Footlet as well as method for manufacturing such a footlet

A technology of boat socks and socks, applied in socks, pantyhose, clothing, etc., to achieve the effect of low process quantity and preventing pressure marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

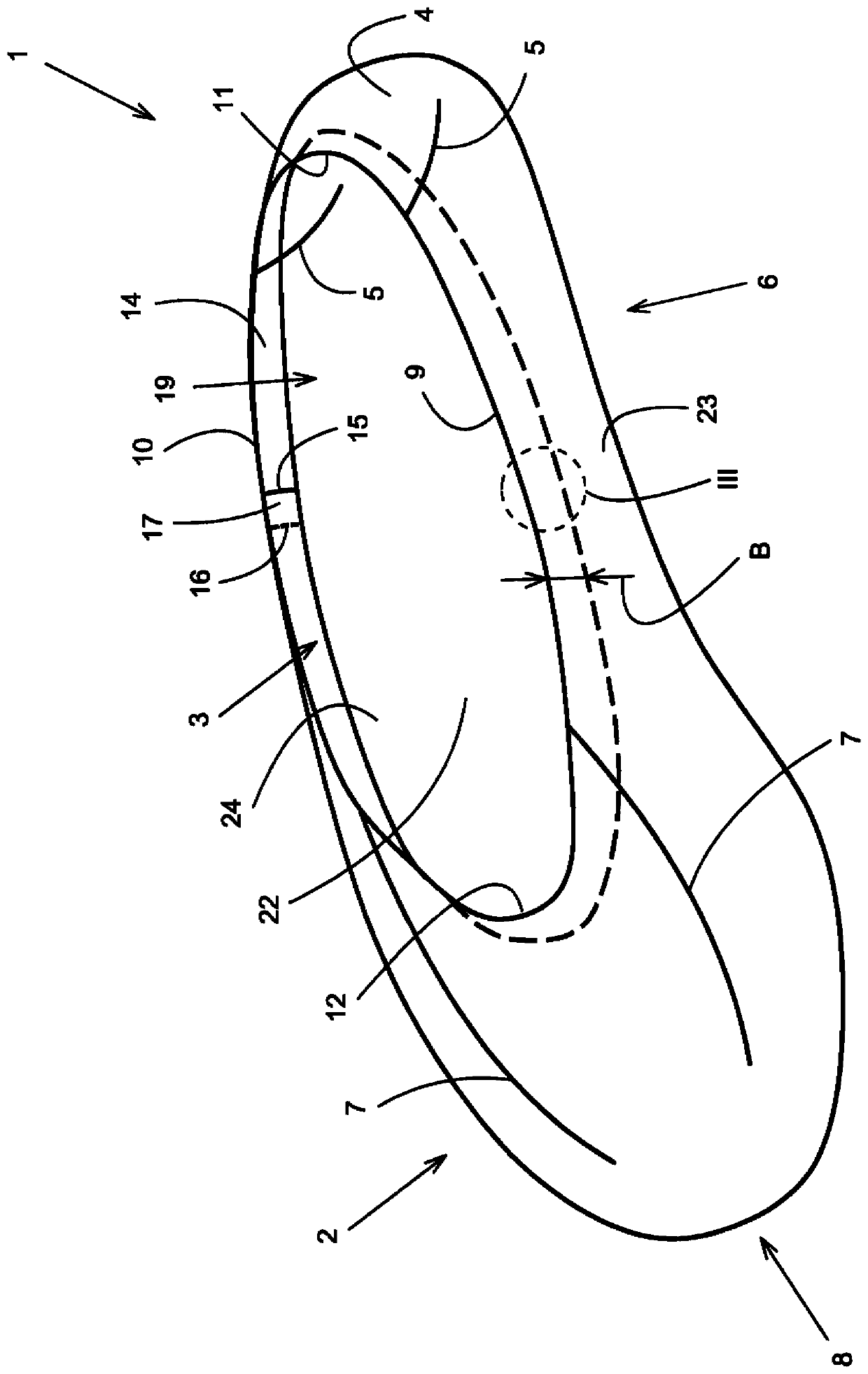

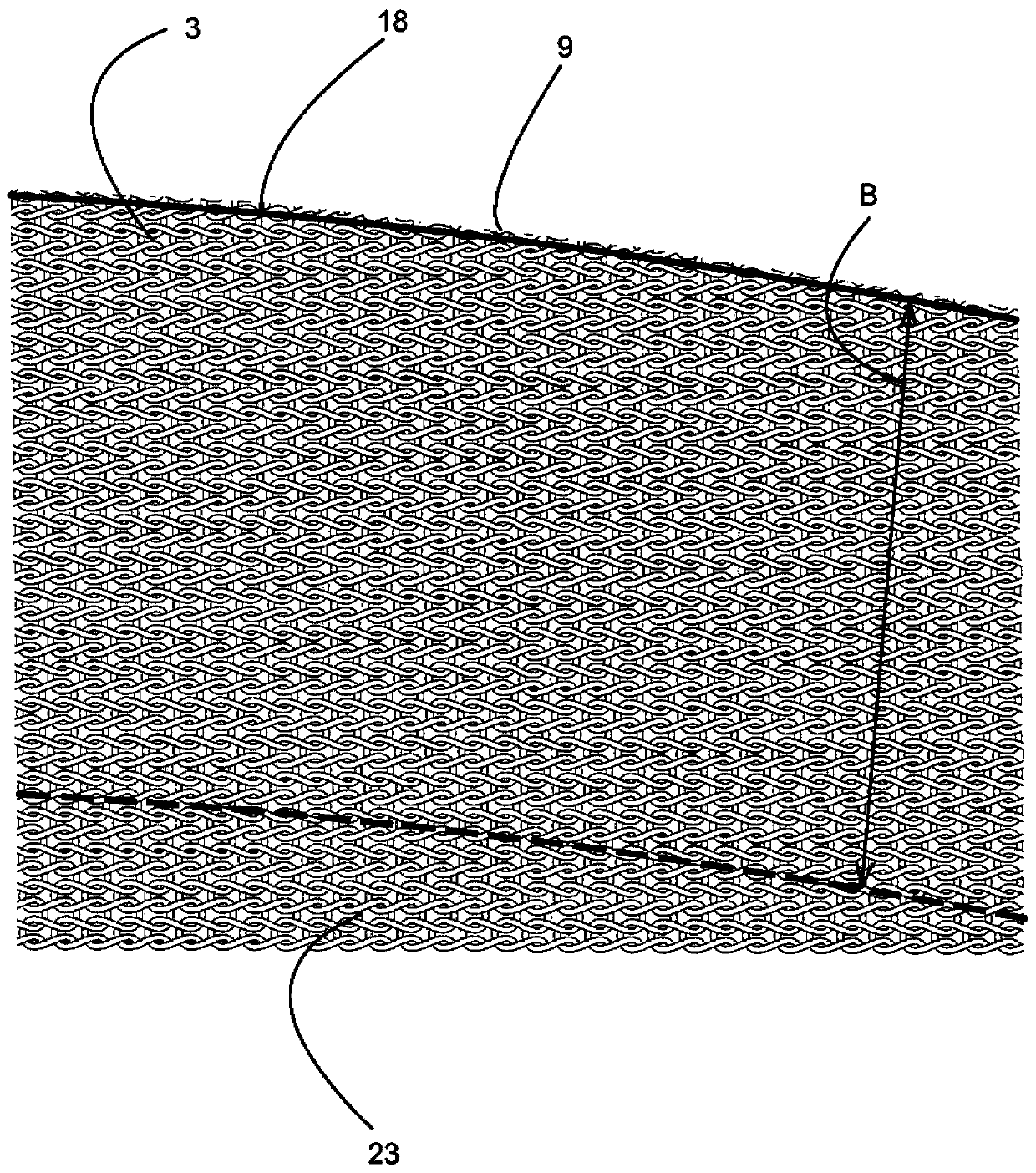

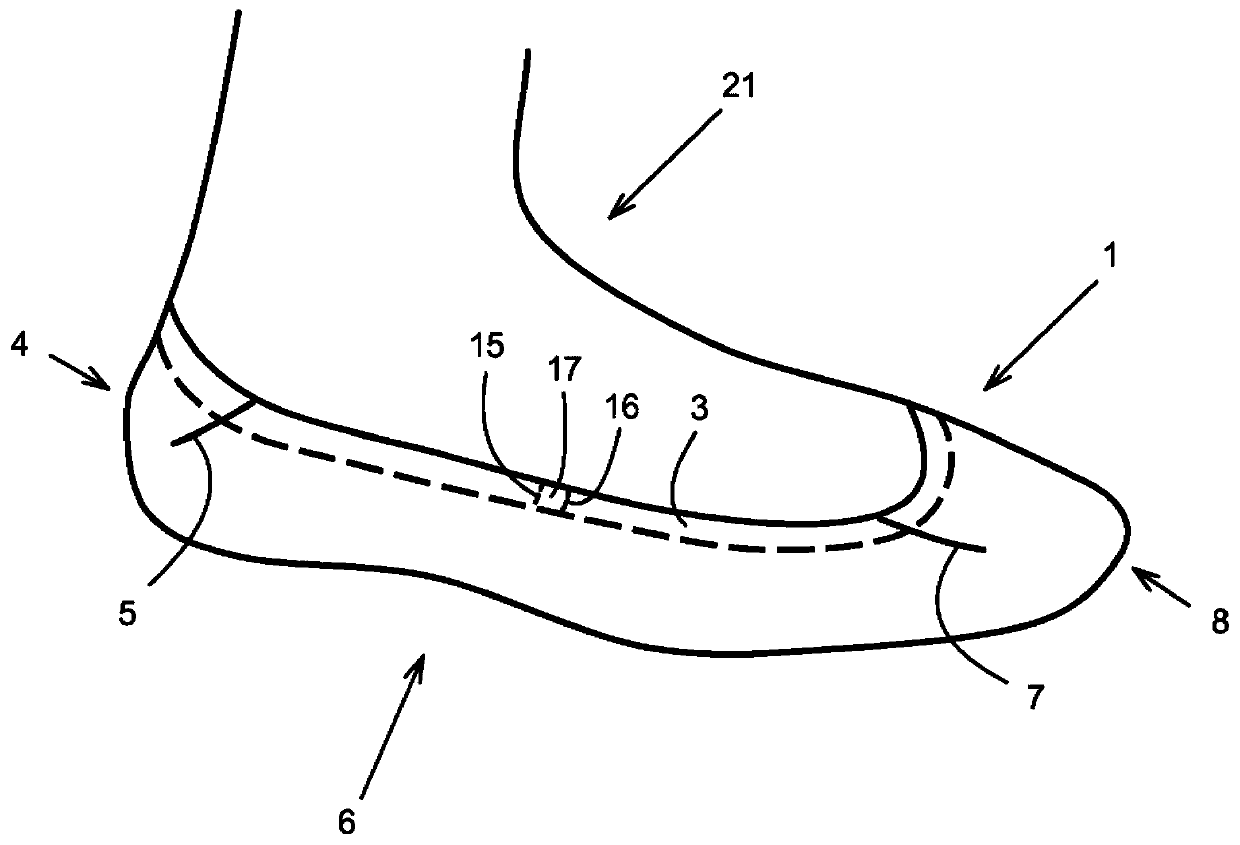

[0052] figure 1 Shown is a boat sock 1 according to the invention provided with a knitted part 2 and an elastic band 3 . The braided portion 2 is manufactured by reciprocating weaving only by reciprocating weaving. Thereby, a seamless knitted portion 2 is obtained. The seamless knit part 2 is provided with a heel part 4 , a middle part 6 connected to the heel part 4 by a knit forming thread 5 and a toe part 8 connected to the middle part 6 by a knit forming thread 7 . The knitted portion 2 of a desired shape can be obtained by increasing and decreasing the number of needles during reciprocating knitting. The middle part 6 comprises side parts 9 , 10 extending on both sides between the heel part 4 and the toe part 6 . The sides 9 , 10 are attached to each other by the sides 11 , 12 of the heel portion 4 and the toe portion 8 . After making the seamless woven part 2, the elastic strip 14 is attached along the four sides 9 to 12 with an adhesive, the first end 15 extending fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com