Automatic feeding and discharging production line for square steel

An automatic loading and unloading, production line technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of square steel edge damage, unable to meet the various needs of customers, unable to adapt to square steel of different diameters, etc. The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

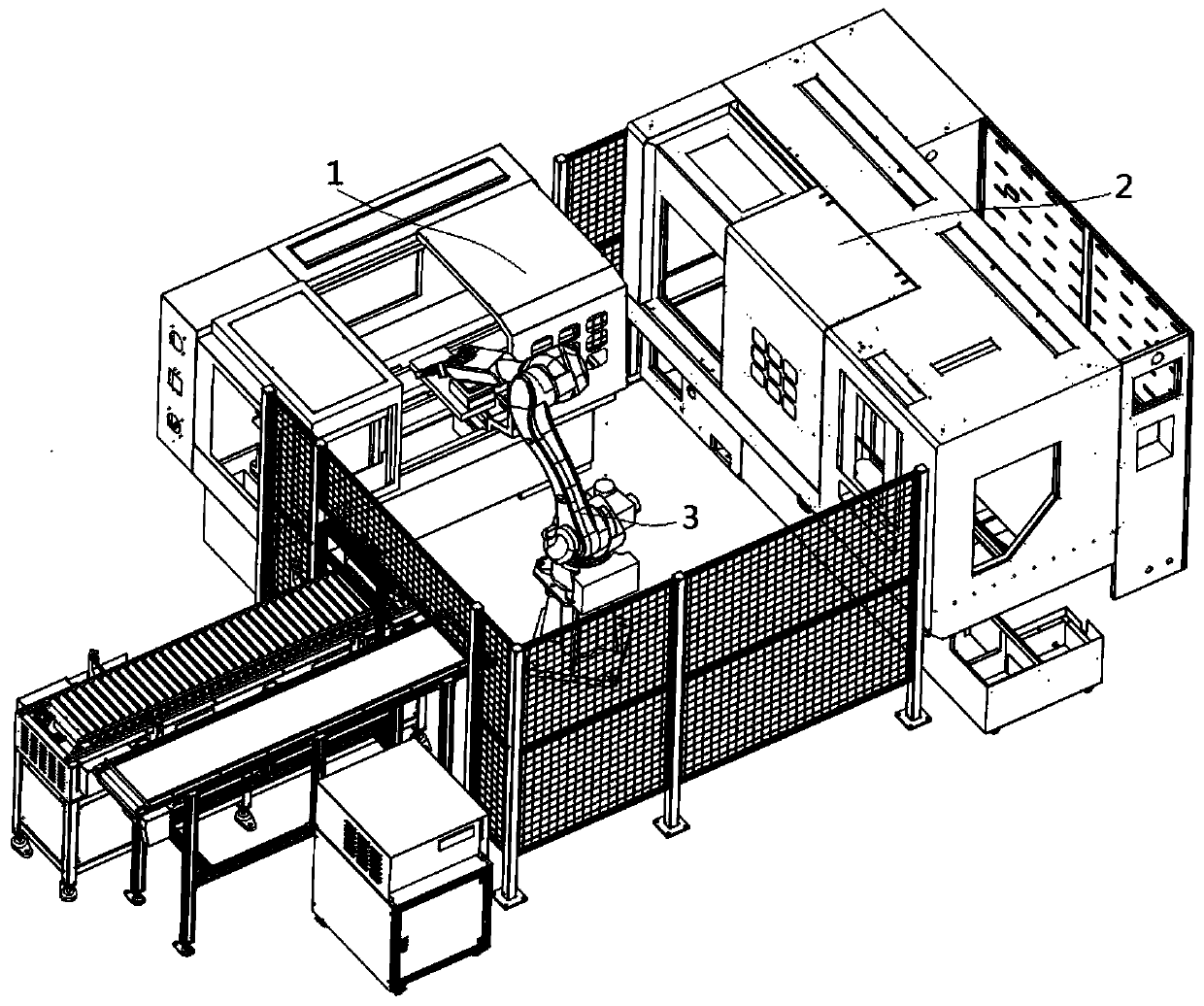

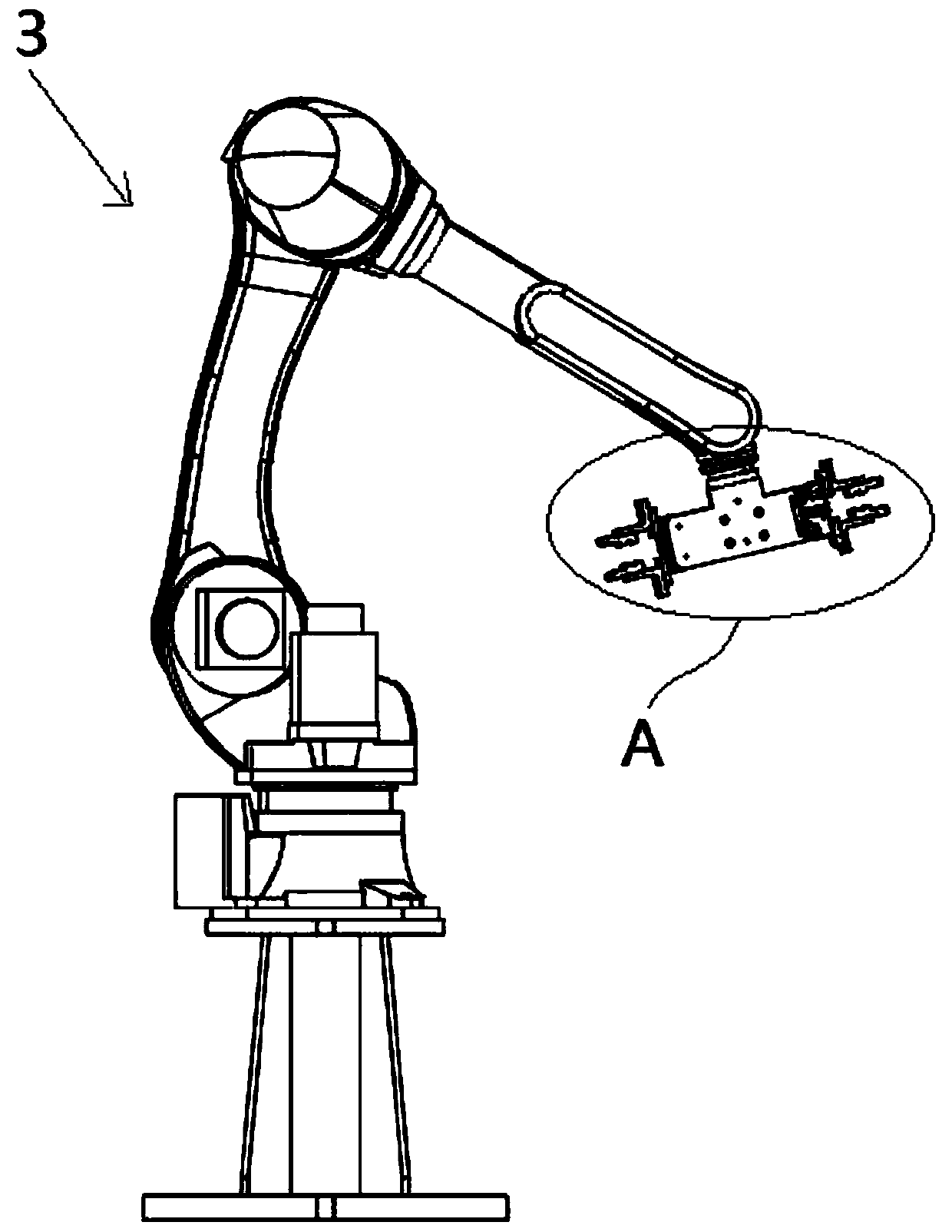

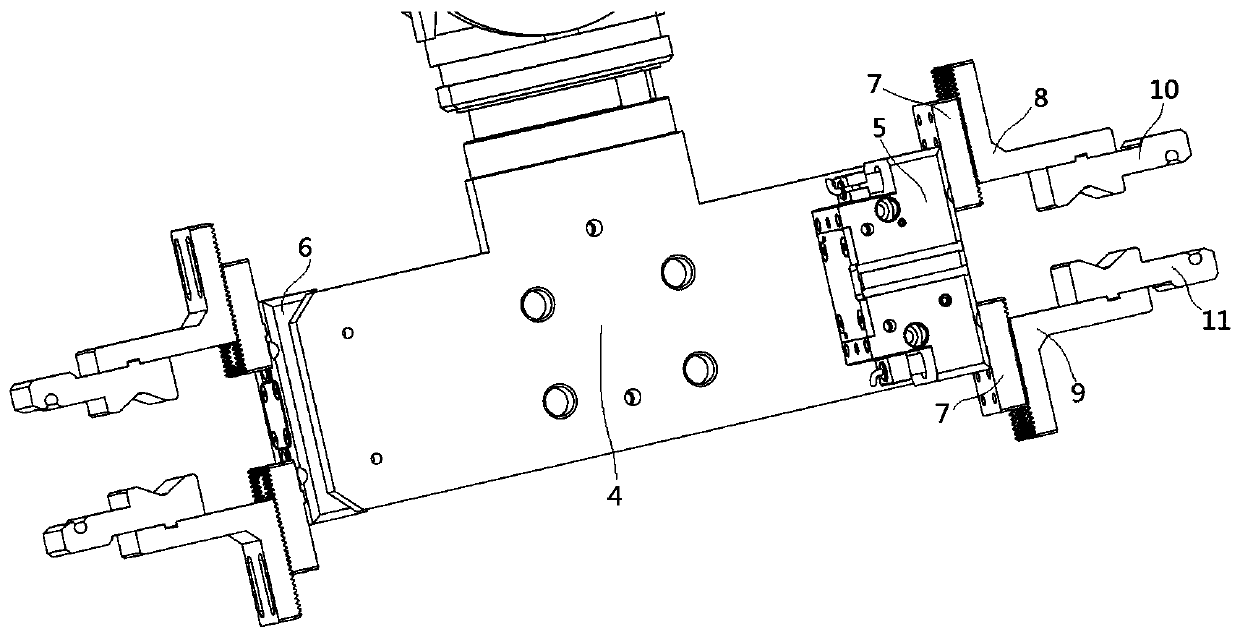

[0029] Such as Figure 1 to Figure 10 As shown, a square steel automatic loading and unloading production line proposed by the present invention includes a first processing unit 1 and a second processing unit 2 for processing the outer surface of the square steel. A robot 3 for carrying square steel is also arranged between the first processing unit 1 and the second processing unit 2; a rotating plate 4 is fixed on the moving end of the robot 3, and a first clip is fixed on the rotating plate 4 Holding the electric cylinder 5 and the second clamping electric cylinder 6, the output shafts of the first clamping electric cylinder 5 and the second clamping electric cylinder 6 are all to the outside of the rotating plate 4; the first...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap