Multistage treatment system for oil sludge

A treatment system and oil sludge technology, applied in water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, pyrolysis treatment of sludge, etc., can solve the problems of undisclosed four-component separation technology and achieve environmental protection good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

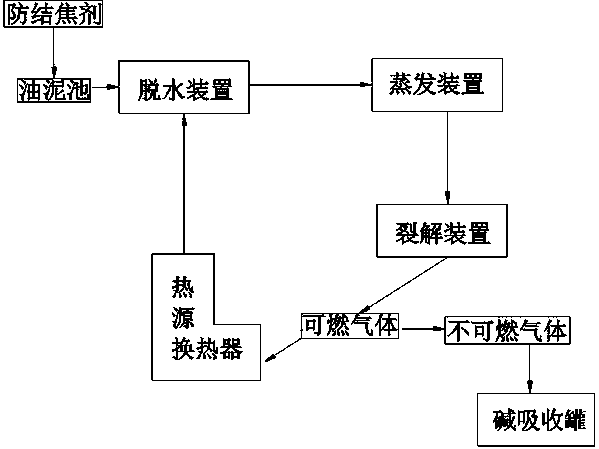

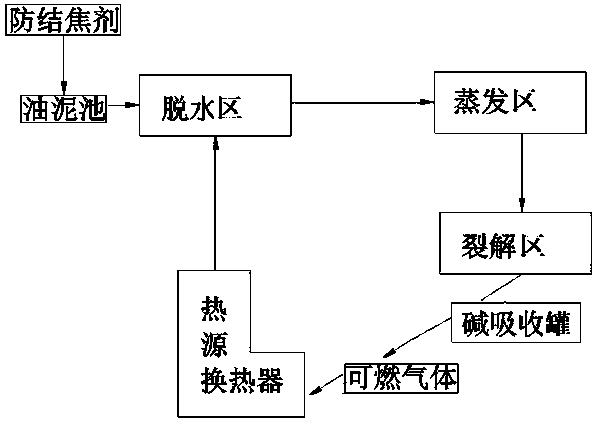

[0019] Such as figure 2 The shown multi-stage sludge treatment system has a dehydration zone, an evaporation zone, and a cracking zone arranged in order of position or time. A storage device for sludge is connected before the dehydration zone; the dehydration zone is equipped with Class I heating components, which can make The temperature of part of the sludge reaches 100-200°C.

[0020] An anti-coking agent is pre-added to the sludge. An evaporation zone is connected after the dehydration zone, and a cracking zone is set after the evaporation zone; the evaporation zone is equipped with Class II heating components, which can make the temperature of most of the sludge reach 200-300℃, and a large amount of light oil in the sludge is released; the cracking zone Equipped with Class III heating components, it can make the temperature of most of the sludge reach 300-400℃ or above. A large amount of heavy oil in the sludge produces a cracking reaction, and the heavy oil becomes small ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap