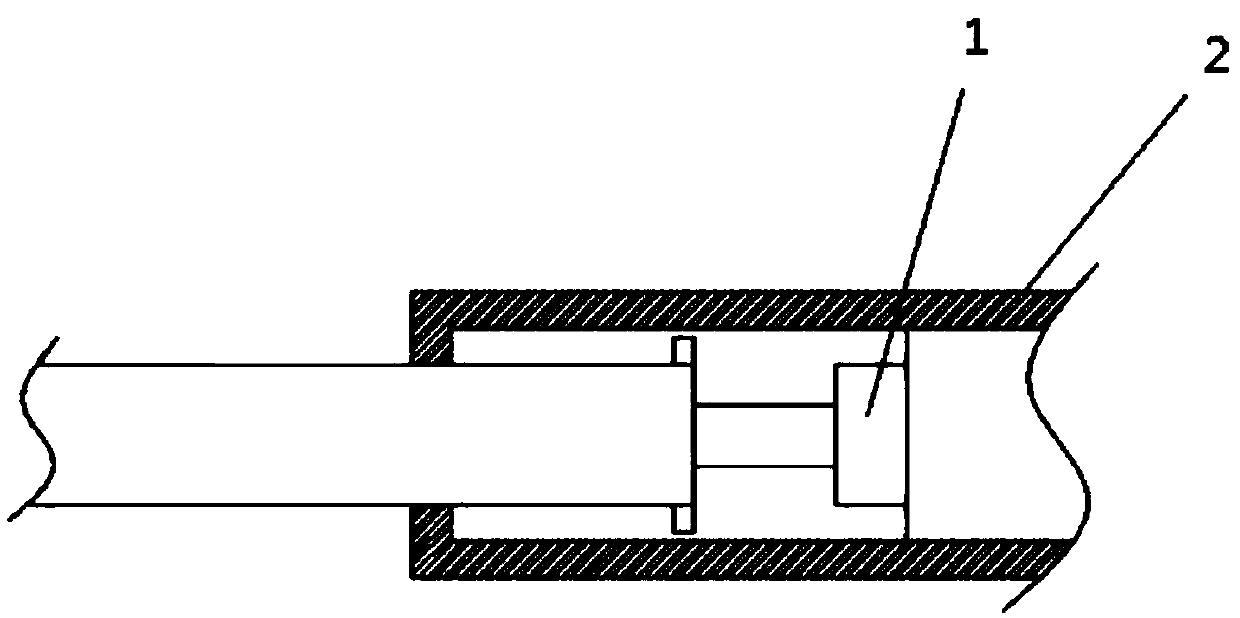

Pipe body shake removing mechanism for suction hose

A hose and tube body technology is applied in the field of suction hose tube body de-shake mechanism, which can solve the problems of low intelligence level of suction hose de-shake mode and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiment of the suction hose tube body deshaking mechanism of the present invention will be described in detail below with reference to the accompanying drawings.

[0021] According to the principle of function, the dust collector can be divided into the following five types:

[0022] 1. Dry mechanical dust collector mainly refers to the dust removal equipment designed by applying the action of dust inertia and gravity, such as high-concentration dust collectors such as settling chambers, inert dust collectors, and cyclone dust collectors, etc., mainly for high-concentration coarse particle dust. used for separation or concentration.

[0023] 2. Wet dust collectors rely on hydraulic affinity to separate and capture dust particles, such as spray towers, scrubbers, impact dust collectors, venturi tubes, etc., to deal with high concentrations and large air volumes that occur during the production process It is widely used in dusty gas occasions. For coarser, hydrop...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap