Automatic furniture paint spray room

A furniture spraying and furniture technology, applied in spraying rooms, spraying devices, etc., can solve problems such as operator's health injury, operator inhalation of a large amount of powder paint mist, etc., and achieve the effect of improving painting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

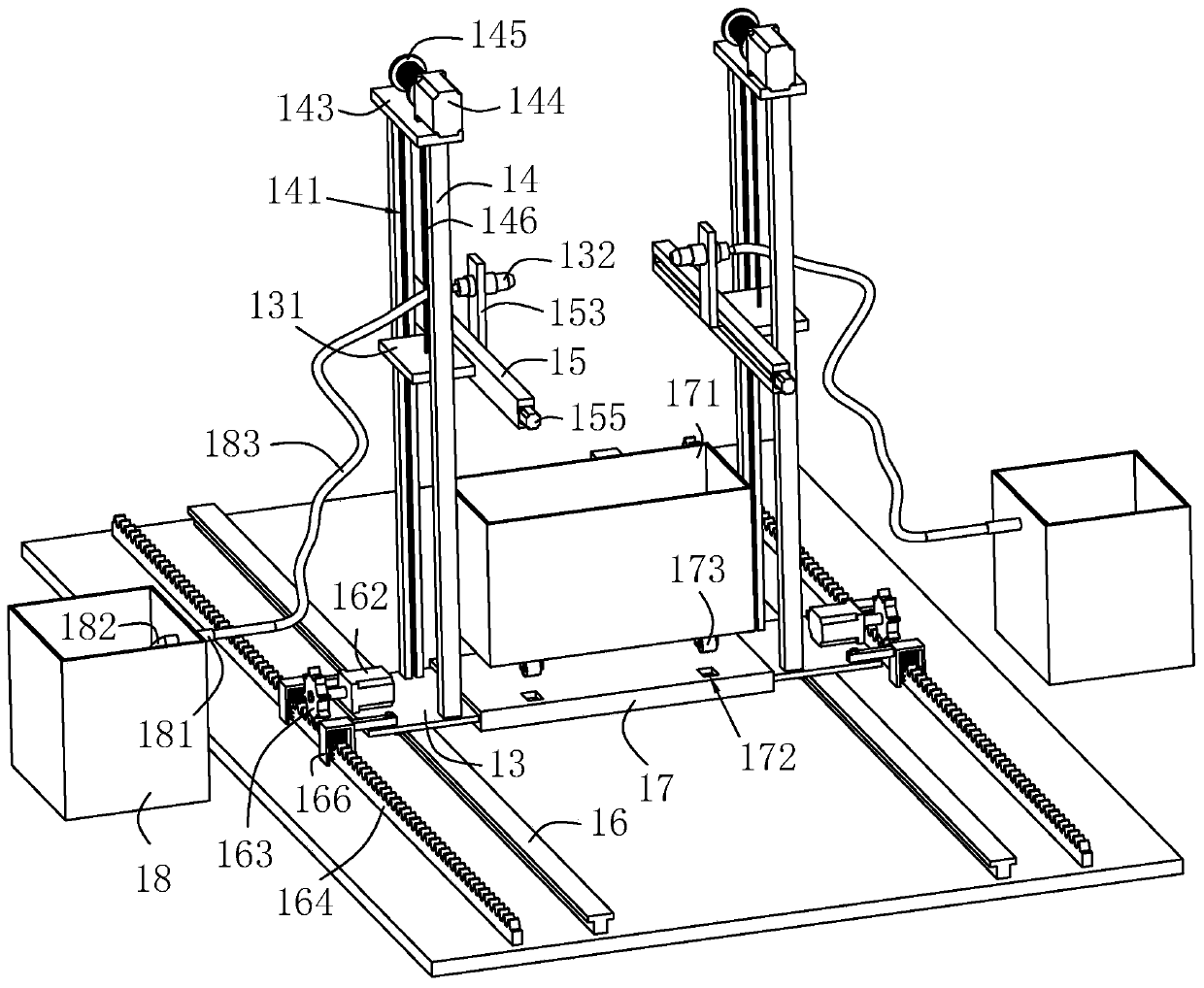

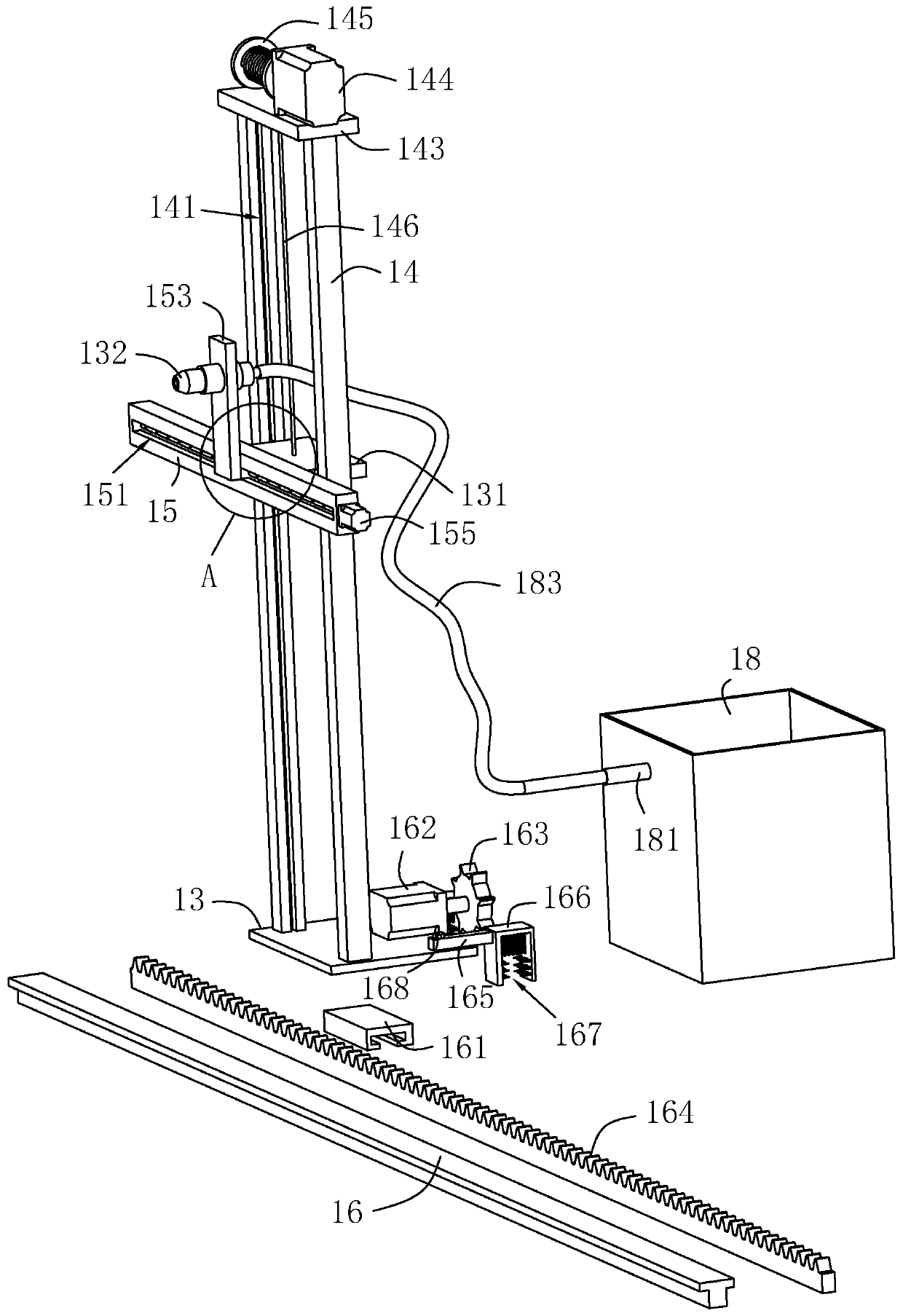

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

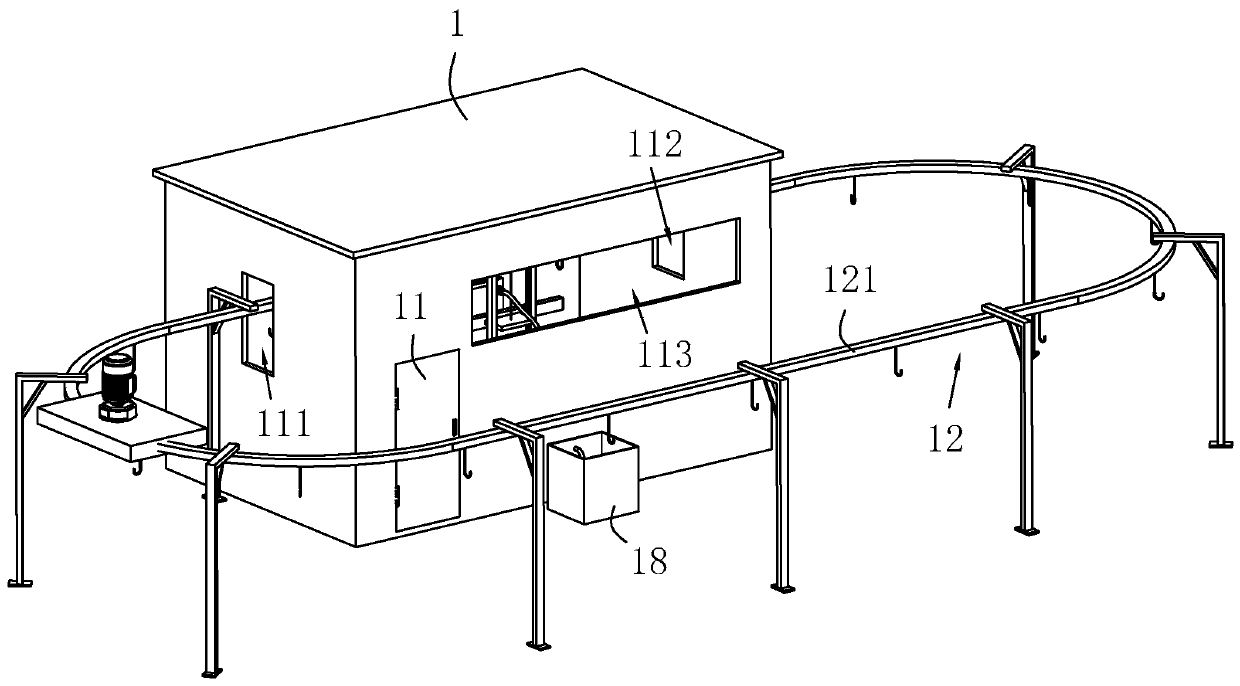

[0037] refer to figure 1 , is an automatic furniture spray booth disclosed by the present invention, comprising a room body 1 on which a door 11 for entering and exiting the room body 1 is hingedly arranged.

[0038] Such as figure 1 As shown, in order to facilitate the observation of the painting situation in the room body 1, an observation window 113 made of a transparent material is provided on the side wall of the room body 1 and at a position adjacent to the door 11; in this embodiment , set the transparent material to acrylic.

[0039] Such as figure 1 As shown, an inlet 111 and an outlet 112 are respectively provided on the side wall of the room body 1 and on the opposite surface of the room body 1; in order to transport the furniture into the room body 1, the automated furniture spray booth also includes a Enter along the entrance 111 and drive th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap