Wood-plastic window frame section bar forming mould

A technology for forming molds and window frames, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of not saving materials, unreasonable design of window frame forming molds, unsightly profiles, etc., and achieves good use effects. Practical use and promotion value, simple and practical effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

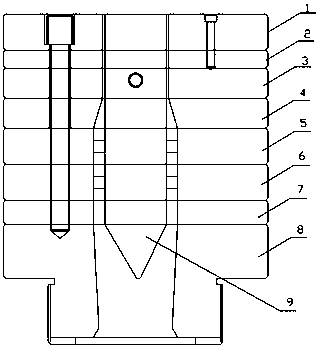

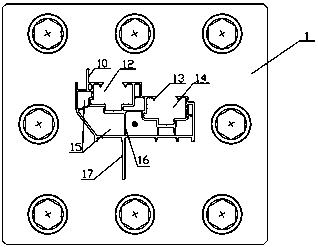

[0011] see Figure 1-2 , the present invention is a wood-plastic window frame profile forming mold, which is connected with a die a1, a die b2, a die c3, a manifold 4, a support plate a5, a support plate b6, and a transition plate 7 sequentially connected from top to bottom by screws , die body 8 and mandrel 9, the mold cavity formed by die a, die b, and die c includes a rectangular window frame opening A11 and a window frame opening B13 arranged from left to right, and the window frame opening The position of the mouth A is higher than that of the window frame opening B, the openings of the window frame opening A and the window frame opening B are arranged upwards, and the openings of the window frame opening A and the window frame opening B are facing Short ribs 12 are provided inside, and long ribs 10 are also provided outside the window frame opening A; several soundproof cavities 14 are arranged under the window frame opening A and window frame opening B, and all soundpro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com