A Torque Control Method of Bolt Wrench Based on Fuzzy PID

A torque control and fuzzy technology, which is applied to wrenches, screwdrivers, manufacturing tools, etc., can solve problems such as low control accuracy, potential safety hazards, and torque sensor display errors, so as to improve torque output accuracy, maintain stable performance, and strong anti-interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

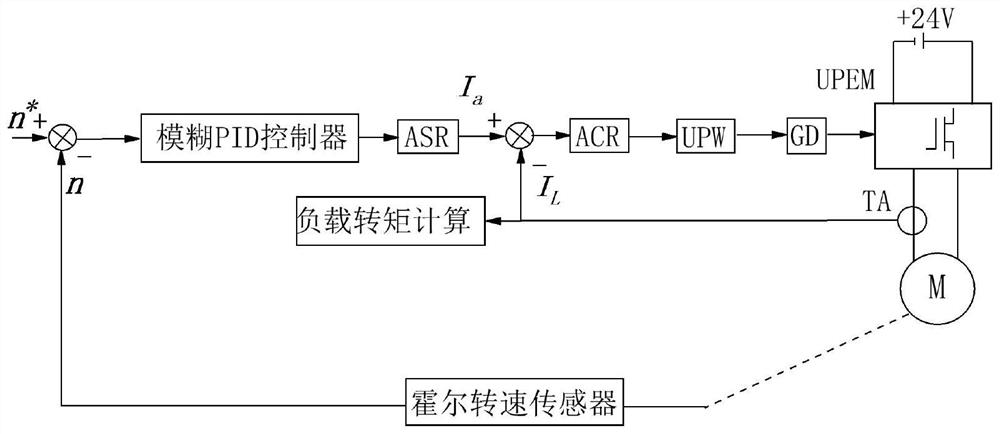

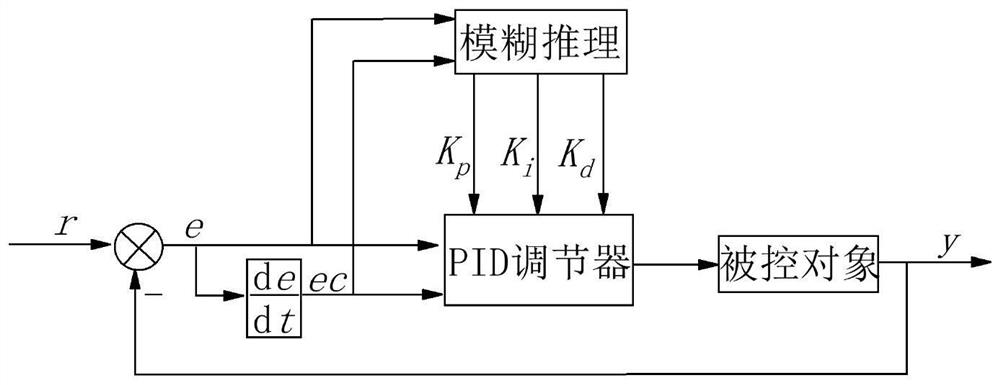

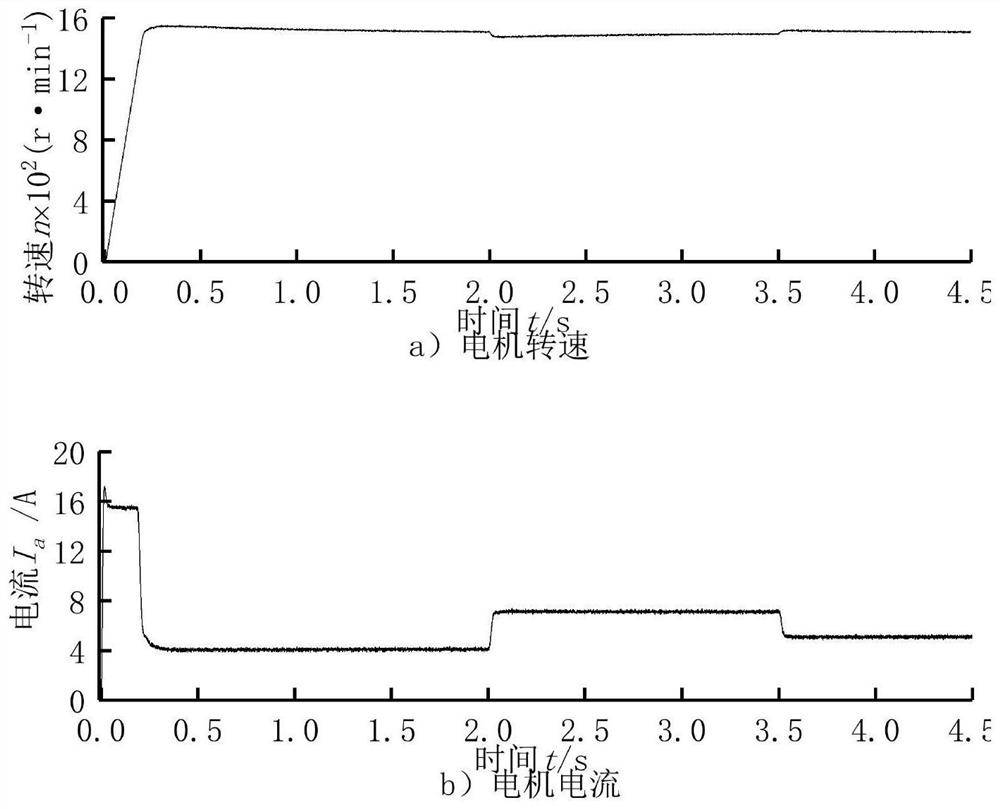

[0048] First construct the bolt wrench torque control frame diagram, through the analysis of DC brush motor torque output characteristics, combined with Newton's second law and motor torque balance equation to establish a mathematical model, then use the fuzzy PID controller as the speed outer loop regulator, and the inner loop uses PID The current control loop of the algorithm uses the current sensor and Hall speed sensor to collect the current and speed of the motor during rotation, and the mathematical model can accurately calculate the torque and control the output.

[0049] Control method of the present invention comprises the following steps:

[0050] Step A, by analyzing the torque output characteristics of the DC brushed motor, combining Newton's second law and the motor torque balance equation to establish a mathematical model, the rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com