Buckling beam quasi-zero rigidity vibration isolator

A quasi-zero stiffness, vibration isolator technology, applied in the direction of building components, earthquake resistance, building types, etc., can solve the problems of insufficient vibration isolation effect, achieve excellent low-frequency vibration isolation performance, small installation space, and good vibration isolation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments:

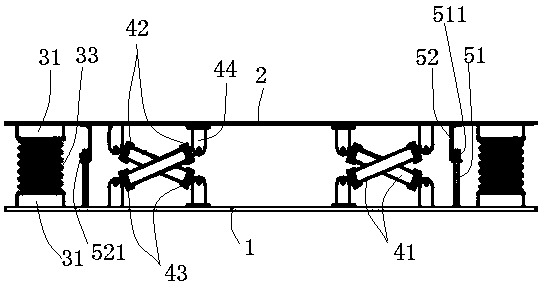

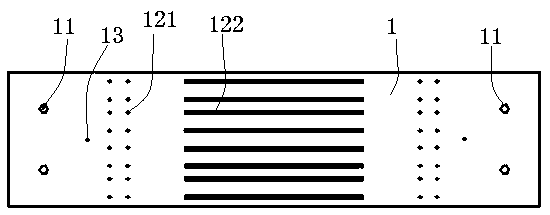

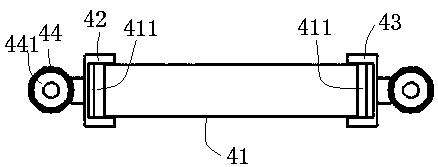

[0036] Such as Figure 1-4, a buckling beam quasi-zero stiffness vibration isolator, comprising a bottom plate 1 and a top plate 2 arranged parallel to the bottom plate 1, and a positive plate connecting the bottom plate 1 and the top plate 2 is arranged between the bottom plate 1 and the top plate 2 Stiffness mechanism and negative stiffness mechanism, the negative stiffness mechanism includes two elastic arms intersected, the elastic arms include a first base 42 and a second base 43, and the first base 42 and the second base 43 are provided with Two oppositely arranged buckling beams 41, the middle parts of the two buckling beams 41 are bent outwards, and the two ends of the buckling beams 41 are respectively connected to the first base 42 and the second base 43, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com