A method and system for estimating the temperature of the rotor magnet of a permanent magnet synchronous motor

A permanent magnet synchronous motor and rotor technology, applied in the control system, control generator, vector control system, etc., can solve the problems of large rotor temperature error, difficult thermal management of motor rotor, magnetic steel demagnetization, etc., to improve torque output Accuracy, demagnetization prevention, and reliability improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

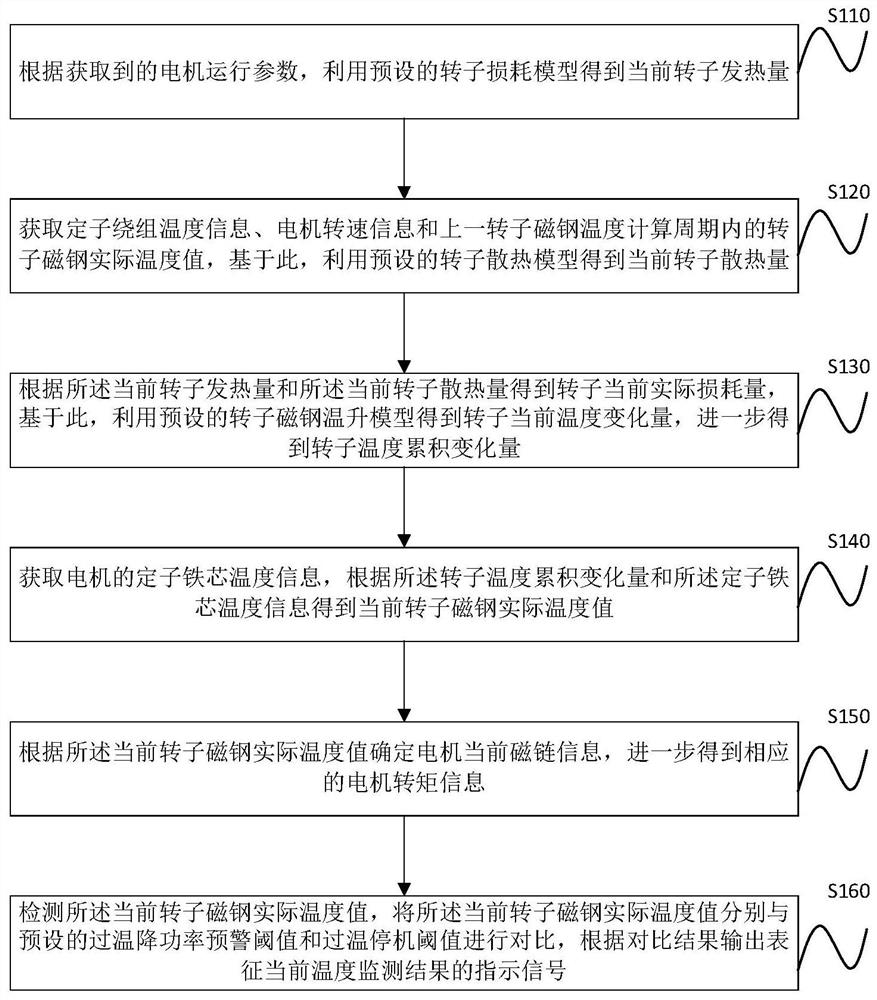

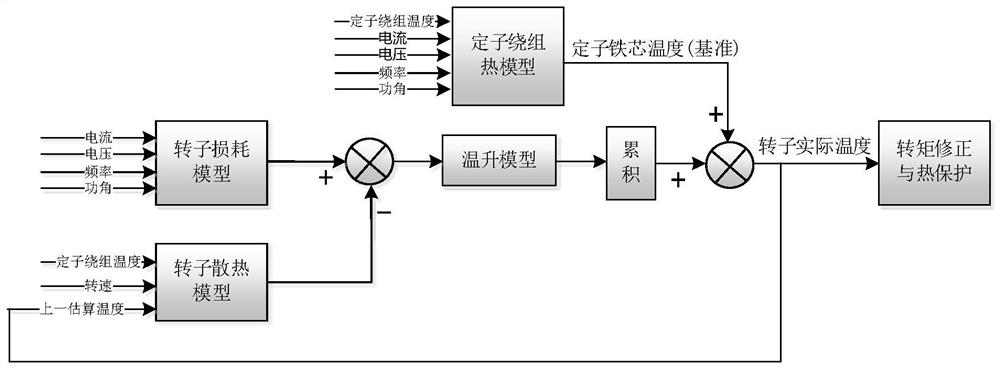

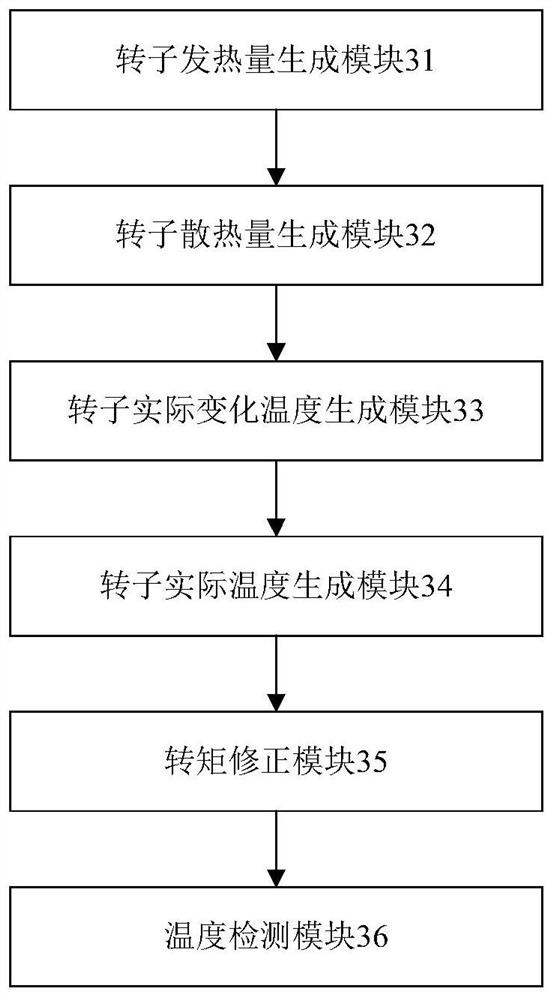

[0026] figure 1 It is a step chart of the method for online estimation of the temperature of the rotor magnetic steel of the permanent magnet synchronous motor according to the embodiment of the present application. figure 2 It is a schematic diagram of the principle of the method for online estimation of the temperature of the rotor magnetic steel of the permanent magnet synchronous motor according to the embodiment of the present application. Combine below figure 1 and figure 2 The online estimation method for the temperature of the rotor magnetic steel of the permanent magnet synchronous motor in the embodiment of the present invention will be described.

[0027] In step S110, the motor operating parameters are obtained, and the current calorific value of the rotor is obtained by using a preset rotor loss model according to the motor operating parameters obtained in real time. Wherein, the motor operating parameters at least include: current information, voltage inform...

Embodiment 2

[0049] refer again figure 1 and figure 2 , after obtaining the actual rotor magnet temperature value in the current rotor magnet temperature calculation period through the above steps S110 to S140, enter into step S150.

[0050] In step S150, the current flux linkage information of the motor is determined according to the actual rotor magnet temperature value in the current rotor magnet temperature calculation period, and the corresponding motor torque information is further obtained. Specifically, determine the corresponding magnetic energy product curve according to the material of the rotor magnet, and further determine the preset temperature flux linkage change relationship curve corresponding to the magnetic energy product curve; according to the actual temperature value of the rotor magnet steel, use the temperature flux linkage change relationship curve , get the current flux information of the motor, and further get the torque information of the motor.

[0051]Furth...

Embodiment 3

[0056] refer again figure 1 and figure 2 After obtaining the actual temperature value of the rotor magnet steel in the current calculation period of the rotor magnet steel temperature through the above steps S110 to S140, it further enters step S160. In step S160, the current actual temperature value of the rotor magnet is detected, and the current actual temperature value of the rotor magnet is compared with the preset over-temperature warning threshold, over-temperature drop power warning threshold and over-temperature shutdown threshold, respectively. According to the comparison results, An indication signal representing the current temperature monitoring result is output. Further, the corresponding indication signal is sent to the motor driving device in the motor controller, so as to control the motor driving device to operate in combination with the above indication signal. Furthermore, through devices such as relevant indicator lights or displays connected to the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com