A kind of weaving method of silk mask cloth

A technology of silk mask, white factory silk, applied in the direction of textiles and papermaking, textiles, fabrics, etc., can solve skin irritation and other problems, and achieve the effect of reducing harm, reducing pollution, and good gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

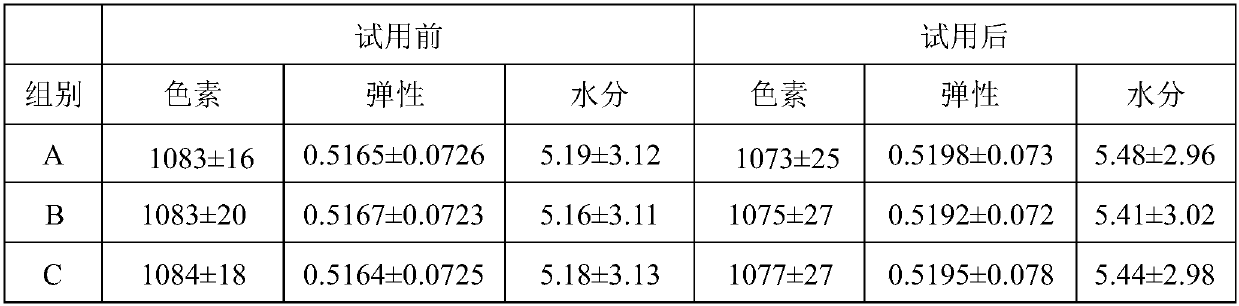

Examples

Embodiment 1

[0045] The present invention provides a kind of real silk face mask, is made by following steps:

[0046] 1. Weaving of silk mask cloth:

[0047] The silk mask cloth is woven from natural silk, which includes the following process steps in sequence: white factory silk inspection → soaking → drying → winding → paralleling → shaping → weft winding → warping → knotting → weaving → degumming .

[0048] (1) Raw material inspection: It is to check whether the raw materials of white factory silk meet the quality requirements such as fineness, strength, elongation, cohesion, moisture regain, cleanliness, and cleanliness. Pick out defects such as roughness and hard horniness to meet the requirements of subsequent weaving processes. The raw material can be 20 / 22DF1*2 factory silk;

[0049] (2) Foaming: Soak the white factory silk that meets the requirements in the foaming tank according to certain process conditions according to the requirements of the next process, such as: time, te...

Embodiment 2

[0083] The silk mask cloth is woven from natural silk, which includes the following process steps in sequence: white factory silk inspection → soaking → drying → winding → paralleling → shaping → weft winding → warping → knotting → weaving → degumming . Specifically:

[0084] (1) Raw material inspection: It is to check whether the raw materials of white factory silk meet the quality requirements such as fineness, strength, elongation, cohesion, moisture regain, cleanliness, and cleanliness. Pick out defects such as roughness and hard horniness to meet the requirements of subsequent weaving processes. The raw material can be 20 / 22DF1*2 factory silk;

[0085] (2) Foaming: Soak the white factory silk that meets the requirements in the foaming tank according to certain process conditions according to the requirements of the next process, such as: time, temperature, auxiliary agent and real silk foaming agent. , the soaking temperature is 60°C, the weft thread needs to be soaked...

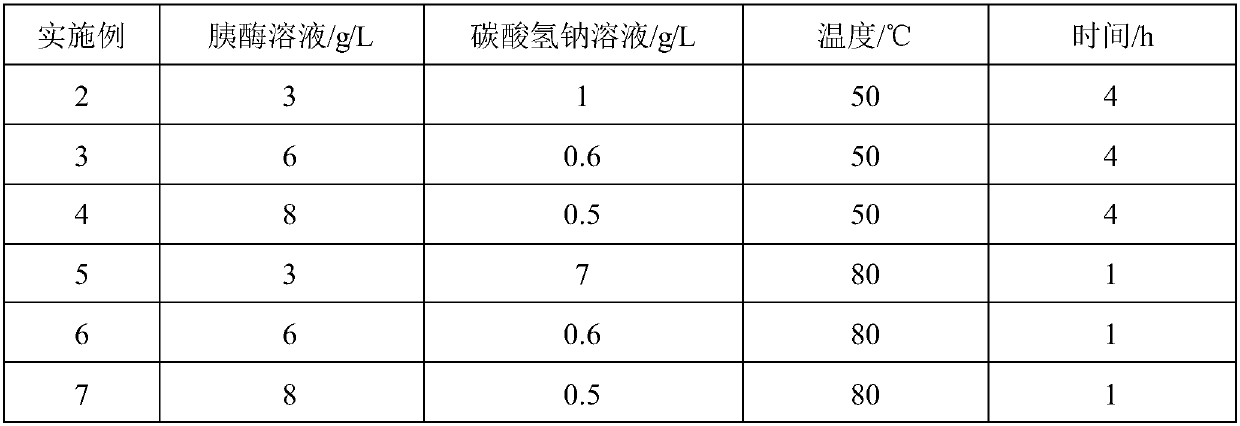

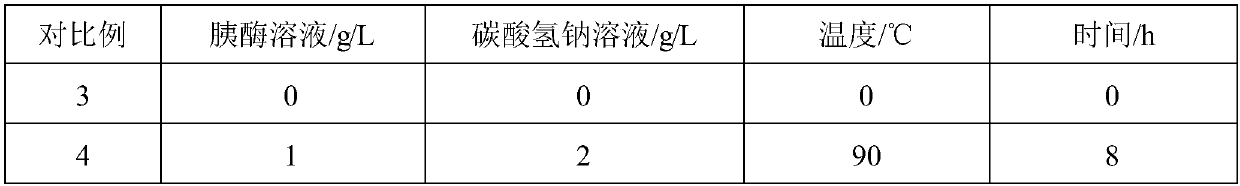

Embodiment 3

[0096] A method for weaving a silk mask cloth, the specific weaving process is the same as in Example 2, and the operating parameters of the degumming step are as shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com