Automatic liquid flow rate stabilizer based on jet cavitation

An automatic and stable liquid flow technology, applied in jet pumps, machines/engines, non-displacement pumps, etc., can solve the problems of long fluctuation time of flow set value, low flow stability accuracy, complex device structure, etc., to achieve Improve the ability to adapt to the medium, improve the accuracy of flow control, and improve the effect of controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

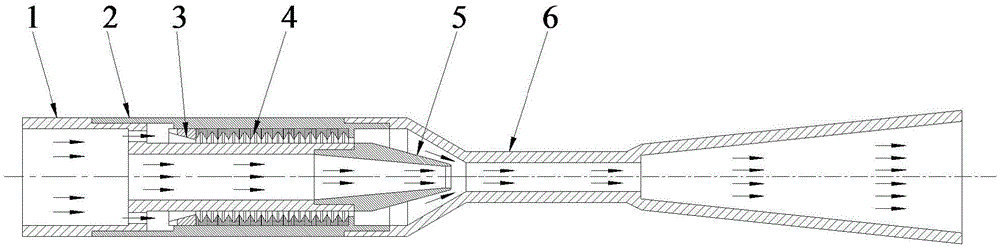

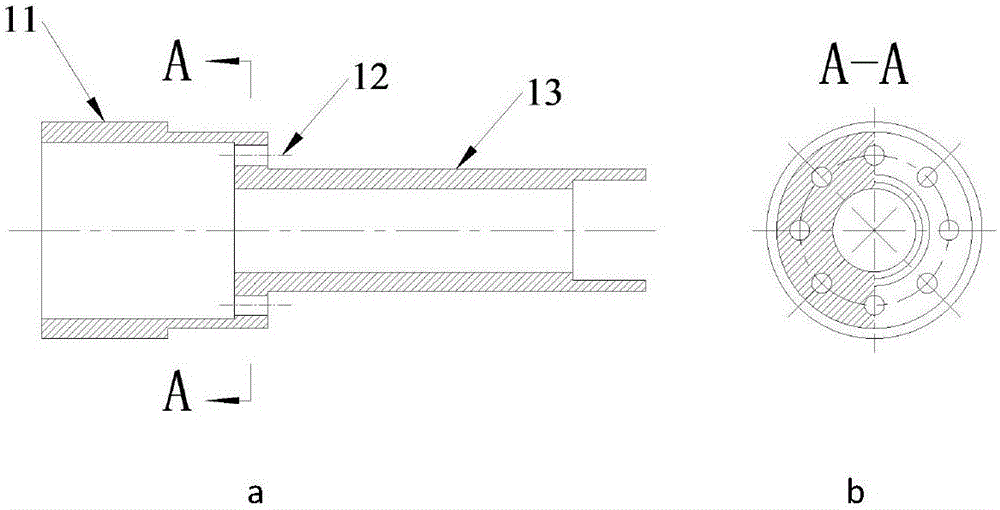

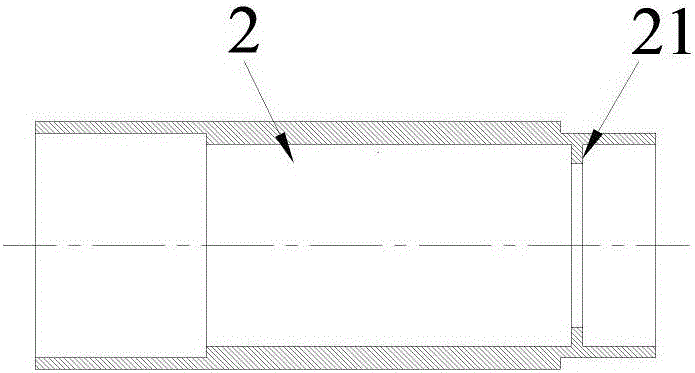

[0030] An automatic liquid flow stabilization device based on jet cavitation, comprising a supply pipe 1, a tubular suction chamber 2 and a cavitation chamber 6 connected coaxially in sequence along the direction of water flow; The larger-diameter total incoming flow pipe 11 and the smaller-diameter nozzle connecting pipe 13; the outlet end of the nozzle connecting pipe 13 is provided with a nozzle 5; the nozzle connecting pipe 13 is located in the suction chamber 2; the cavitation The cavity 6 includes a constriction tube 61, a throat 62 and a diffuser tube 63 connected together along the direction of water flow; one end of the suction chamber 2 is connected to the main flow pipe 11 through threads, and the other end is connected to the constriction tube 61 through threads; A number of suction chamber supply holes 12 communicated with the suction chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com