Hydraulic stepless transmission

A continuously variable transmission, hydraulic technology, applied in the direction of fluid transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of easy breakage, engine or motor energy loss, conical wheel strain, etc., to achieve control Good performance, reliable action, high gear ratio effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

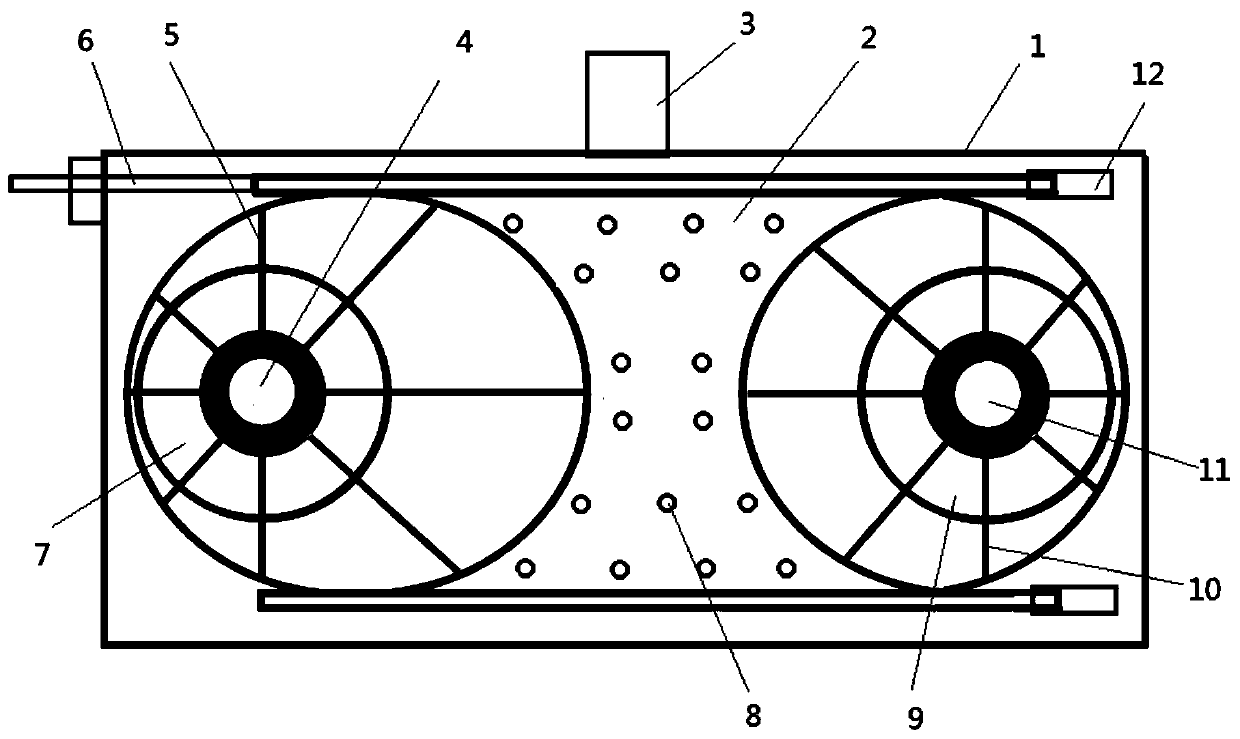

[0021] The present invention provides a hydraulic continuously variable transmission, which is characterized in that: the hydraulic continuously variable transmission includes a transmission housing 1, a transmission ratio adjustment slider 2, a liquid medium filling port 3, a driving shaft 4, and driving blades 5 , gear shift adjustment lever 6, driving wheel group 7, pipeline 8, driven wheel group 9, driven blade 10, driven shaft 11, slideway 12 at the end of the slider;

[0022] Wherein: the left side of the transmission housing 1 is equipped with a shifting adjustment lever 6 that can slide horizontally, the right side of the transmission housing 1 is provided with a slideway 12 at the end of the slider, and the driving wheel set 7 is installed inside the transmission housing 1 through the drive shaft 4 At the left end, the driven wheel set 9 is installed on the right end of the transmission housing 1 through the driven shaft 11; the driving wheel set 7 is equipped with a r...

Embodiment 2

[0034] The present invention provides a hydraulic continuously variable transmission, which is characterized in that: the hydraulic continuously variable transmission includes a transmission housing 1, a transmission ratio adjustment slider 2, a liquid medium filling port 3, a driving shaft 4, and driving blades 5 , gear shift adjustment lever 6, driving wheel group 7, pipeline 8, driven wheel group 9, driven blade 10, driven shaft 11, slideway 12 at the end of the slider;

[0035] Wherein: the left side of the transmission housing 1 is equipped with a shifting adjustment lever 6 that can slide horizontally, the right side of the transmission housing 1 is provided with a slideway 12 at the end of the slider, and the driving wheel set 7 is installed inside the transmission housing 1 through the drive shaft 4 At the left end, the driven wheel set 9 is installed on the right end of the transmission housing 1 through the driven shaft 11; the driving wheel set 7 is equipped with a r...

Embodiment 3

[0046] The present invention provides a hydraulic continuously variable transmission, which is characterized in that: the hydraulic continuously variable transmission includes a transmission housing 1, a transmission ratio adjustment slider 2, a liquid medium filling port 3, a driving shaft 4, and driving blades 5 , gear shift adjustment lever 6, driving wheel group 7, pipeline 8, driven wheel group 9, driven blade 10, driven shaft 11, slideway 12 at the end of the slider;

[0047]Wherein: the left side of the transmission housing 1 is equipped with a shifting adjustment lever 6 that can slide horizontally, the right side of the transmission housing 1 is provided with a slideway 12 at the end of the slider, and the driving wheel set 7 is installed inside the transmission housing 1 through the drive shaft 4 At the left end, the driven wheel set 9 is installed on the right end of the transmission housing 1 through the driven shaft 11; the driving wheel set 7 is equipped with a ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com