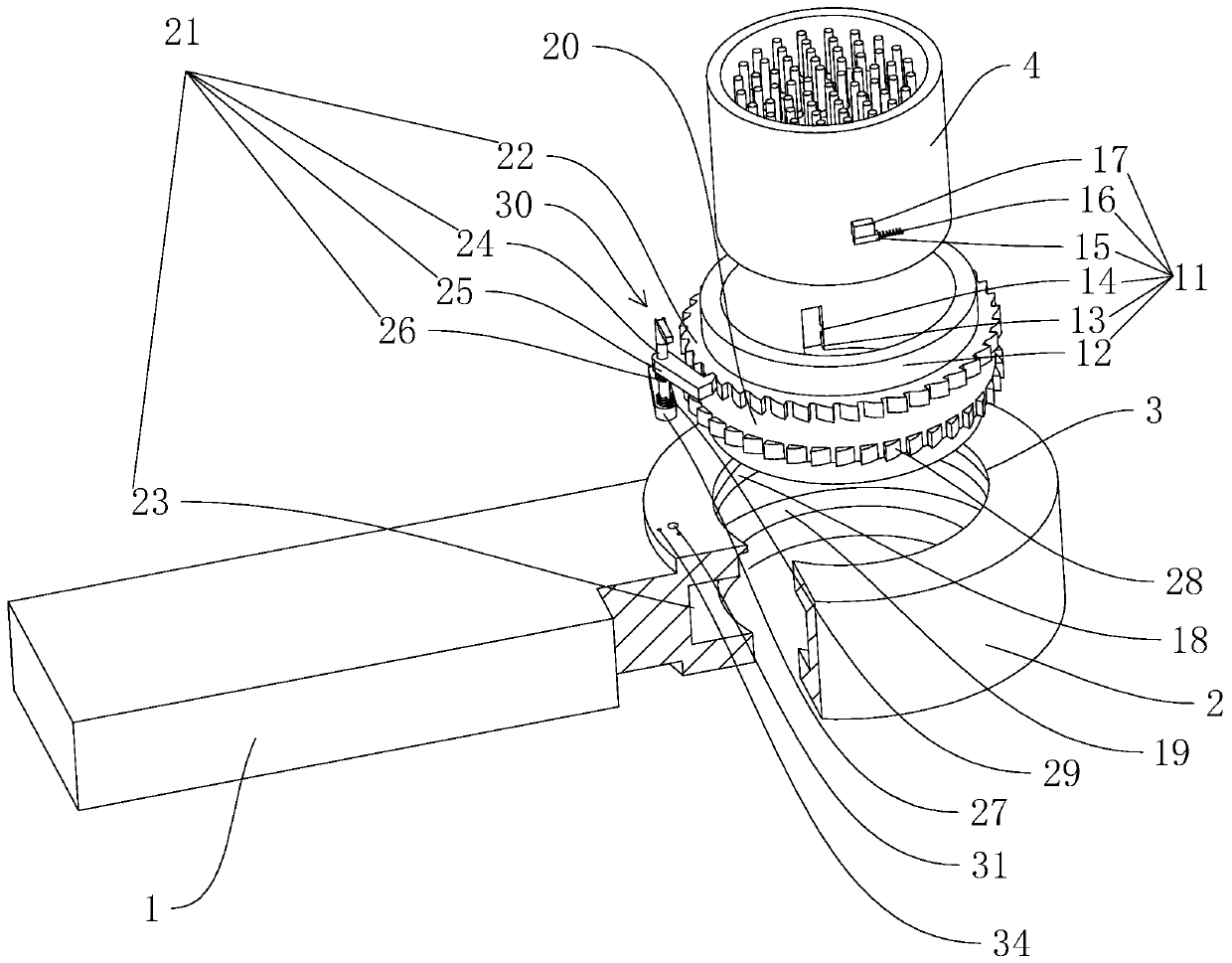

Torque wrench and steel box beam high-strength bolt tightening applying technology using same

A torque wrench and handle technology, applied to wrenches, screwdrivers, manufacturing tools, etc., can solve the problem of increasing the operator's carrying capacity, achieve the effect of reducing the number of wrenches and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

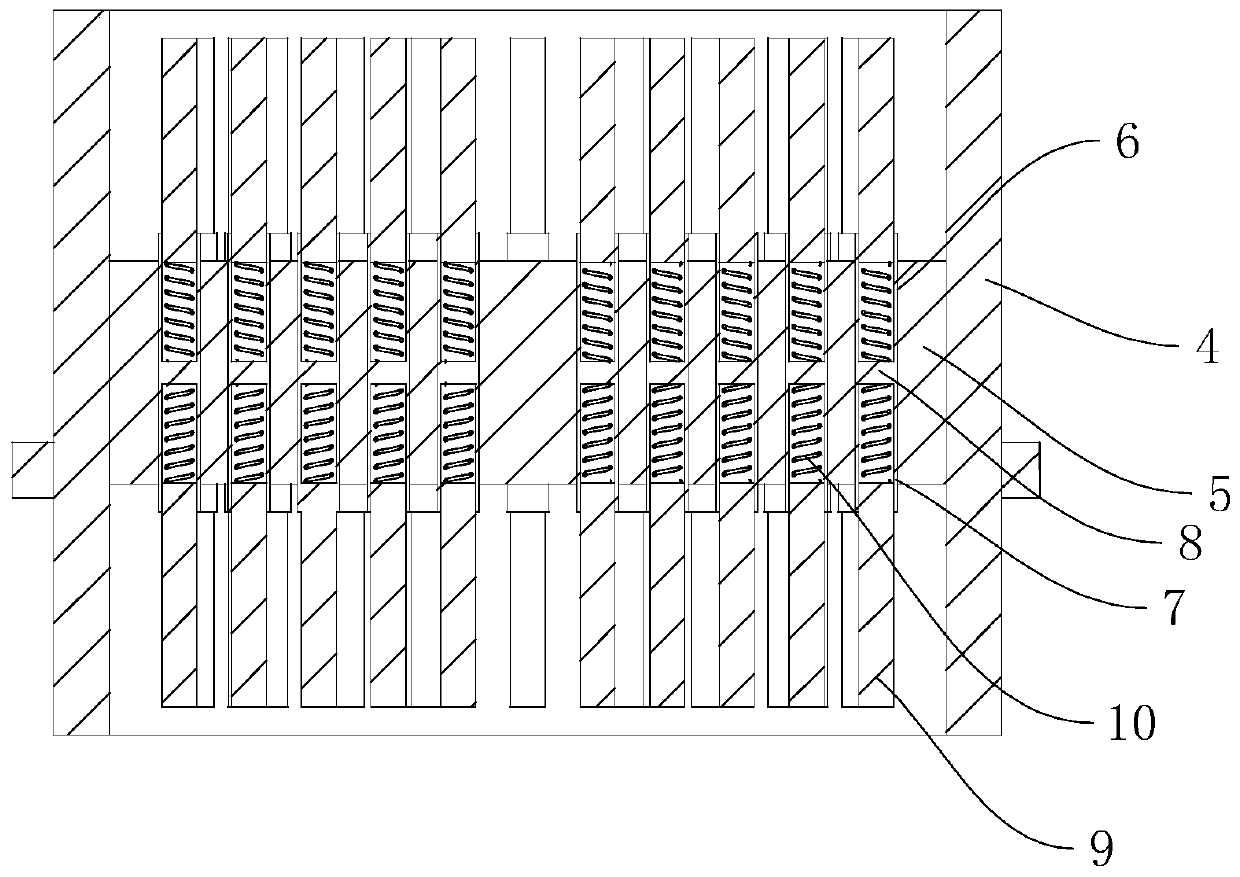

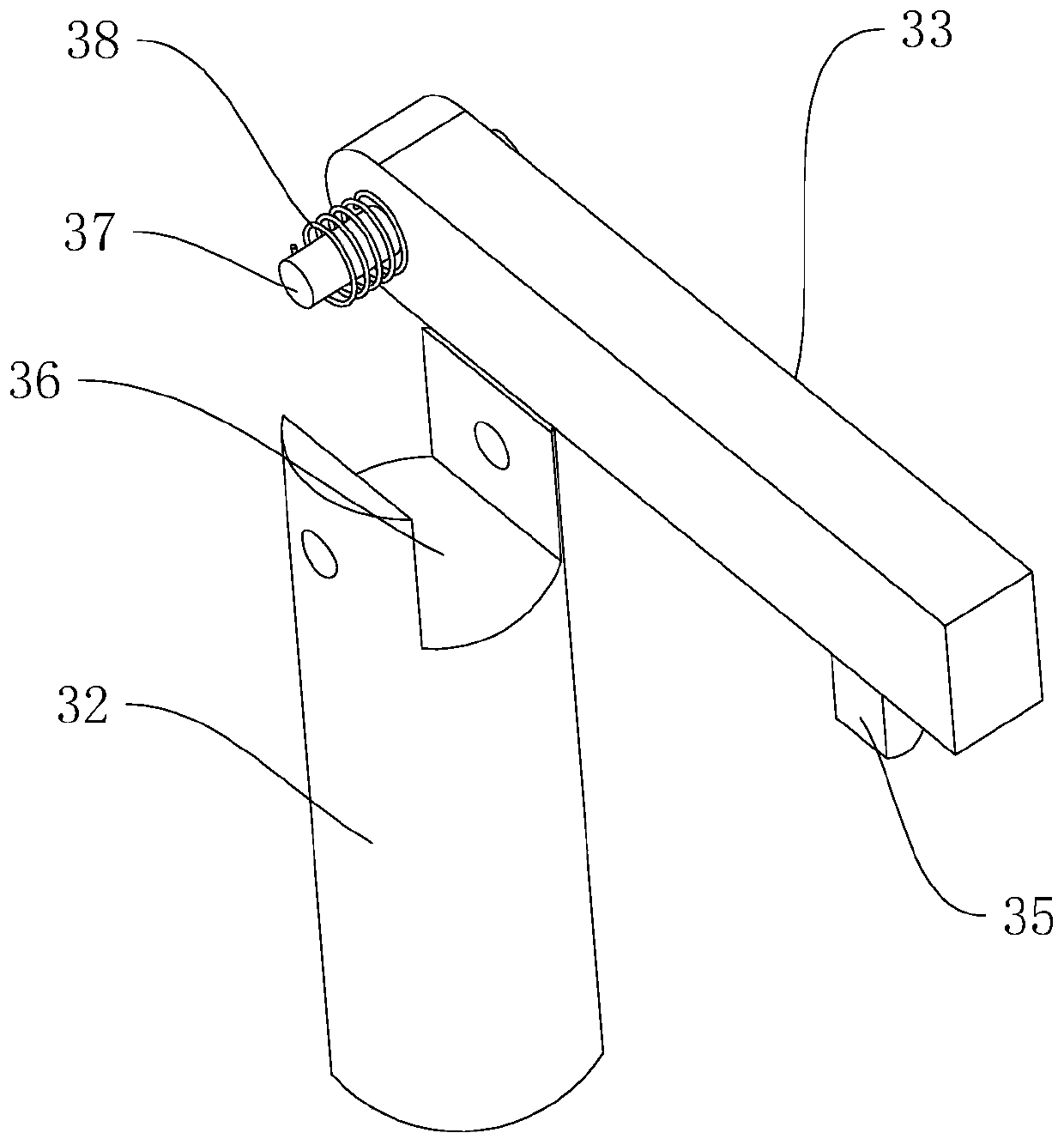

Method used

Image

Examples

Embodiment 2

[0041] Embodiment 2, the high-strength bolt screwing process of steel box girder, is characterized in that: comprising the following steps,

[0042] Step 1: Clean up the places where the steel box girder components need to be bolted;

[0043] Step 2, process the friction coefficient of the steel box girder members to be bolted to ensure that the friction coefficient is not less than 0.4;

[0044] Step 3, adjust the position of the steel box girder on the bridge, and adjust the position of the steel box girder components;

[0045] Step 4: Dry the bolt joints of the steel box girder components, and tighten the bolts with a torque wrench after the bolts are threaded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com