Household appliance production line locating mechanism

A positioning mechanism and production line technology, which is applied to positioning devices, grinding racks, and parts of grinding machine tools, can solve the problems of low processing efficiency and inconvenient operation of the clamping and positioning mechanism, and achieve convenient operation, convenient opening and cooperation Use the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

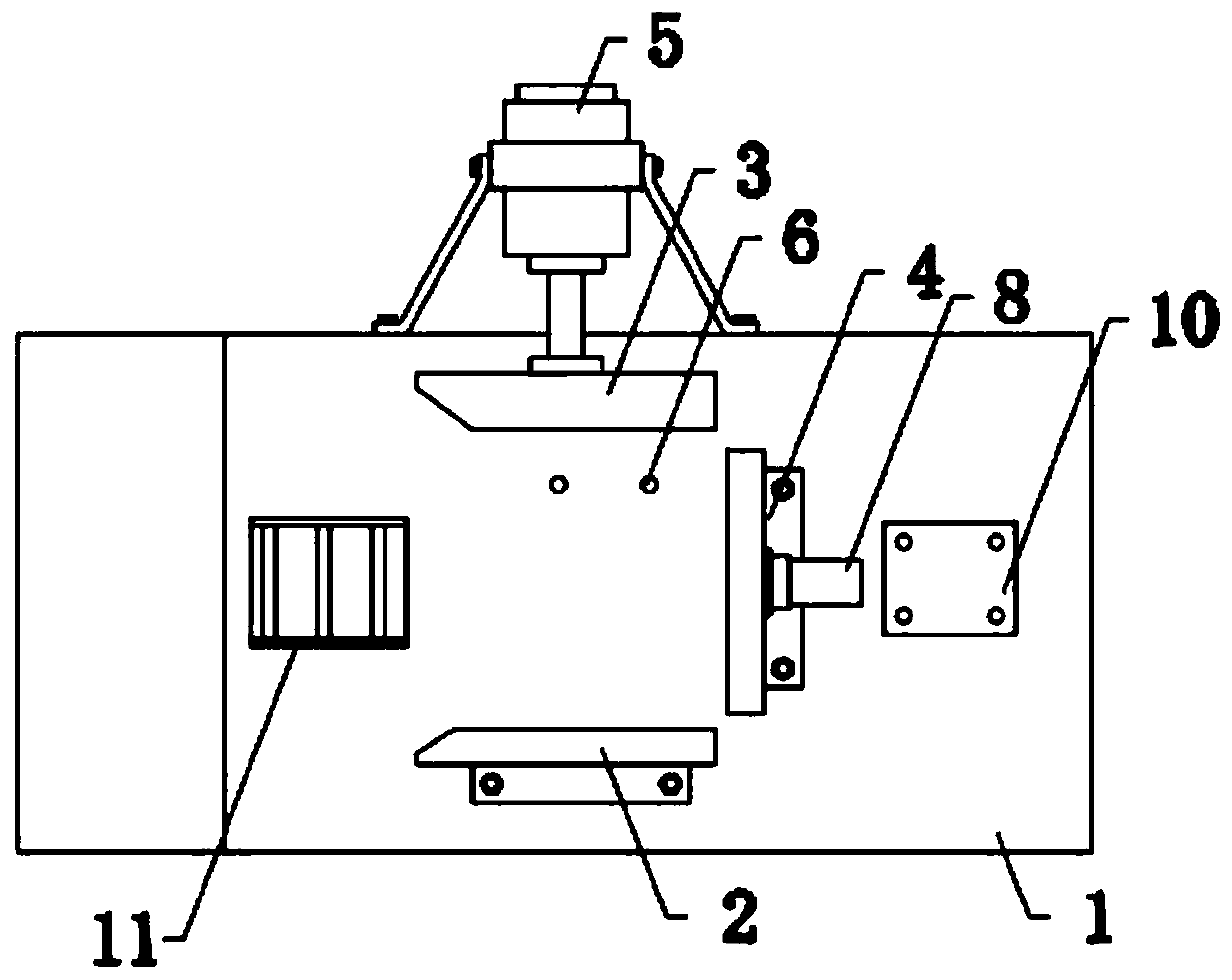

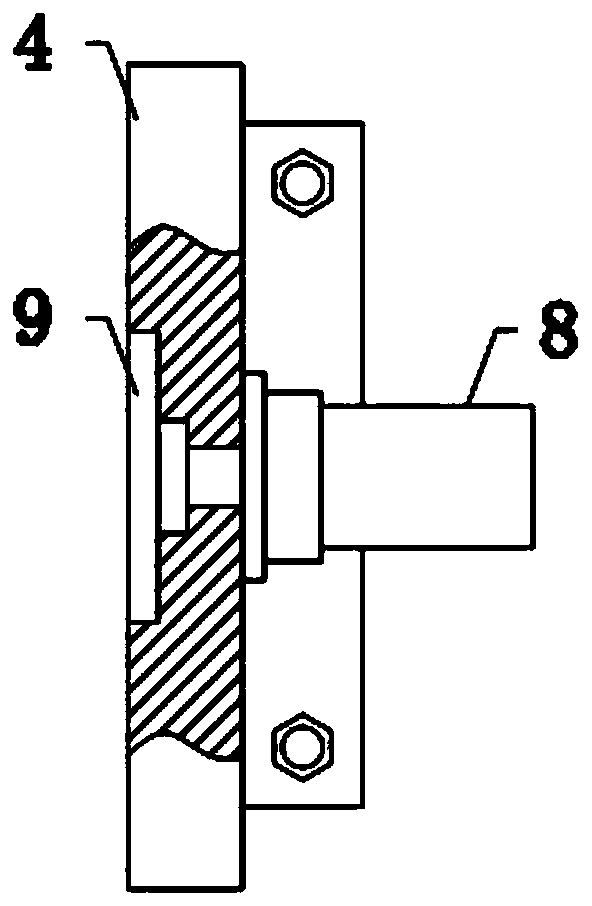

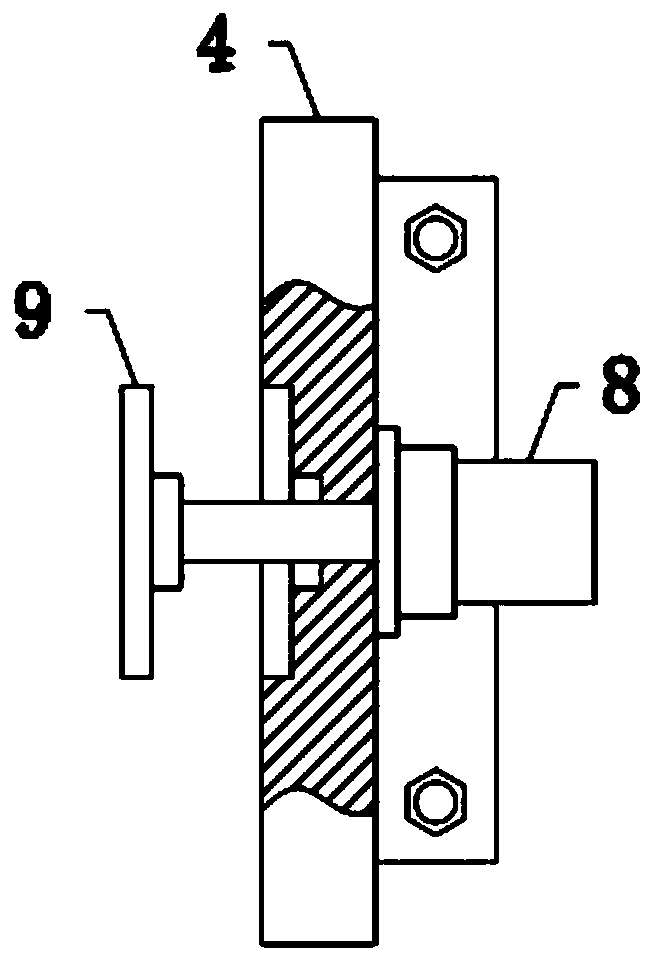

[0028] see Figure 1-5 , the present invention provides a technical solution: a positioning mechanism for a home appliance production line, including an operating table 1, on which a fixed splint 2, a movable splint 3 and a positioning plate 4 are arranged, and the position between the fixed splint 2 and the movable splint 3 Corresponding;

[0029] Both the fixed splint 2 and the positioning plate 4 are fixedly connected on the operating table 1, and the movable splint 3 can approach or move away from the fixed splint 2. When approaching, the object to be processed is clamped between the fixed splint 2 and the movable splint 3, realizing The role of clamping;

[0030] The positioning plate 4 is positioned on the right side between the fixed splint 2 and the movable splint 3, and the movable splint 3 is connected on the telescopic rod of the first drive cylinder 5, and the axis of the first drive cylinder 5 is perpendicular to the fixed splint 2 and the movable splint 3;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com