Vibration damping structure and washing machine

A vibration damping structure and washing machine technology, applied in the field of washing machines, can solve the problems of high cost, easy to generate noise, and difficult cleaning, and achieve the effects of small permanent deformation, strong resistance to impact loads, and convenient use and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments.

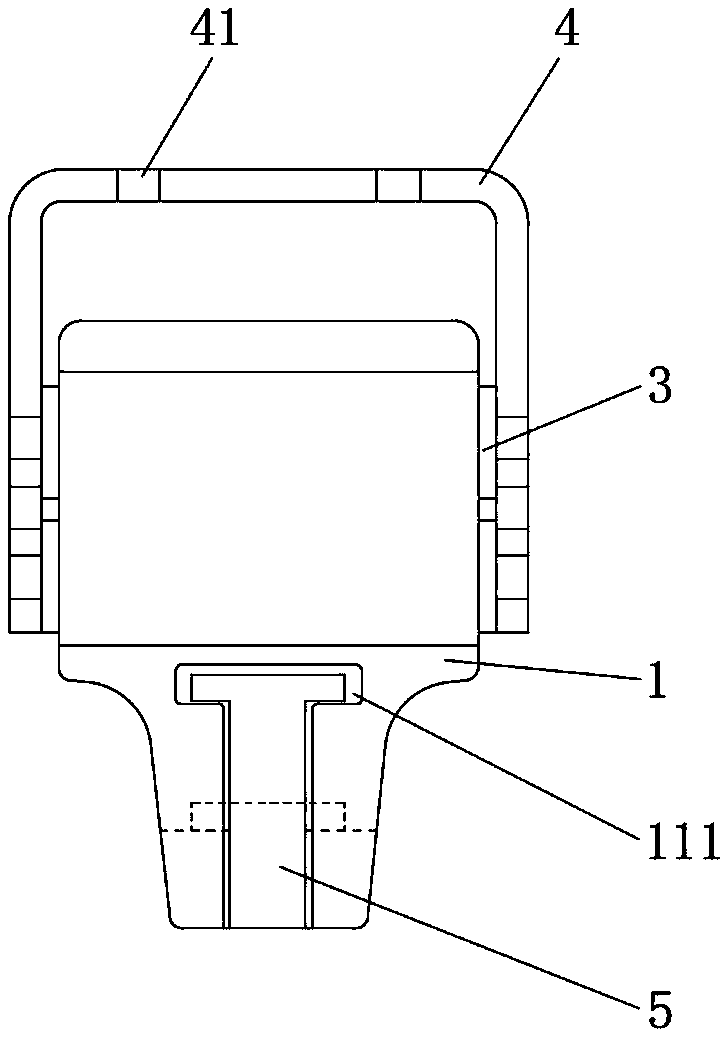

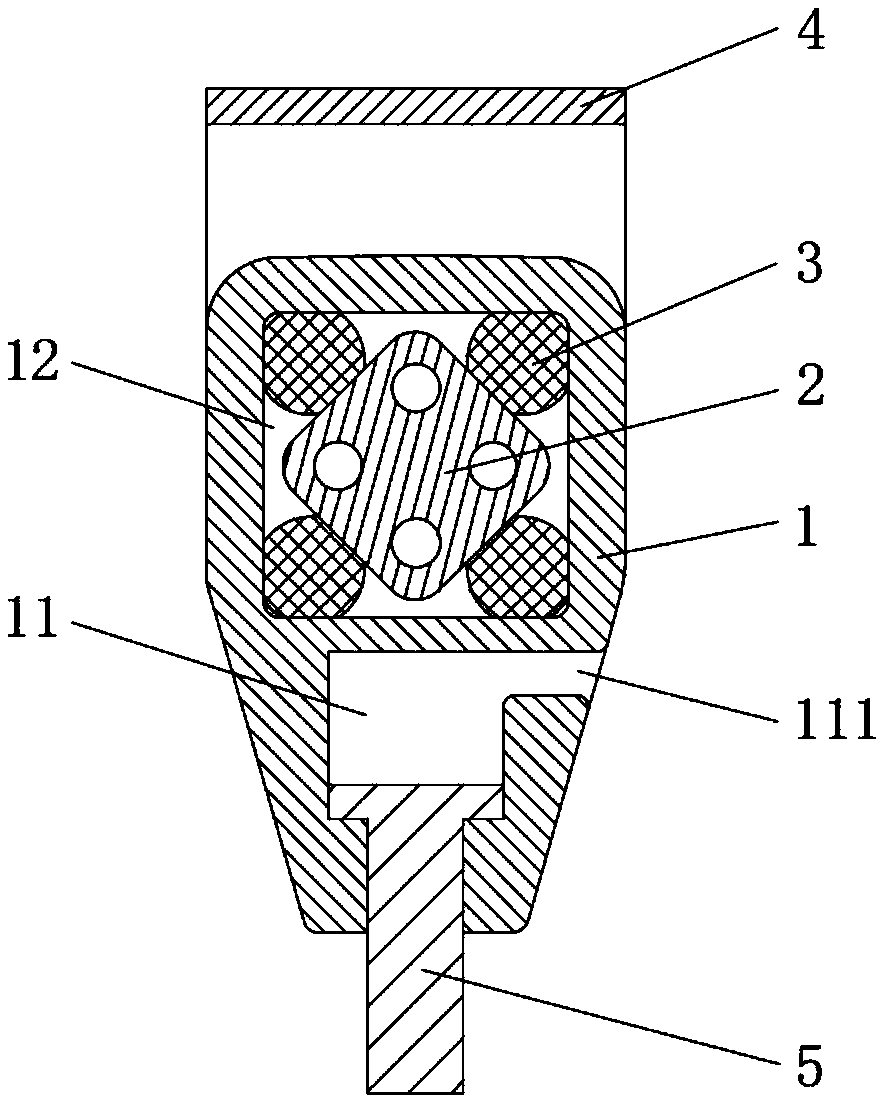

[0027] The invention provides a damping structure, such as figure 2 with image 3 As shown, the damping structure includes a shell 1, a liner 2, a damper 3 and a bracket 4, wherein:

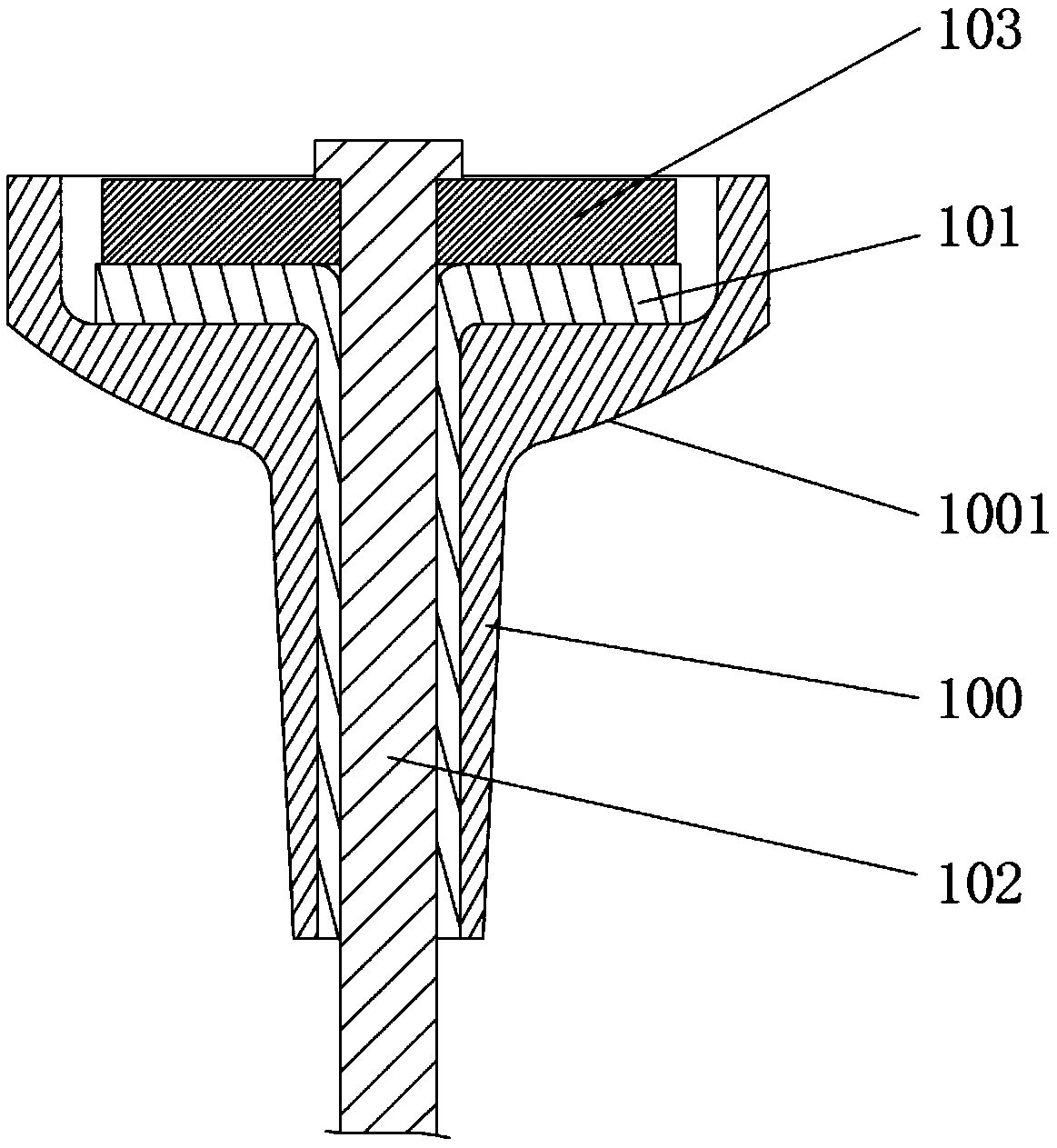

[0028] The casing 1 is provided with a first chamber 11 and a second chamber 12 which are independent of each other, wherein the first chamber 11 is located below the second chamber 12 and is used for placing the suspension rod 5 . Specifically, refer to Figure 2-4 One side of the above-mentioned first chamber 11 is provided with an opening 111, the opening 111 communicates with the space in the first chamber 11, and the shape of the opening 111 is the same as the cross-sectional shape of one end of the boom 5, and then can This end of the boom 5 is placed in the first chamber 11 through the opening 111 . In this embodiment...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap