Efficient nanometer vacuum evaporation source

A technology of vacuum evaporation and evaporation source, which is applied in the direction of vacuum evaporation plating, ion implantation plating, metal material coating process, etc., to achieve the effect of rotating and cleaning, reducing the scattering area, and ensuring the efficiency of evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

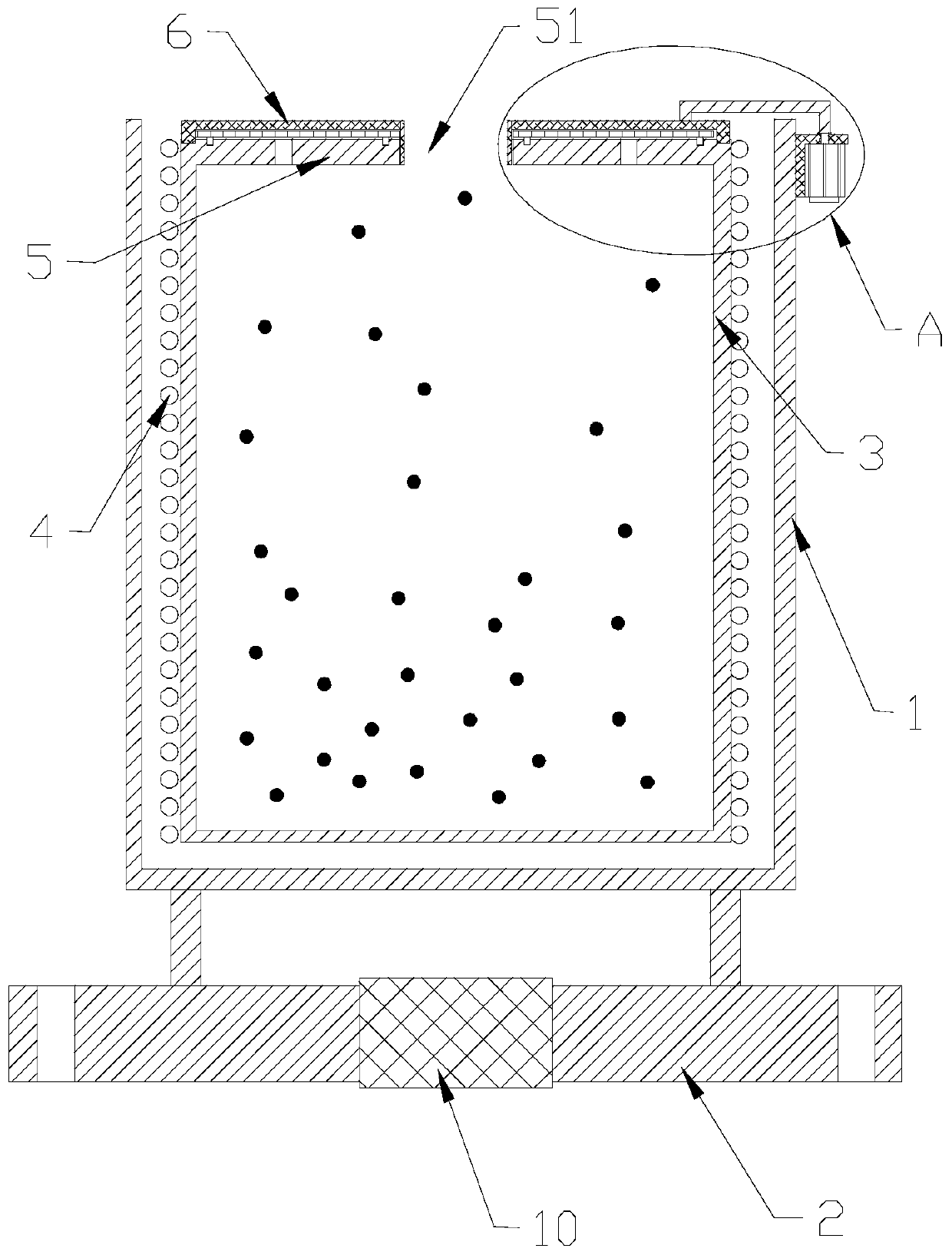

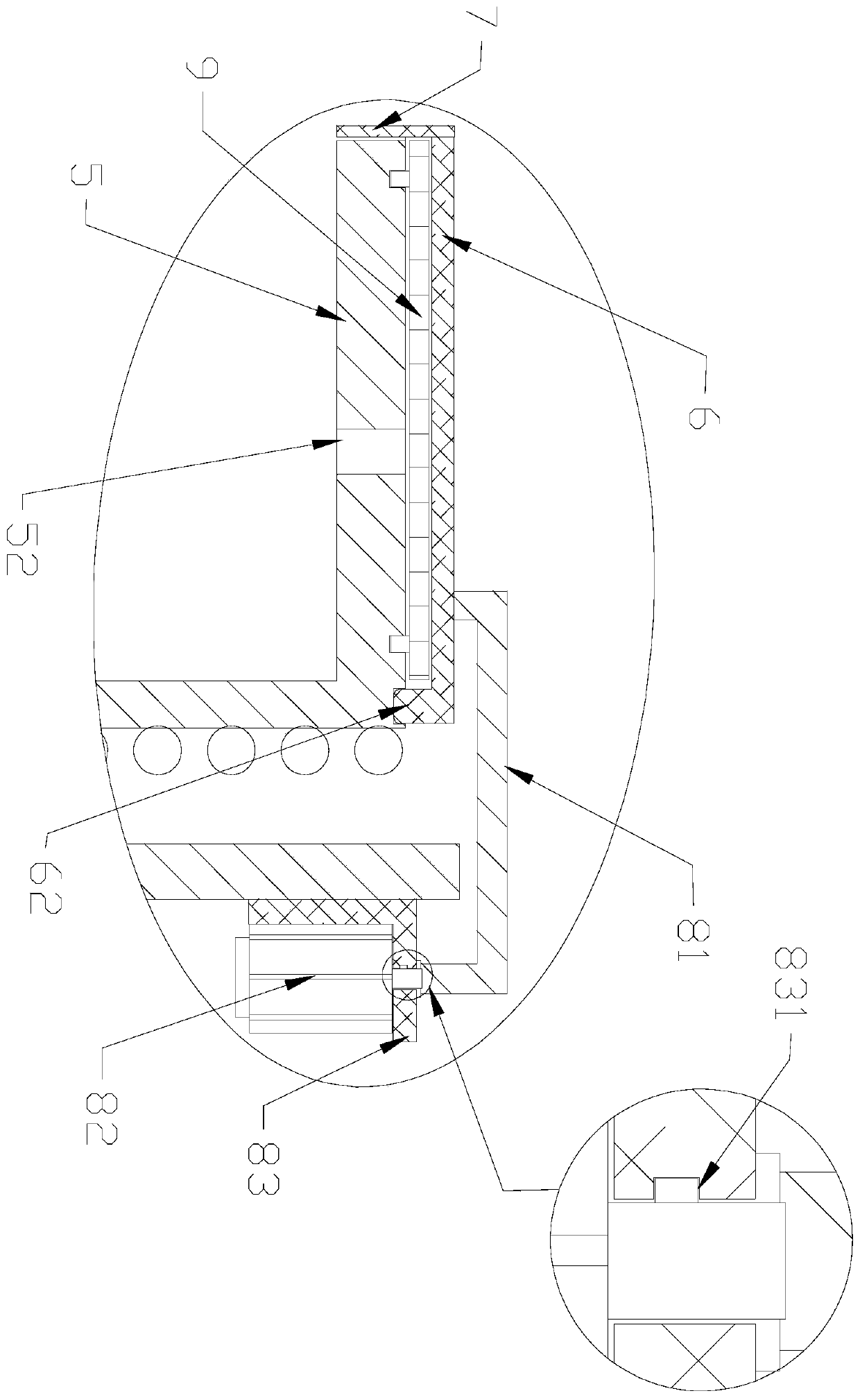

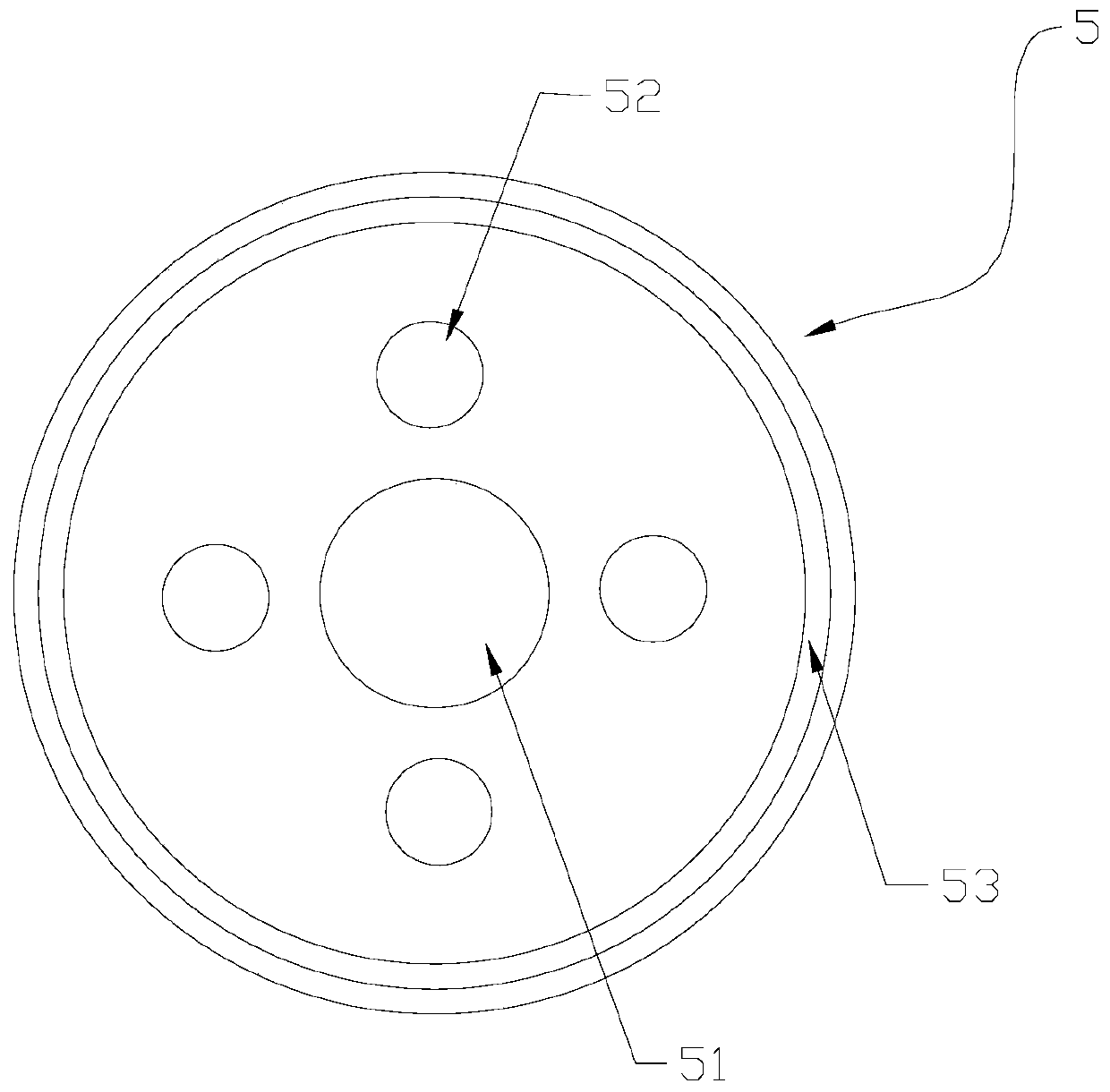

[0022] See attached Figure 1-5 As shown, a high-efficiency nano-vacuum evaporation source of the present invention includes a heat shield assembly 1 with an open top, the bottom of the heat shield assembly 1 is connected to a vacuum flange 2, and a crucible assembly for loading source materials is provided inside . The crucible assembly includes a U-shaped crucible 3, a No. 1 heating assembly 4 is wound around the outer wall of the U-shaped crucible 3, and a cover plate 5 integrally formed with it is provided on the top of the U-shaped crucible 3. The middle part of the cover plate 5 is provided with an evaporation opening 51 , and the top of the cover plate 5 is provided with a rotatable top cover 6 . The upper end of the top cover 6 is connected to the driving element fixedly connected to the heat shield assembly 1 , and a through hole matching the evaporation opening 51 is provided in the middle. A cleaning piece for cleaning the evaporation opening 51 is provided in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com