Vacuum coated component and production method thereof

A technology of vacuum coating and manufacturing method, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the limitation of competitiveness in the field of decorative coating, plastic shell and painted shell cannot show metallic texture, vacuum coating The layer color is not rich enough, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

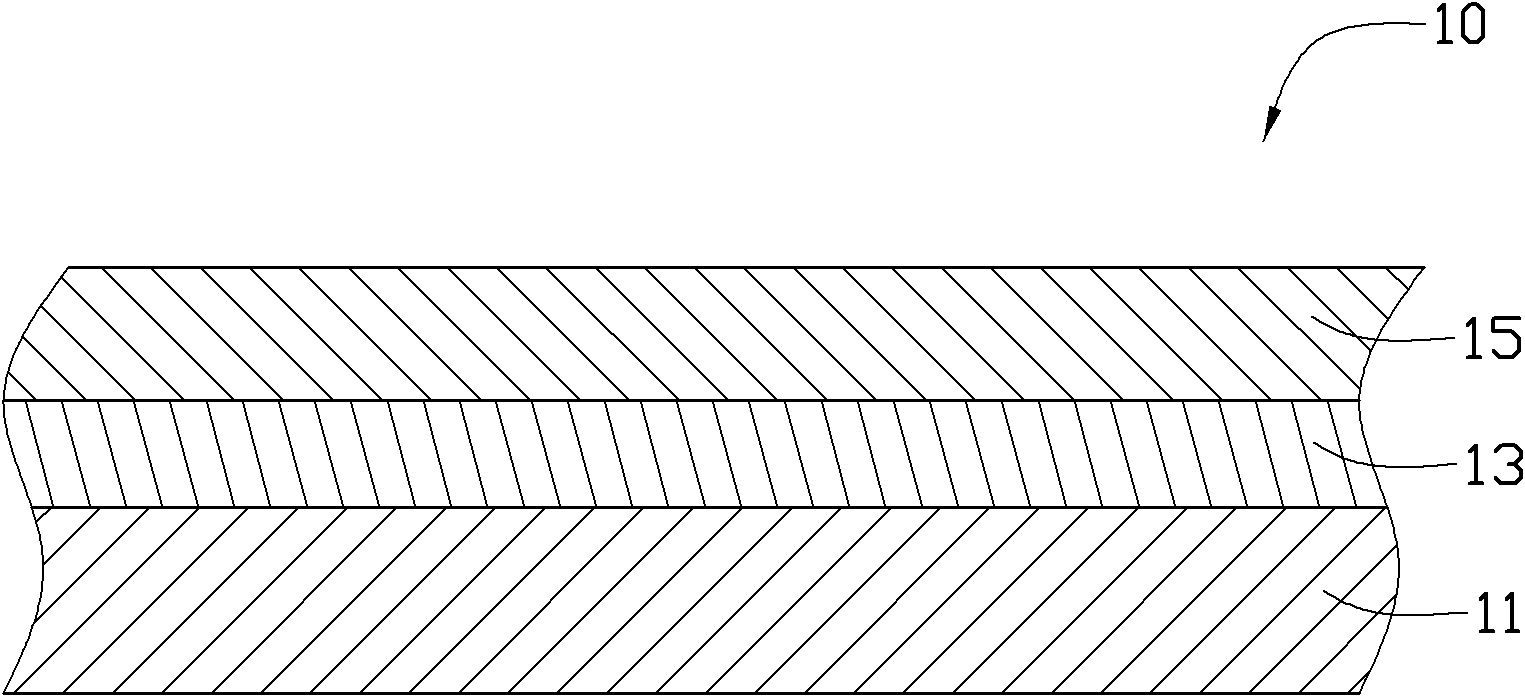

[0013] see figure 1 , the vacuum coating member 10 of a preferred embodiment of the present invention can be a casing of a mobile phone. The vacuum coating member 10 includes a base 11 , a base layer 13 and a color layer 15 . The base layer 13 is disposed on the surface of the base body 11 , and the color layer 15 is disposed on the surface of the base layer 13 .

[0014] The substrate 11 may be metal material or non-metallic material such as glass or plastic.

[0015] The substrate layer 13 is formed on the surface of the substrate 11 by magnetron sputtering. The substrate layer 13 is a titanium layer with a thickness of 50-100 nm. The color of the base layer 13 is a light tone that does not affect the color of the color layer, such as silver, white, off-white and other light tones.

[0016] The color layer 15 is a Ti-O-N film, which is formed by magnetron sputtering. The color layer 15 has a thickness of 200-350 nm. The color layer 15 visually presents a sky blue color...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com