Self-energy-taking thyristor valve

A thyristor valve and self-energy harvesting technology, which is applied in the direction of output power conversion devices, electrical components, starter parts, etc., can solve problems such as expanding accidents and increasing the production cost of thyristor valves, so as to facilitate increase and decrease and meet insulation requirements. and the effect of anti-interference requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

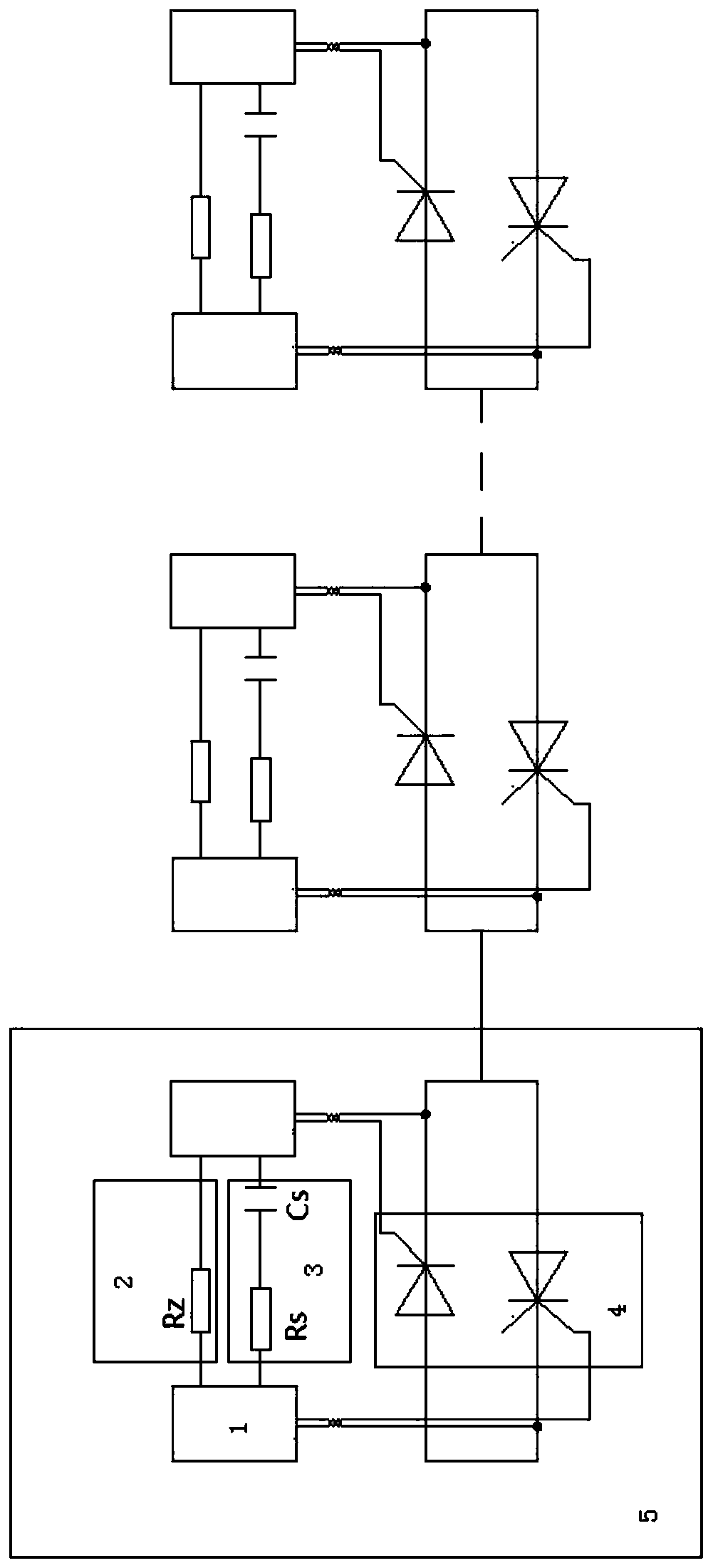

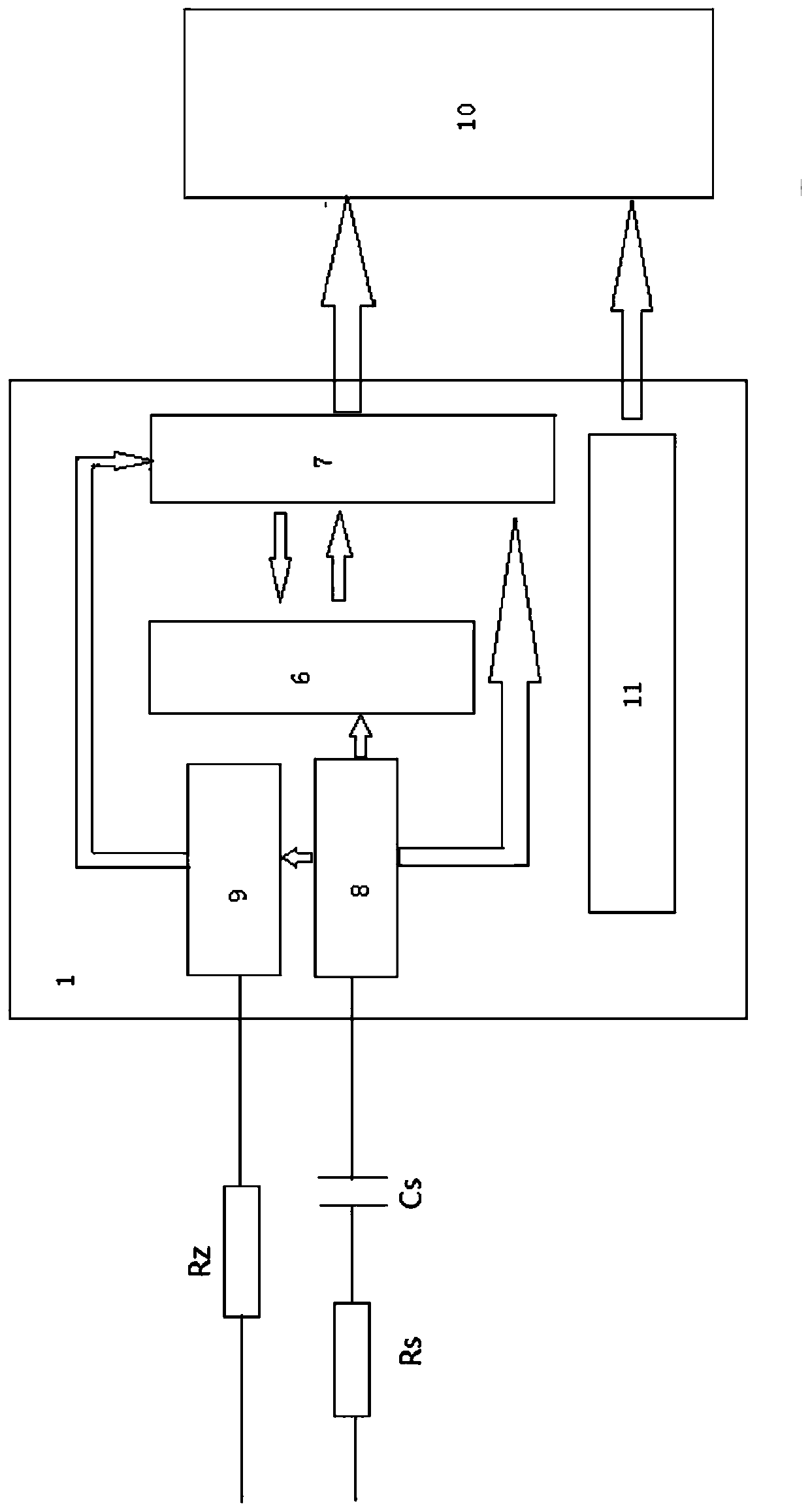

[0021] This embodiment is a kind of self-energy thyristor valve, the thyristor valve and the upper computer are only connected by optical fiber, such as figure 1 As shown, the thyristor valve is composed of at least one basic unit 5 connected in series. The basic unit includes two trigger plates 1, one left and one right, an AC voltage equalizing circuit 3, a DC voltage equalizing circuit 2 and a thyristor group 4. The AC voltage equalizing circuit is connected to the left The trigger board and the right trigger board, the DC equalizing circuit connects the left trigger board and the right trigger board, the thyristor group includes two thyristors connected in anti-parallel, the left trigger board is respectively connected with the gate and cathode of the thyristors located below, and the right trigger board They are respectively connected to the gate and anode of the thyristor located above, and the thyristor groups between two adjacent basic units are connected in series. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com