Cutting tool

A cutting tool, cutting insert technology, applied in cutting inserts, milling cutting inserts, tools for lathes, etc., can solve the problem of increased wear of screw heads, and achieve the effects of easy processing, improved stability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

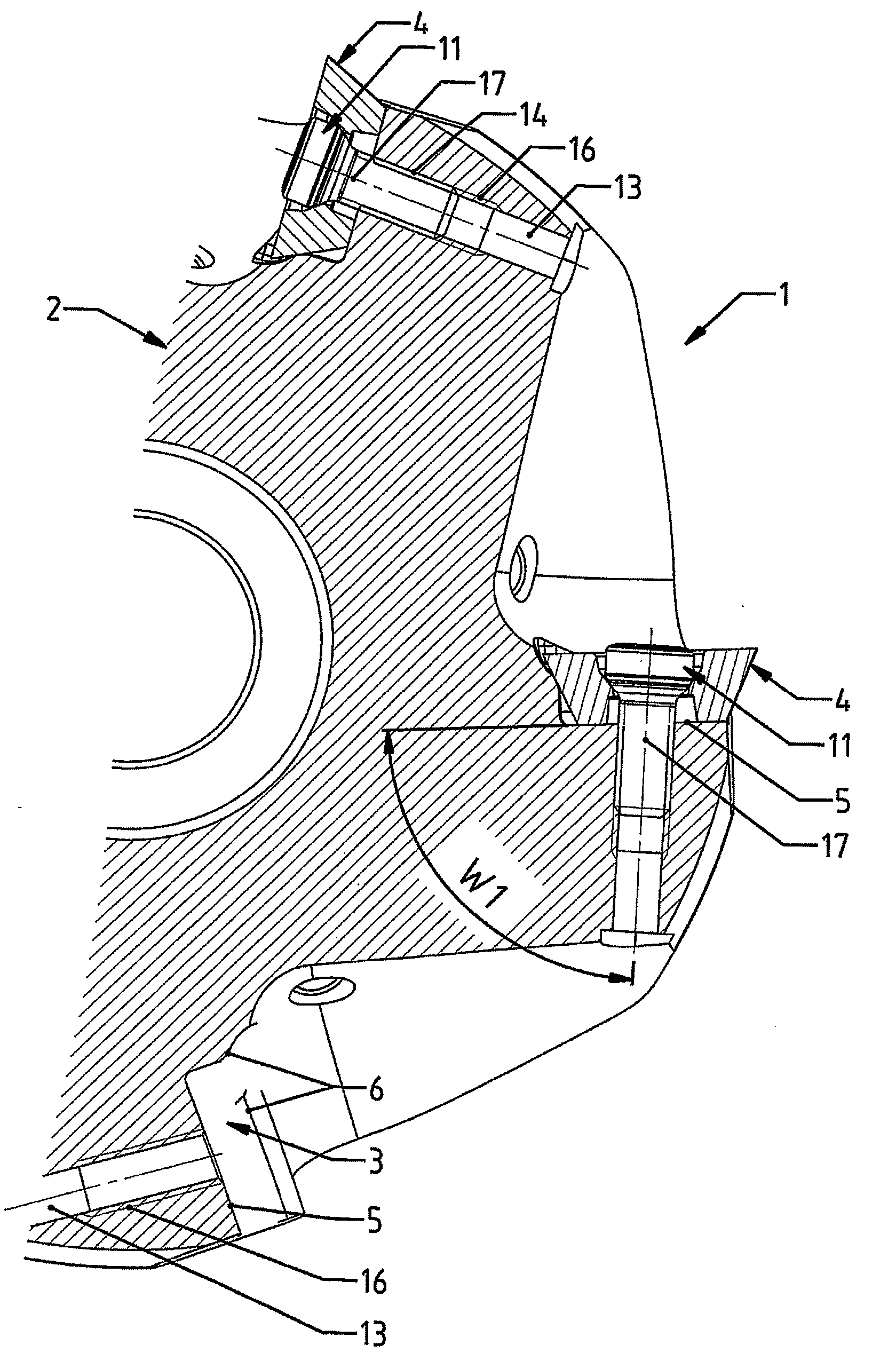

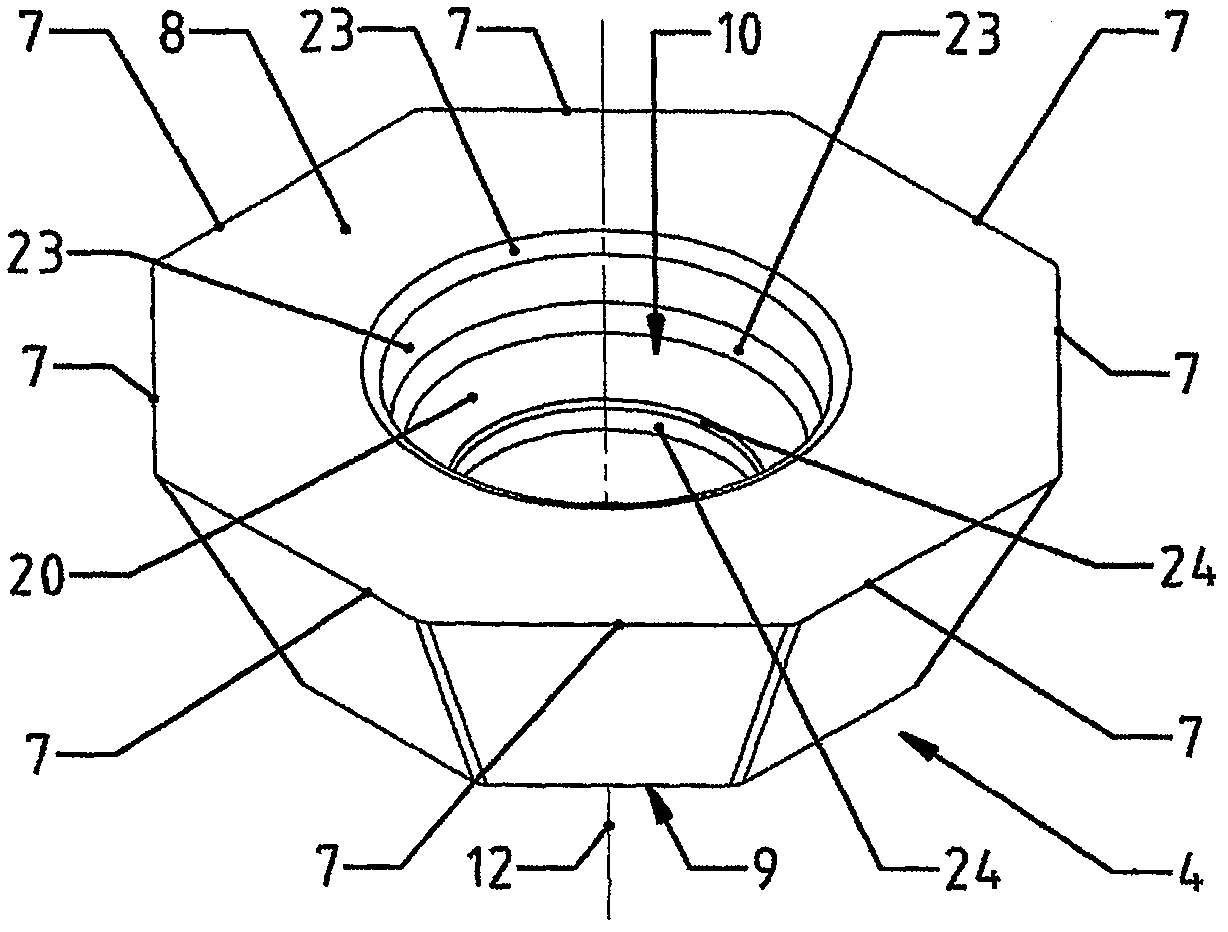

[0030] figure 1 The cutting tool 1 shown is a tool for milling which comprises a tool body 2 . The head of the tool body 2 has a plurality of mounting points 3 for fastening exchangeable cutting inserts 4 . The mounting position 3 has a bottom surface 5 and a lateral stop surface 6 for positioning the cutting insert 4 . The cutting insert 4 has an octagonal cross-section with corresponding eight cutting faces 7 ( figure 2 ), whereby the cutting insert 4 is multi-purposed by means of the respective active cutting face 7 . The cutting insert 4 is pierced by a central through-hole 10 from a first upper surface 8 (generally the cutting face region) to a support surface 9 situated opposite the upper surface and facing the mounting position of the bottom surface 5 . The support surface 9 rests on the bottom surface 5 in the assembled position of the cutting insert 4 .

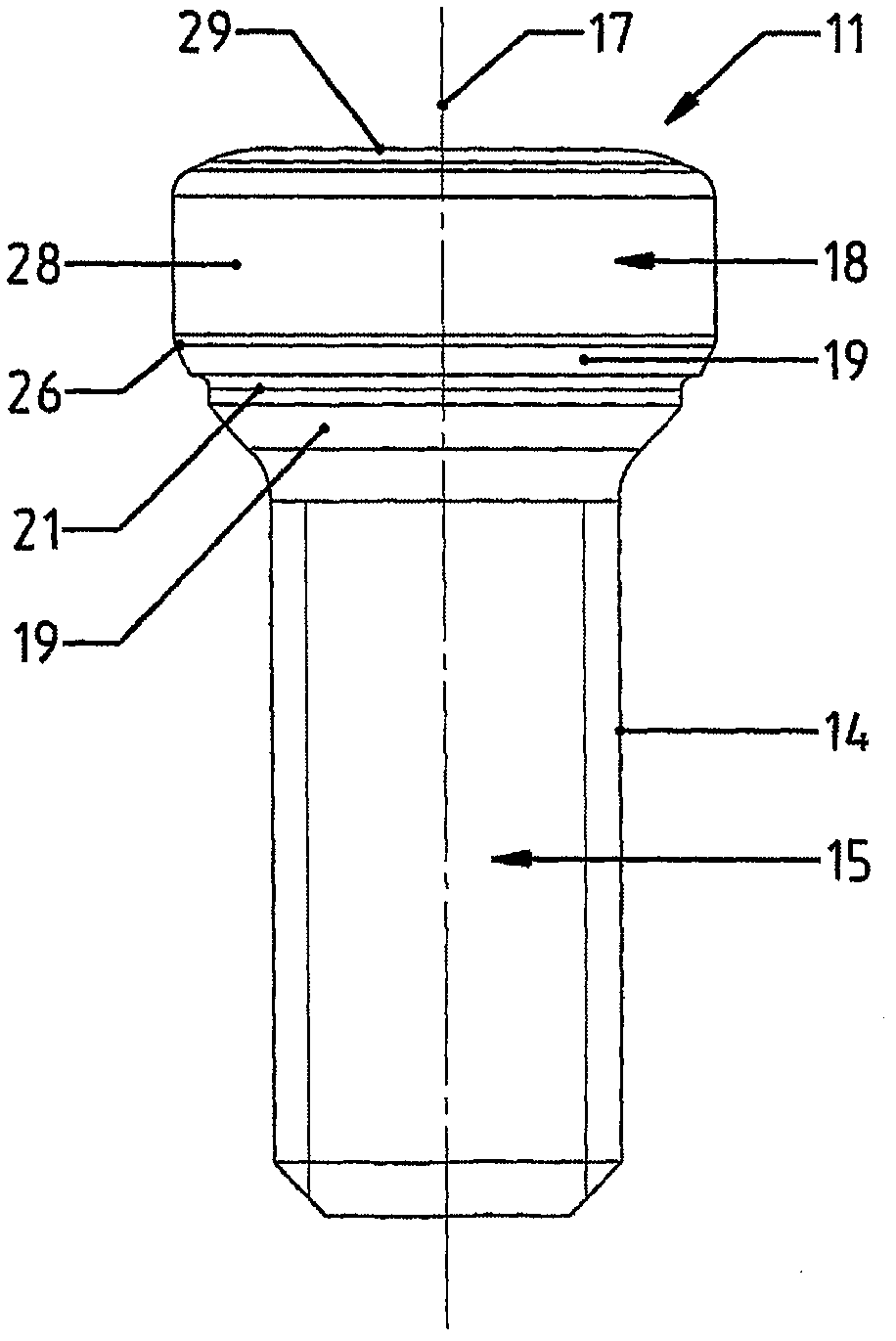

[0031] Each cutting insert 4 is fixed on the mounting location 3 by means of a locking pin, which is formed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com