Astragalus membranaceus granule granulating device

A technology of granules and astragalus, which is applied in the field of astragalus granules granulation device, can solve the problems of poor granulation effect of astragalus granules, easy dispersion of astragalus granules, lack of air-drying components, etc., so as to improve granulation effect, enhance hardness, and facilitate heat dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

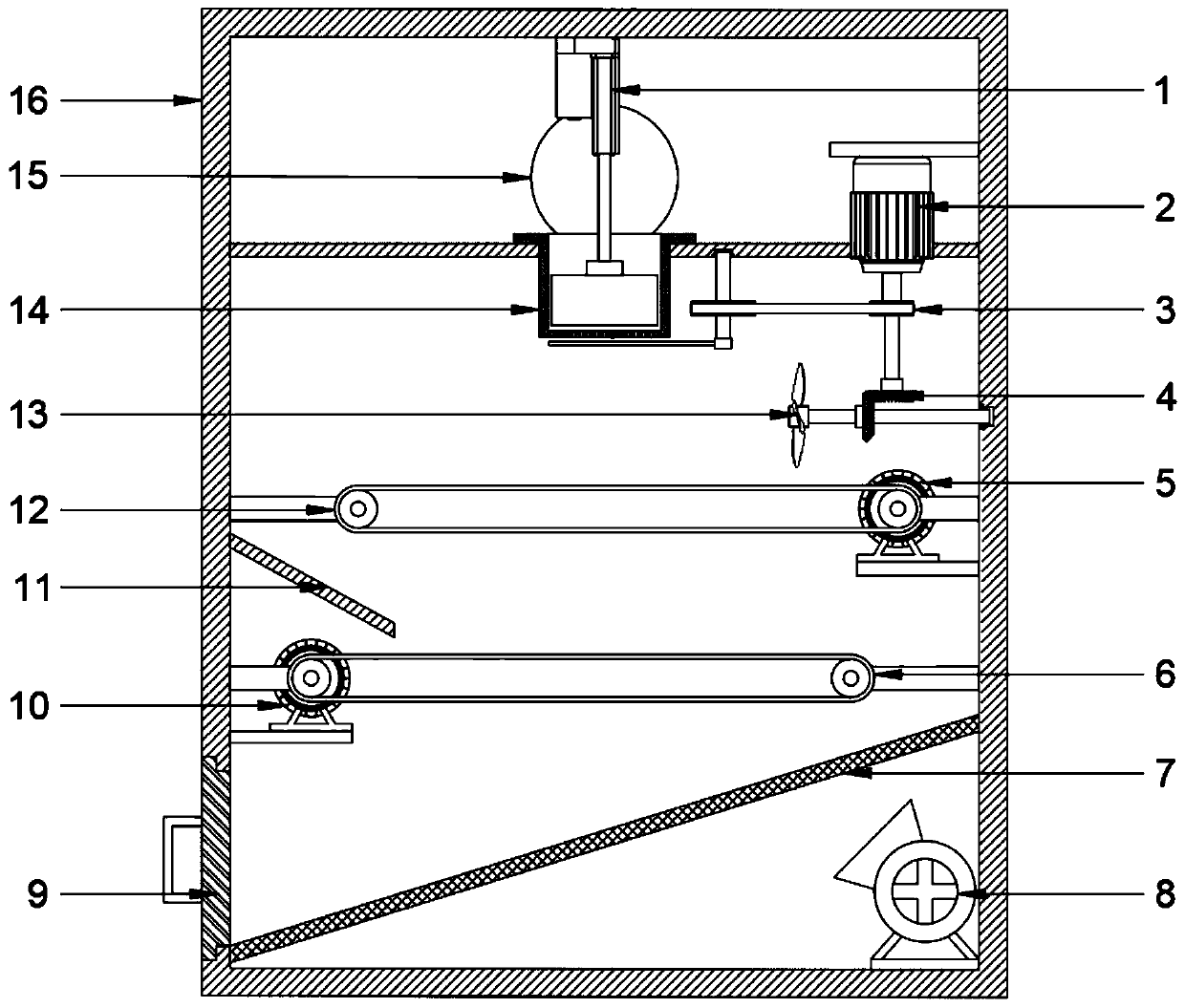

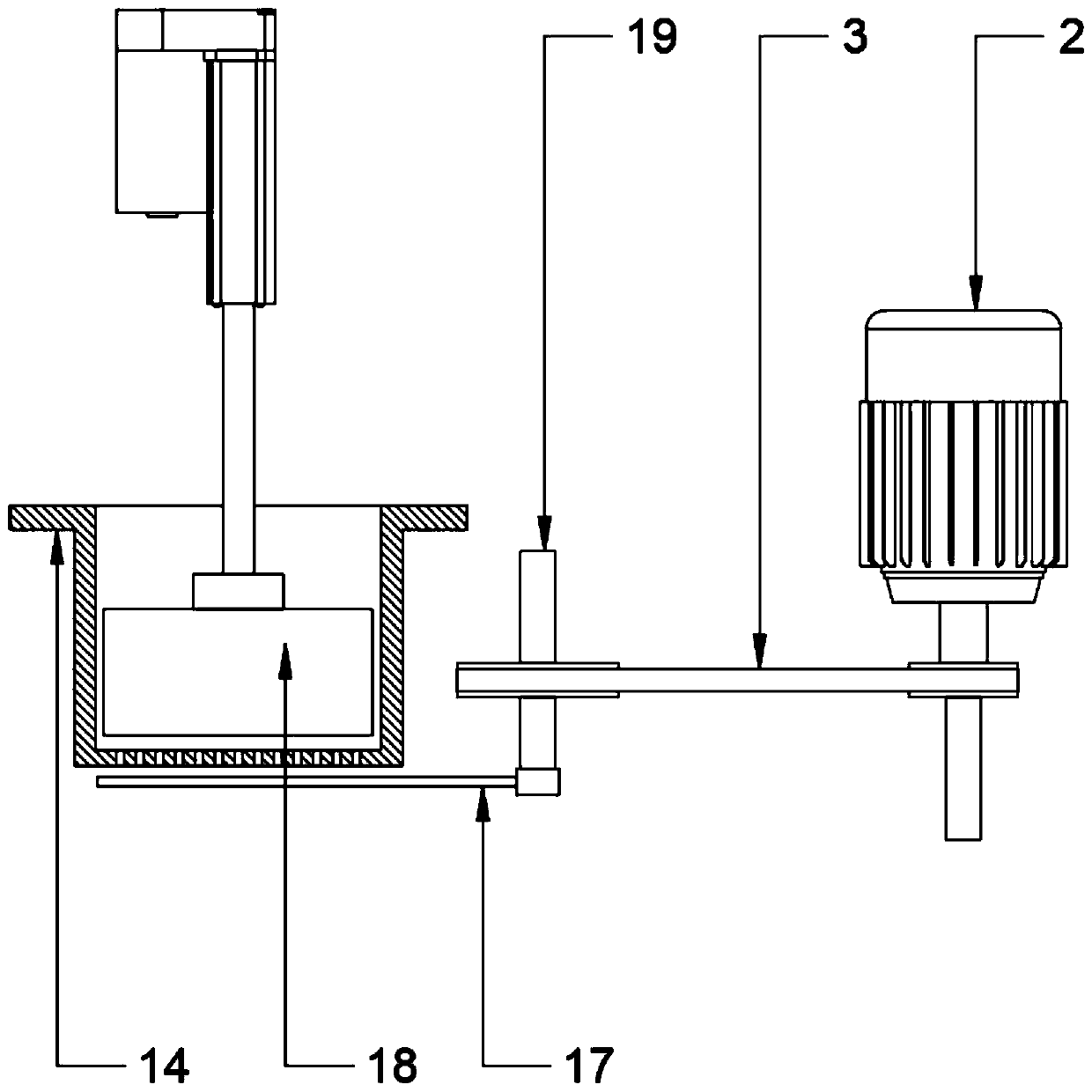

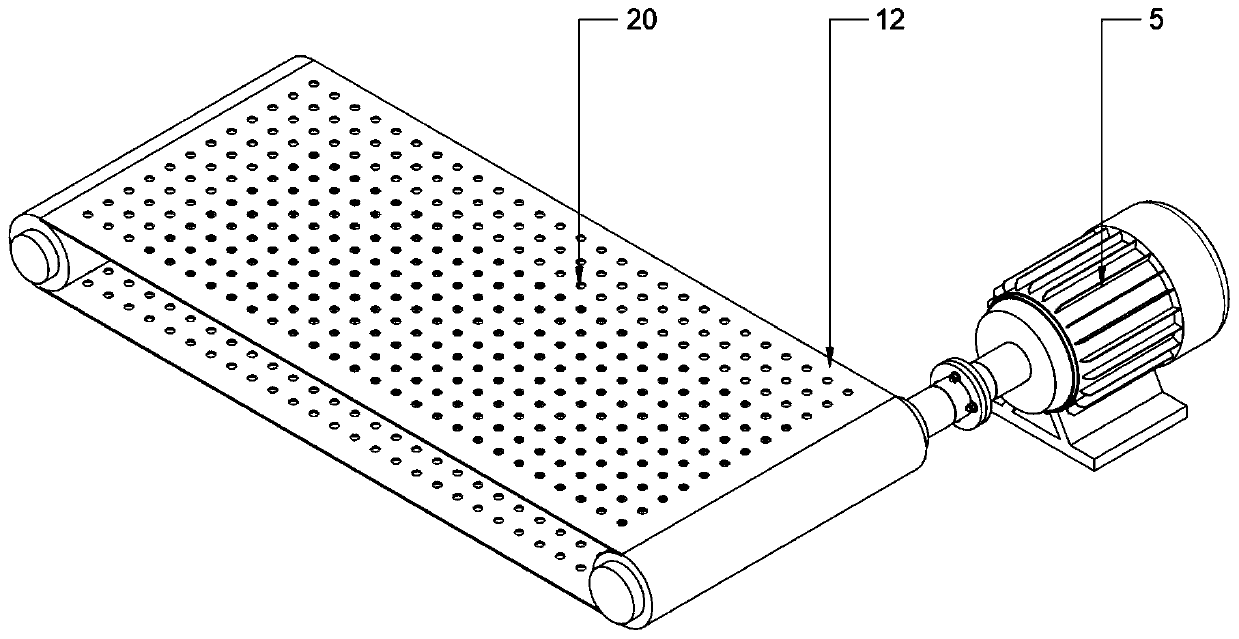

Embodiment 1

[0023] see Figure 1~4 , in the embodiment of the present invention, a granulation device for astragalus granules includes a box body 16 and a granulation assembly and an air-drying assembly arranged inside the box body 16, and the granulation assembly is arranged above the air-drying assembly to facilitate direct Air-drying is convenient for subsequent use and storage. The granulation assembly includes a granulation pot 14, a granulation blade 17 and a granulation hammer 18. The granulation pot 14 is movably clamped on the support rod inside the box body 16 and There are several sets of granulation holes 21 at the bottom, one end of the granulation hammer 18 is set inside the granulation pot 14 and the other end is set in linkage with the drive assembly that drives the granulation hammer 18 to reciprocate and slide, and the granulation blade 17 rotates It is arranged under the granulation pot 14 and is provided with a driving assembly in linkage at one end away from the granu...

Embodiment 2

[0030] see Figure 4 , in the embodiment of the present invention, a granulation device for astragalus granules, in order to enhance the practicability of the device, on the basis of embodiment 1, a flange is provided on the outer edge of the upper port of the granulation pot 14, which is convenient for clamping on the The support rod inside the box body 16 can be disassembled at any time. The granulation hole 21 has various sizes and specifications, and the granulation pot 14 with different apertures can be replaced according to the actual granulation thickness requirements; the first motor 2 The rotating speed is adjustable. By adjusting the rotating speed of the first motor 2, the length of the granules can also be adjusted. Cooperating with the granulating holes 21 of different apertures, it can meet various granulating needs and has strong practicability.

[0031] The working principle of the present invention is:

[0032]When working, according to the granulation requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com