Composite hydrophobic and waterproof coiled material

A waterproof membrane and waterproof board technology, which is applied in drainage, synthetic resin layered products, shaft lining, etc., can solve problems such as unsatisfactory waterproof and drainage effects, poor compressive performance, etc., to avoid water seepage and sedimentation, and improve use The effect of life and improvement of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Composite hydrophobic and waterproof membrane:

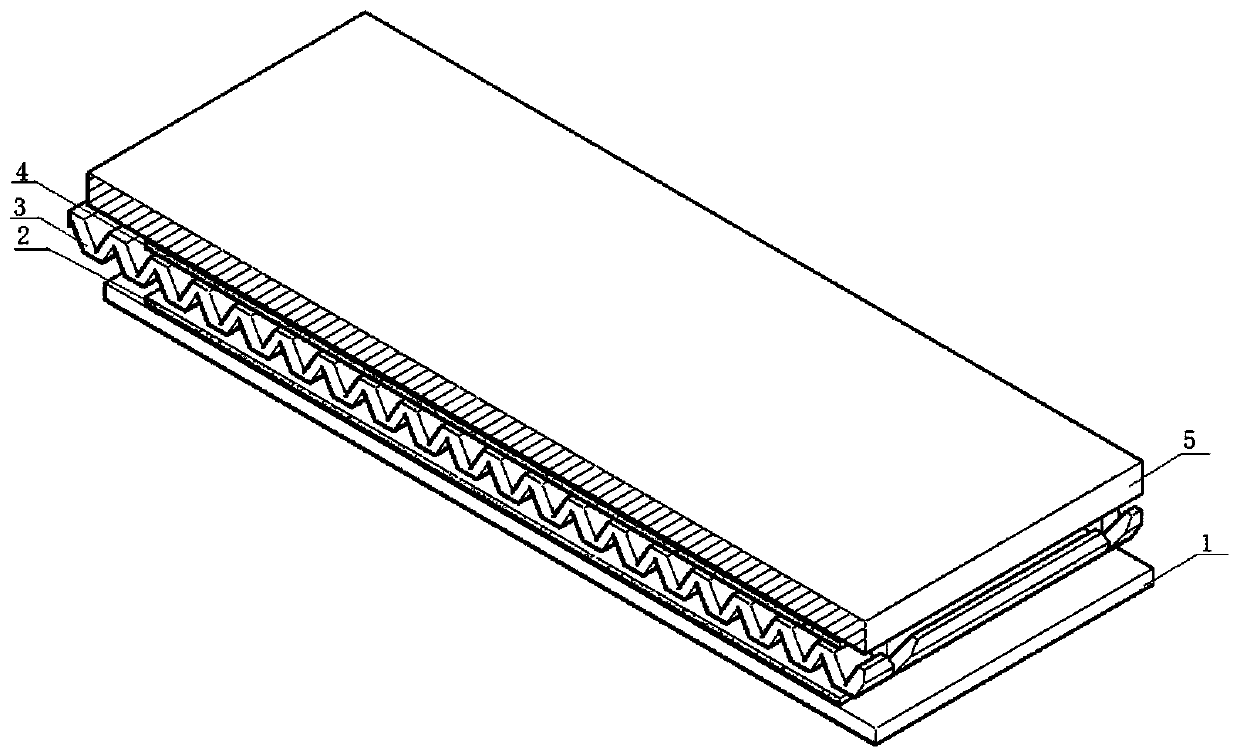

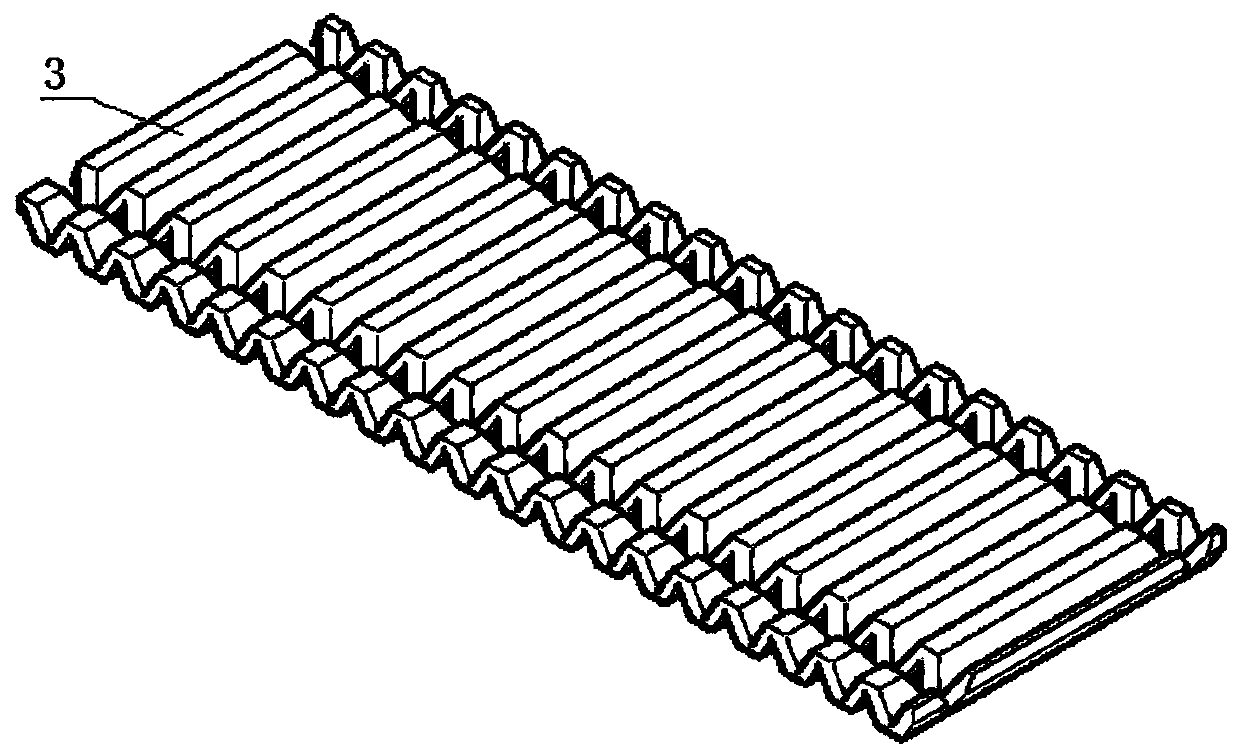

[0036] Such as figure 1 with figure 2 As shown, it includes a waterproof board layer 1, and a second non-woven fabric layer 2, a drainage layer 3 and a first non-woven fabric layer 4 arranged in sequence on the waterproof board layer, wherein the adjacent two layers are passed through thermal fusion or It is connected by glue, and at least one side of the drainage layer contains a concave well-shaped drainage groove, and the well-shaped drainage groove faces the tunnel primary lining. When both sides of the drainage layer contain well-shaped drainage grooves, they face the direction of the tunnel lining and the waterproof slab layer respectively. The first non-woven layer is in contact with the concrete surface 5 of the tunnel.

[0037] The drainage layer is made of nylon, which has superior aging resistance and compressive strength compared with the polypropylene material of conventional drainage boards...

Embodiment 2

[0044] Embodiment 2: Composite hydrophobic and waterproof membrane:

[0045] It includes a waterproof board layer, and a second non-woven fabric layer, a drainage layer and a first non-woven fabric layer arranged sequentially on the waterproof board layer, wherein the adjacent two layers are connected by hot-melt or adhesive, and the The drainage layer includes sunken well-shaped drainage grooves, and the first non-woven fabric layer is in contact with the concrete surface of the tunnel.

[0046] The drainage layer is made of nylon, which has superior aging resistance and compressive strength compared with the polypropylene material of conventional drainage boards.

[0047] The material of the waterproof board layer is polyester;

[0048] The mass per unit area of the first non-woven fabric layer is 200g / m 2 ;

[0049] The thickness of the drainage layer is 20mm.

[0050] The drainage layer is horizontally arranged with nylon filaments staggered to form a W-shaped path, ...

Embodiment 3

[0053] Embodiment 3: Composite hydrophobic and waterproof membrane:

[0054] It includes a waterproof board layer, and a drainage layer and a first non-woven fabric layer arranged sequentially on the waterproof board layer, wherein the adjacent two layers are connected by hot-melt or adhesive, and the drainage layer contains a concave well-shaped The drainage channel, the first non-woven fabric layer is in contact with the concrete surface of the tunnel.

[0055] The drainage layer is made of nylon, which has superior aging resistance and compressive strength compared with the polypropylene material of conventional drainage boards.

[0056] The material of the waterproof board layer is polyester;

[0057] The mass per unit area of the first non-woven fabric layer is 100g / m 2 ;

[0058] The thickness of the drainage layer is 10mm.

[0059] The drainage layer is horizontally arranged with nylon filaments staggered to form a W-shaped path, forming a longitudinal drainage gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com