Control system, ignition system and ignition charging control method

A control system and ignition coil technology, applied in the direction of inductive energy storage devices, etc., can solve the problem that the charging time of the ignition coil is not accurate enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

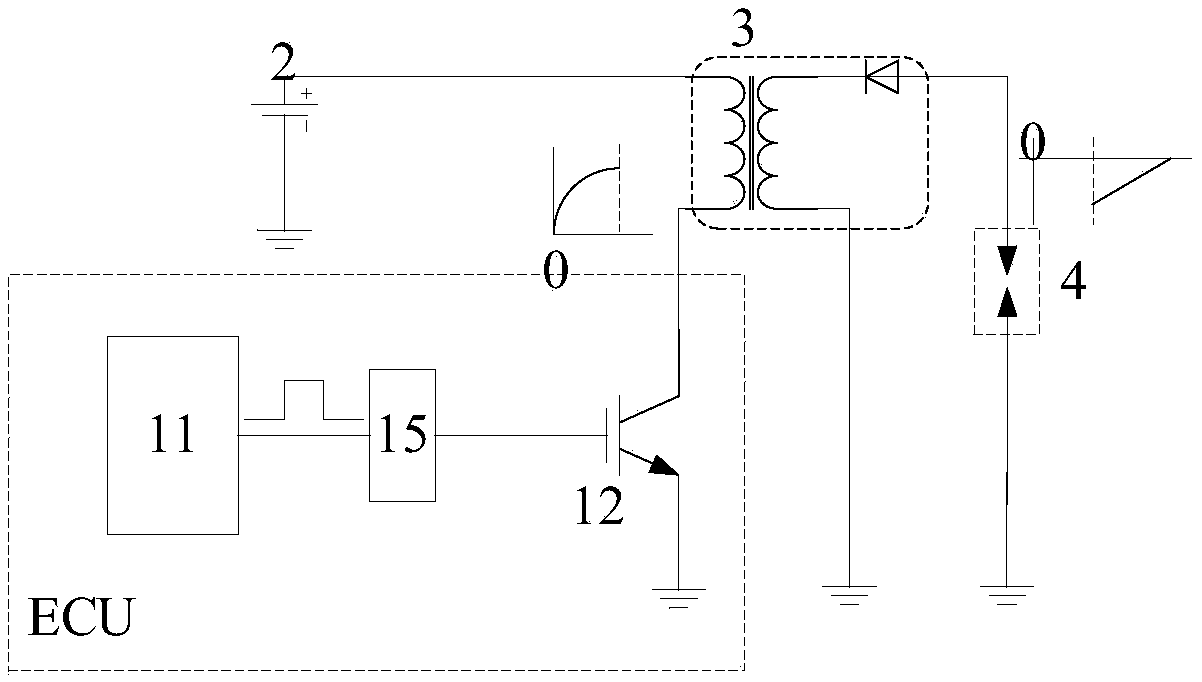

Embodiment 1

[0059] Please refer to image 3 The embodiment of the present invention provides a control system 1 for controlling the charging of the ignition coil. The control system 1 includes: a micro-control unit 11 connected in sequence to form a control loop, a driver stage switch 12, a detection resistor 13 and a comparison unit 14 . Optionally, the number of the control loops is n, and the n control loops include n the driver stage switches 12, and the n control loops share one micro control unit 11, and n is a natural number, For example, n can be 1, 2, 4, 6 or 8, etc., and the embodiment of the present invention is described for the case where n is equal to 1; the number of the detection resistor 13 and the number of the comparison unit 14 are equal and both are 1, one The detection resistor 13 and a comparison unit 14 form a detection circuit.

[0060] The comparison unit 14 is used to compare the voltage across the detection resistor 13 with a reference voltage Vref, and outpu...

Embodiment 2

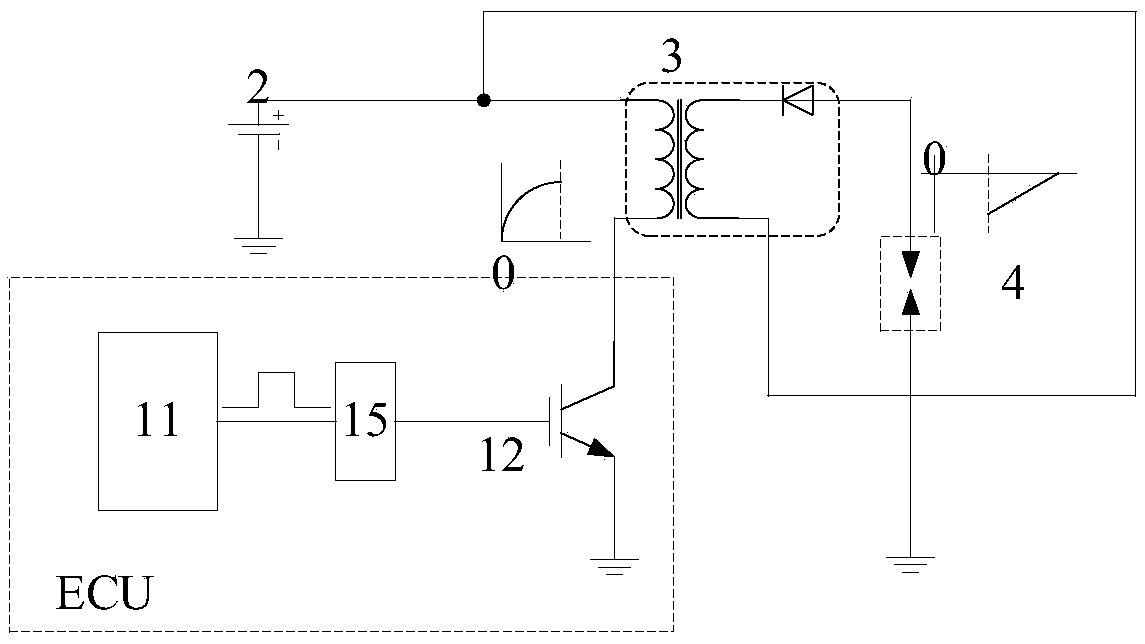

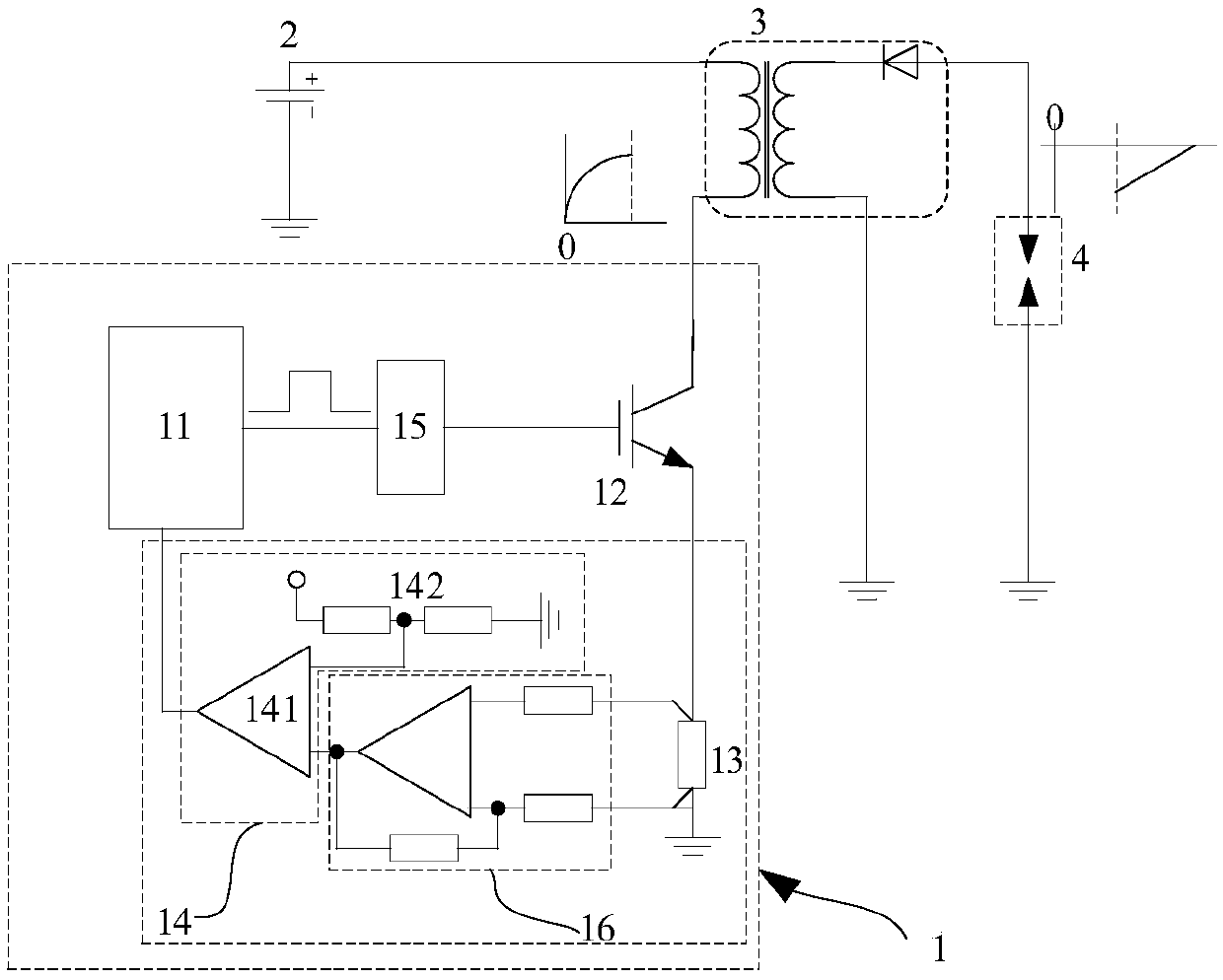

[0078] The difference from Embodiment 1 is that in the embodiment of the present invention, the control loop is connected to the primary stage of the ignition coil 3 through the detection resistor 13, such as Figure 5 As shown, the gate of the IGBT of the driving stage switch 12 is connected to the pre-driver circuit 15 , the collector is connected to one end of the detection resistor 13 , and the emitter is grounded.

[0079] In addition, compared with Embodiment 1, the control system 1 of the embodiment of the present invention must include a differential operational amplifier 16 to make a difference between the voltages across the detection resistor 13 and then amplify it before inputting it to the comparison unit 14. The input terminal of the above-mentioned differential operational amplifier 16 is added additional protection circuit (protection circuit Figure 5 not shown), in order to keep the control loop from being damaged under the condition of high voltage generated...

Embodiment 3

[0081] The difference from the second embodiment is that in the embodiment of the present invention, the primary of the ignition coil 3 is located between the detection resistor 13 in the control system 1 and the driving stage switch IGBT12, and the detection resistor 13 and the The connection end of the comparison unit 14 in the control system 1 is also connected to the battery 2, please refer to the specific connection relationship Figure 6 . Since the collector of the IGBT is directly connected to the primary of the ignition coil in the implementation of the present invention, there is no need to add an additional protection circuit, but it is necessary to introduce two additional wires from the outside of the control system to be connected to both ends of the detection resistor 13 for detection. The voltage across the sensing resistor 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com