A method for preparing cerium phosphate by utilizing waste liquid containing tetravalent cerium

A cerium phosphate and waste liquid technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of low cerium recovery efficiency and low cerium recovery yield, and achieve improved reduction efficiency and obvious environmental friendliness. , the effect of increasing the probability of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

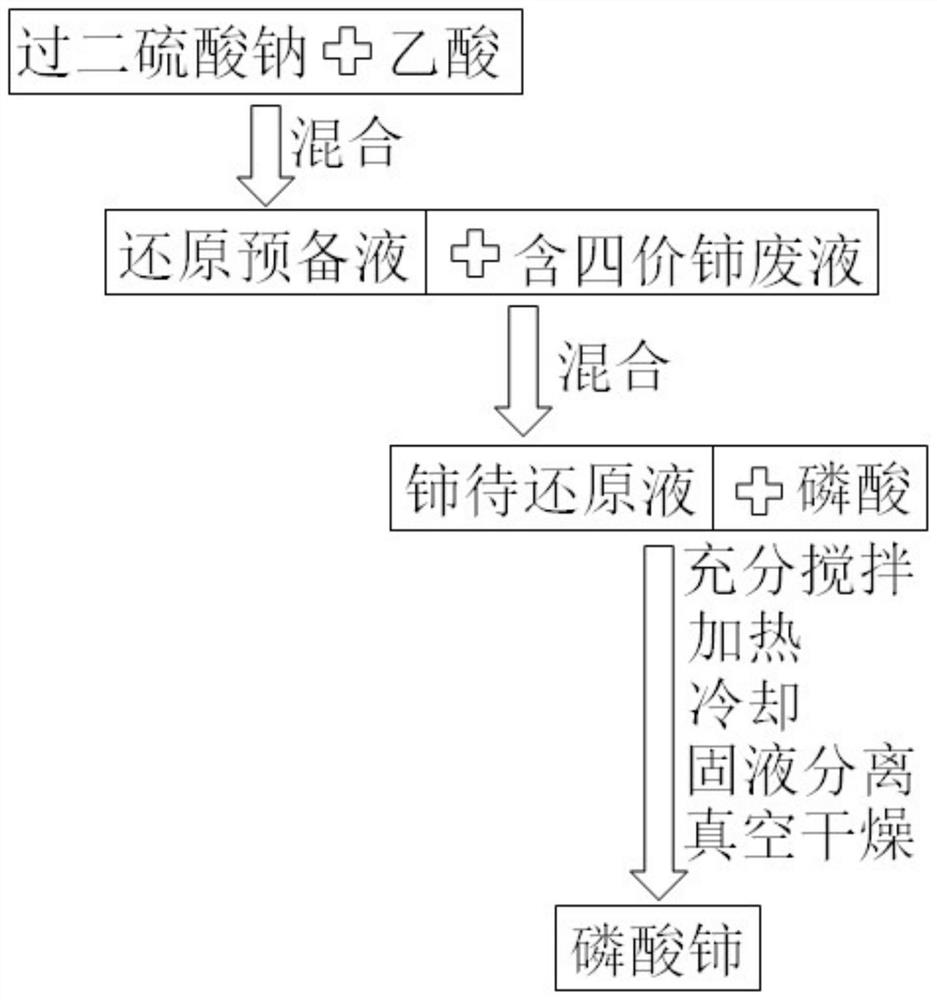

Method used

Image

Examples

Embodiment 1

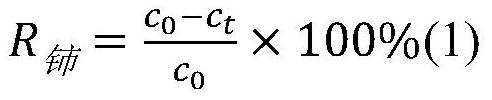

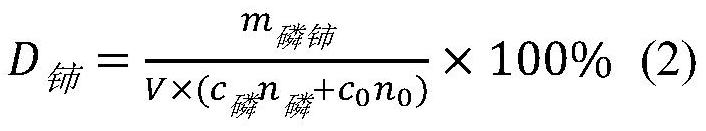

[0019] Embodiment 1 persulfate radical and acetic acid molar ratio influence on cerium recovery rate and cerium phosphate yield rate

[0020] The method for preparing cerium phosphate by using tetravalent cerium-containing waste liquid: according to the molar ratio of persulfate and acetic acid 0.1:1, 0.15:1, 0.18:1, 0.2:1, 0.4:1, 0.6:1, 0.62:1, 0.65 :1, 0.7:1 Weigh sodium peroxodisulfate and acetic acid respectively, mix, stir until sodium peroxodisulfate is completely dissolved, and obtain nine groups of reduction preparation solutions. Mix the tetravalent cerium-containing waste liquid with the nine groups of reduction preparation solutions at a volume ratio of 1:2 to obtain nine groups of cerium-to-be-reduced solutions, wherein the concentration of tetravalent cerium in the tetravalent cerium-containing waste liquid is 0.05M. Add 0.1M phosphoric acid to the nine groups of cerium phosphates to be reduced respectively, stir thoroughly, heat at 70°C for 5 minutes, cool, separ...

Embodiment 2

[0027] The influence of concentration of tetravalent cerium on cerium recovery rate and cerium phosphate yield in embodiment 2 waste liquid

[0028] The method for preparing cerium phosphate by using tetravalent cerium-containing waste liquid: Weigh sodium peroxodisulfate and acetic acid according to the molar ratio of persulfate to acetic acid 0.6:1, mix and stir until sodium peroxodisulfate is completely dissolved to obtain a reduction preparation solution. Mix nine groups of tetravalent cerium-containing waste liquids with nine groups of reduction preparation solutions at a volume ratio of 1:2.5 to obtain nine groups of cerium-containing waste liquids to be reduced, and the concentrations of tetravalent cerium in the nine groups of tetravalent cerium-containing waste liquids are respectively 0.025M , 0.035M, 0.045M, 0.05M, 0.1M, 0.15M, 0.155M, 0.165M, 0.175M. Add 0.2M phosphoric acid to the nine groups of cerium phosphates to be reduced respectively, stir well, heat at 85°C...

Embodiment 3

[0033] Embodiment 3 phosphoric acid concentration affects cerium recovery rate and cerium phosphate yield rate

[0034]The method for preparing cerium phosphate by using tetravalent cerium-containing waste liquid: Weigh sodium peroxodisulfate and acetic acid according to the molar ratio of persulfate to acetic acid 0.6:1, mix and stir until sodium peroxodisulfate is completely dissolved to obtain a reduction preparation solution. Mix the tetravalent cerium-containing waste liquid with the reduction preparation solution at a volume ratio of 1:3 to obtain the cerium-to-be-reduced liquid, wherein the tetravalent cerium concentration in the tetravalent cerium-containing waste liquid is 0.15M. Add 0.05M, 0.07M, 0.09M, 0.1M, 0.2M, 0.3M, 0.31M, 0.33M, 0.35M phosphoric acid into the nine groups of cerium to be reduced, stir well, heat at 100°C for 15 minutes, cool , solid-liquid separation, and vacuum drying to obtain nine groups of cerium phosphate.

[0035] The detection of cerium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com