Road paver for road construction

A road construction and paver technology, applied in the direction of roads, roads, road repair, etc., can solve problems such as height difference, poor compression resistance of asphalt roads, and asphalt dilution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

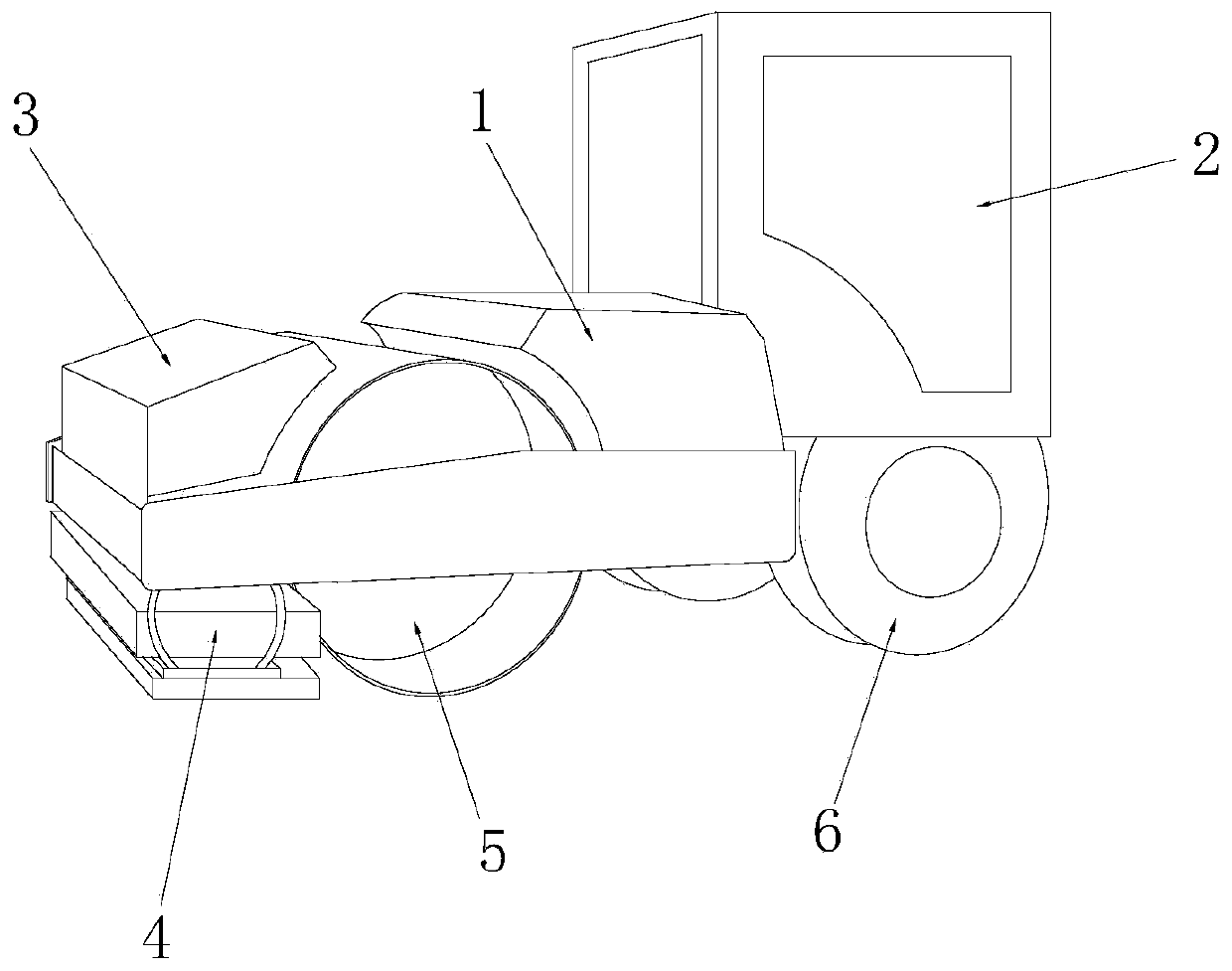

[0029] Such as Figure 1-Figure 4 Shown, the present invention provides a kind of technical scheme of road construction paver:

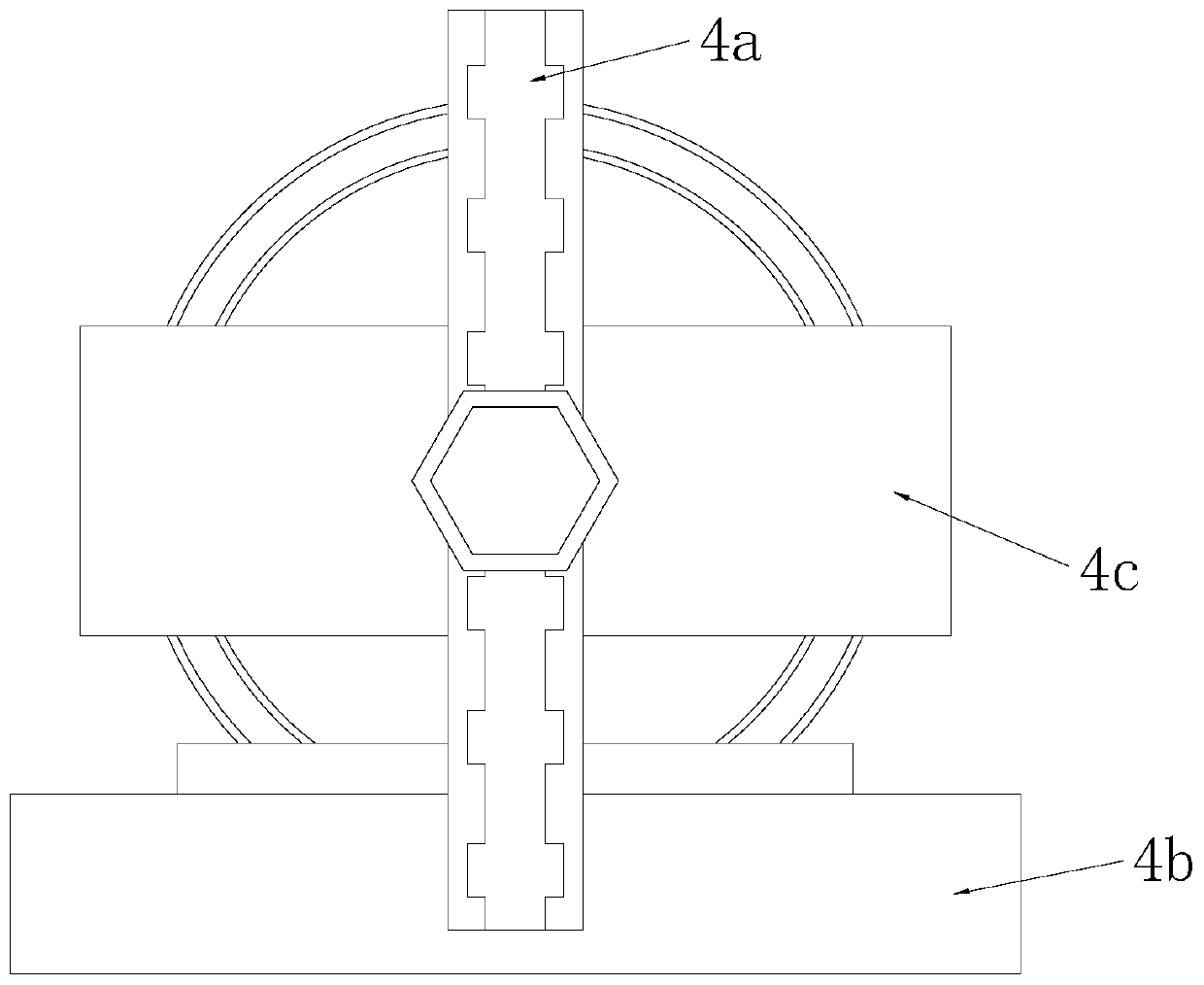

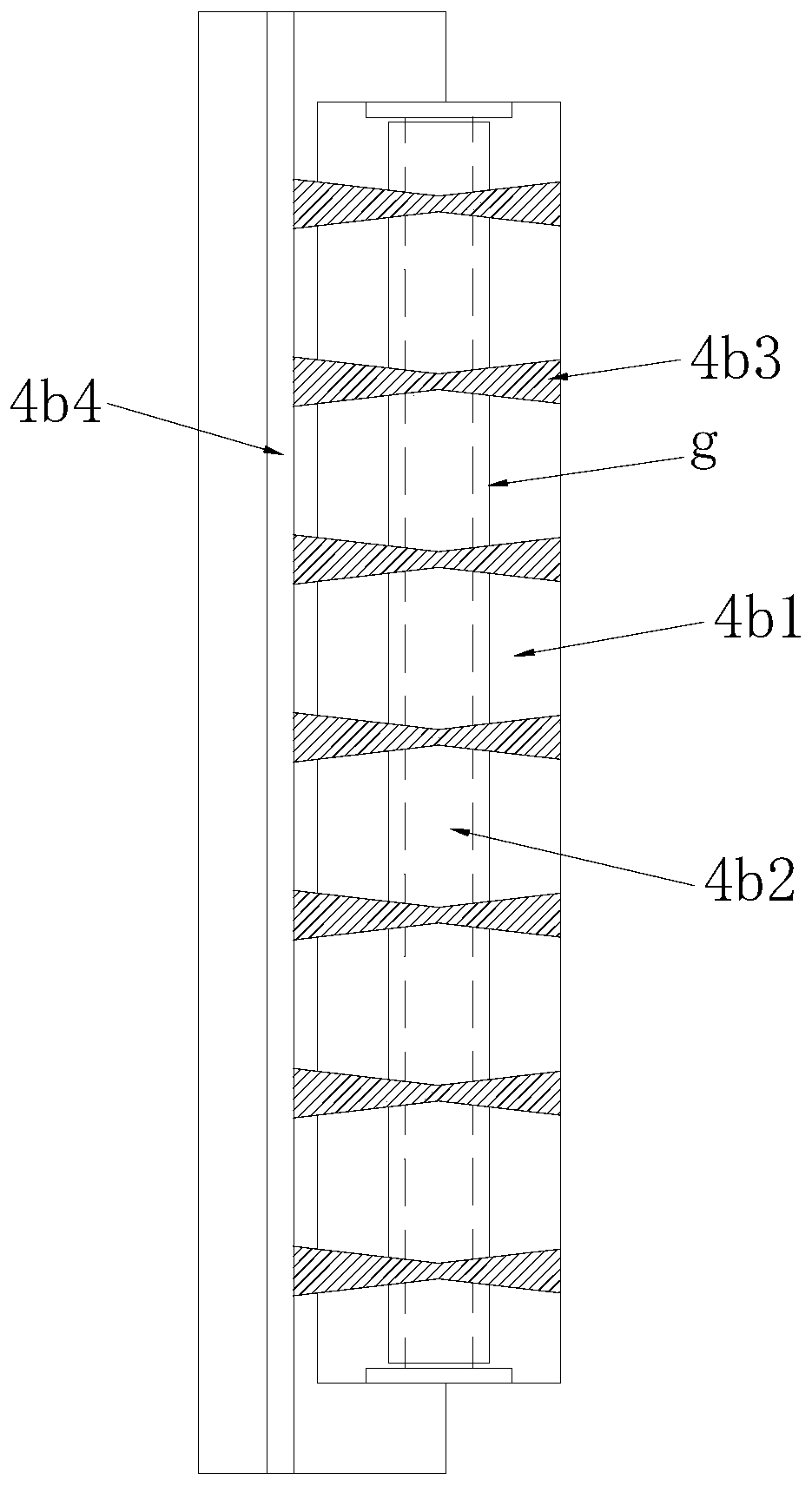

[0030] Such as Figure 1-Figure 2 As shown, a road construction paver has a structure including a car body 1, a control room 2, a driving box 3, a pressing device 4, a paving shaft 5, and a moving wheel 6. The control room 2 is installed on the upper surface of the car body 1. The rear side is connected by electric welding. The drive box 3 is installed on the front side of the upper surface of the car body 1 and connected by electric welding. The pressing device 4 is arranged on the front side of the lower surface of the car body 1 and is positioned in front of the paving shaft 5. The pressing device 4 is connected to the car body 1 by electric welding, and the moving wheels 6 are symmetrically installed on the rear side of the lower surface of the car body 1 and connected by buckling. The pressing device 4 includes an adjusting buckle plate 4a , s...

no. 2 example

[0040] Such as figure 1 , figure 2 , Figure 5 Shown, the present invention provides a kind of technical scheme of road construction paver:

[0041] Such as Figure 1-Figure 2 As shown, a road construction paver has a structure including a car body 1, a control room 2, a driving box 3, a pressing device 4, a paving shaft 5, and a moving wheel 6. The control room 2 is installed on the upper surface of the car body 1. The rear side is connected by electric welding. The drive box 3 is installed on the front side of the upper surface of the car body 1 and connected by electric welding. The pressing device 4 is arranged on the front side of the lower surface of the car body 1 and is positioned in front of the paving shaft 5. The pressing device 4 is connected to the car body 1 by electric welding, and the moving wheels 6 are symmetrically installed on the rear side of the lower surface of the car body 1 and connected by buckling. The pressing device 4 includes an adjusting buckl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com