A woven mesh cylinder sieve

A technology of woven mesh and cylindrical screen, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of long manufacturing cycle and high manufacturing cost of cleaning machine screen cylinder, achieve low cost, prevent wire breakage, and reduce damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

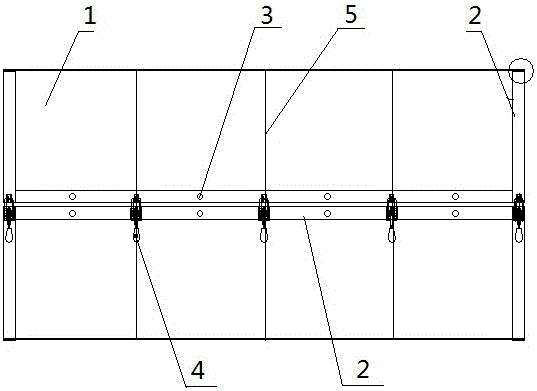

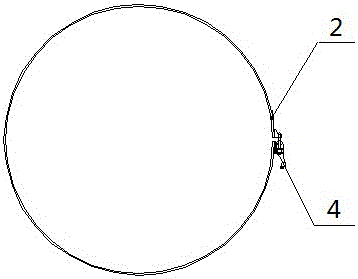

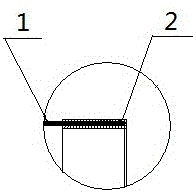

[0016] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] like Figure 1 to Figure 3 A woven mesh cylinder sieve is shown, the woven mesh screen body 1 is formed by curling a metal woven mesh into a cylindrical shape, the two ends of the woven mesh sieve body 1 are provided with edge strips 2, and the two ends of the woven mesh sieve body 1 Edge wrapping strips 2 are respectively provided on the butt joint sides, and positioning and fixing holes 3 are arranged on opposite sides of the two butt-joining edge wrapping strips 2 , and tensioning handles 4 are arranged on the positioning and fixing holes 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com