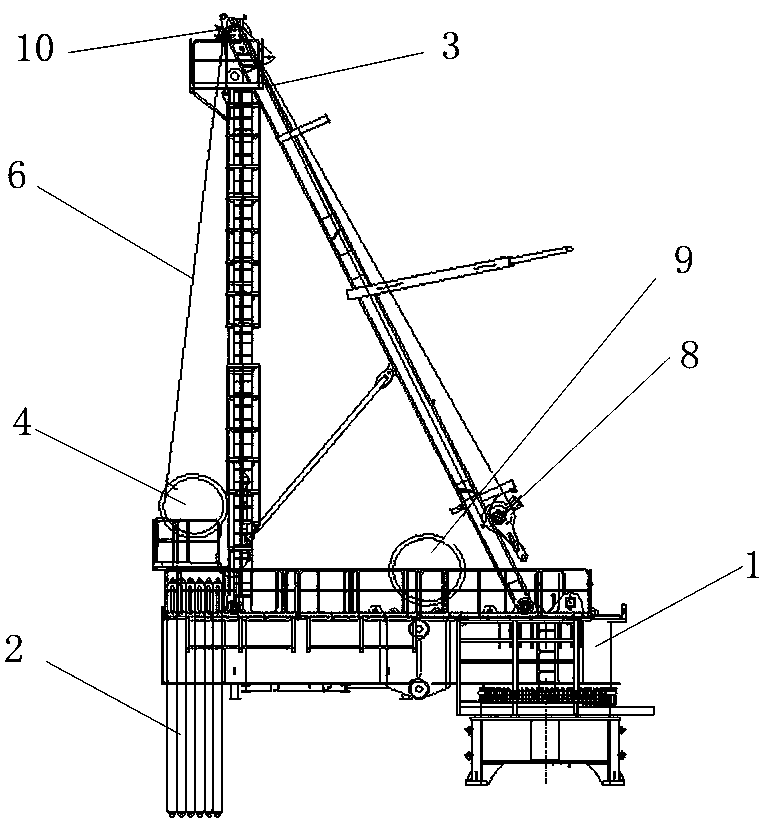

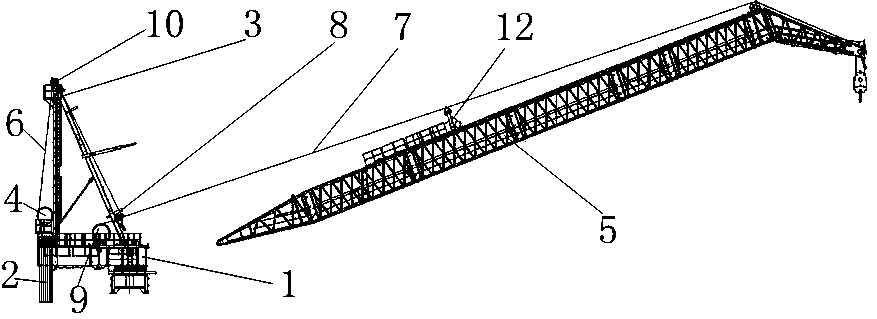

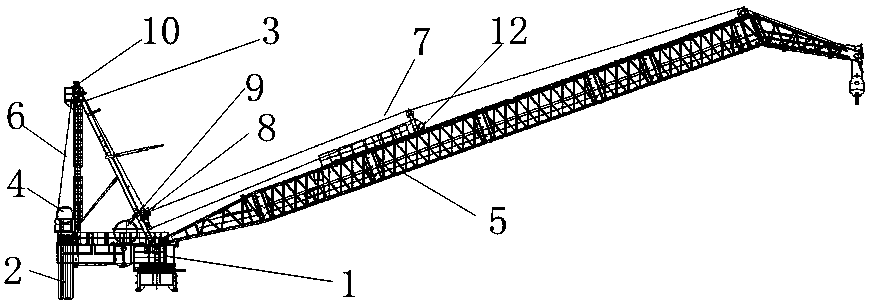

[0021] like Figure 1 to Figure 5 A new boom installation method of the boom tower crane is shown. After the boom tower crane completes the installation of the slewing platform 1, the counterweight 2, the tower top 3 and the luffing mechanism 4, the boom 5 is installed, which is characterized in that : The installation steps of the boom 5 are:

[0022] Step 1: threading the luffing wire rope 6;

[0023] Step 2: Install the boom 5 and the hoisting wire rope 7;

[0024] Step 3: Install the pulley block 8 of the jib tie rod.

[0025] The above step 1: first use the hoisting mechanism 9 and the auxiliary hemp rope to thread the luffing steel wire rope 6 with the pulley block 10 at the top of the tower and the pulley block 8 of the boom pulley, and then fix the pulley pulley 8 of the boom pulley on the top of the tower 3 on.

[0026] The above step 2: After the structural parts of the boom 5 are assembled, the boom tie rod 11 is assembled, and the pin shaft connection end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com