Vibration Decoupling System

A motion and actuator technology, applied in vibration suppression adjustment, rotation vibration suppression, agricultural machinery, etc., can solve problems such as damage to actuators and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

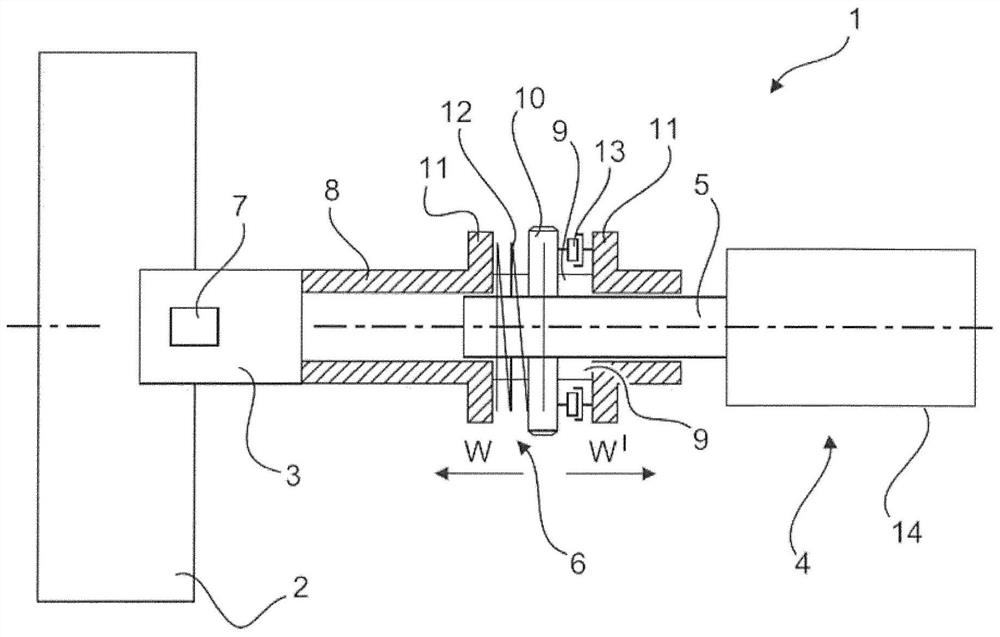

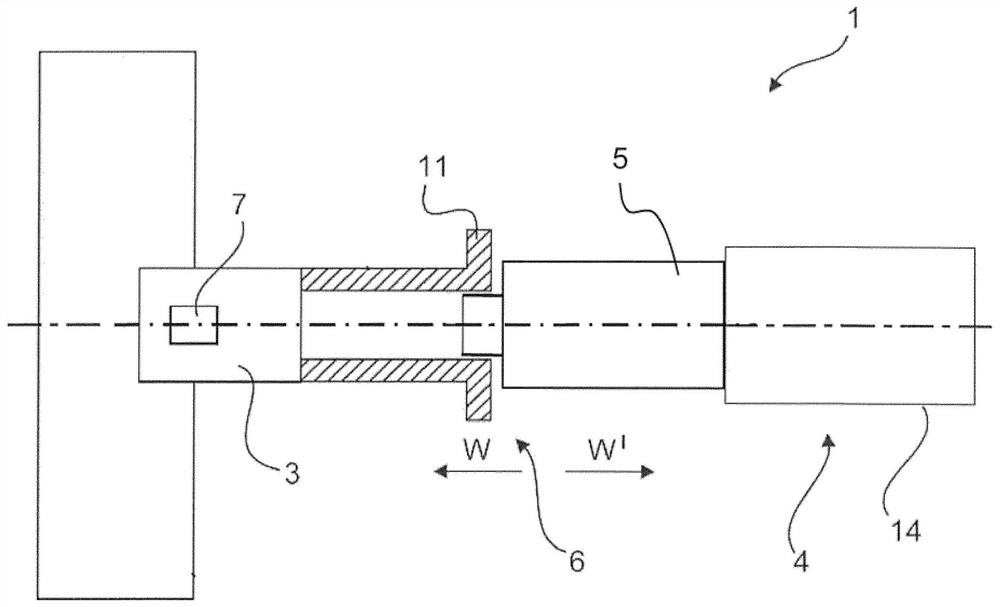

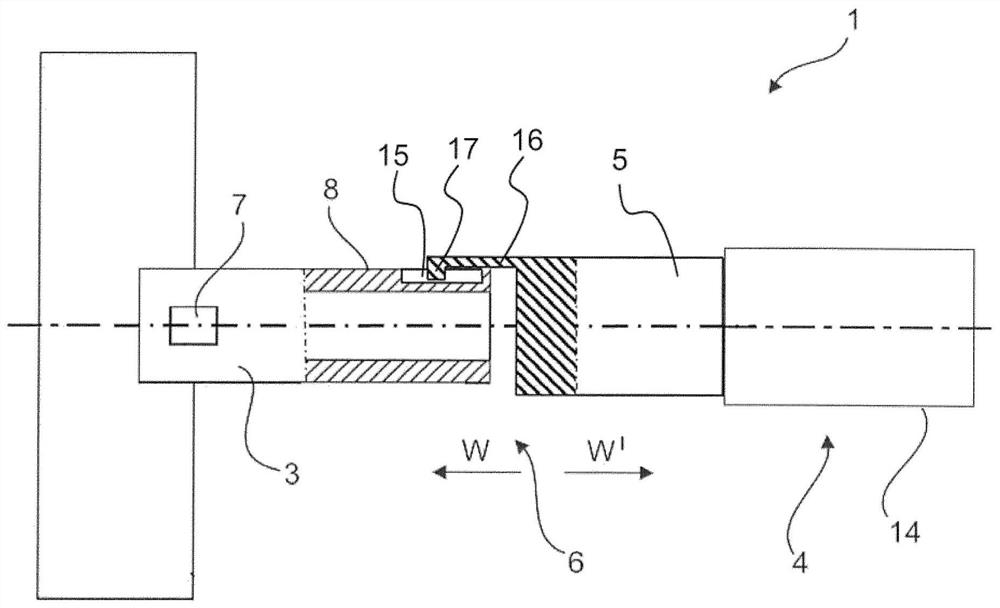

[0025] exist figure 1 A clutch system for a vehicle drive train with a vibration decoupling system 1 according to the invention is schematically shown in .

[0026] The clutch system has a clutch 1 for disconnecting and connecting the power flow in the drive train. Furthermore, a disengaging mechanism for the clutch 2 is provided as adjusting element 3 in the clutch system, which is used for engaging and disengaging said clutch 2 . Furthermore, the clutch system has a clutch actuator as actuator 4 .

[0027] The actuating device 4 is provided with an active element 5 . The active element 5 is, for example, a ball screw of an electrical linear unit or a piston rod of a hydraulic or pneumatic cylinder and carries out a first active movement for manipulating the adjusting element 3 in a predetermined active direction W and in the opposite direction. A second acting movement in direction W' of said acting direction W.

[0028] Furthermore, the vibration decoupling system 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com