Transferring coding method for forward direction bottle lids

A bottle cap and positive technology, which is applied in the field of bottle cap coding, can solve the problems of reduced coding efficiency and unstable forward bottle cap transfer, so as to reduce labor costs, high bottle cap transportation efficiency, and improve transfer and transportation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

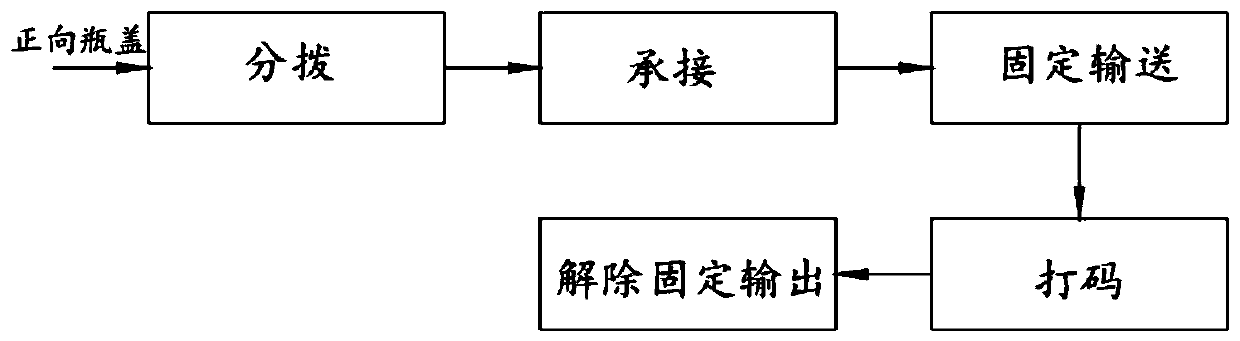

[0043] A transshipment coding method for forward bottle caps, comprising the following steps:

[0044] Step 1, distribution, the power unit 4 drives the distribution mechanism 22 to continuously push the positive bottle cap 8 from the central position of the turntable 21 to the blanking hole 211;

[0045] Step 2, accepting, after step 1, the positive bottle cap 8 falls from the drop hole 211 and is sleeved on the top of the thimble assembly 31;

[0046] Step 3, fixed transportation, after step 2, the conveying assembly 32 drives the thimble assembly 31 and the forward bottle cap 8 to transfer, the support assembly 61 at the top of the thimble assembly 31 cooperates with the switching assembly 62, the support Component 61 supports and fixes the positive bottle cap 8 from inside to outside;

[0047] Step 4, coding, after step 3, the thimble assembly 31 carries the fixed forward bottle cap 8 and transfers to the coding device 5 for coding;

[0048] Step 5, release the fixed out...

Embodiment 2

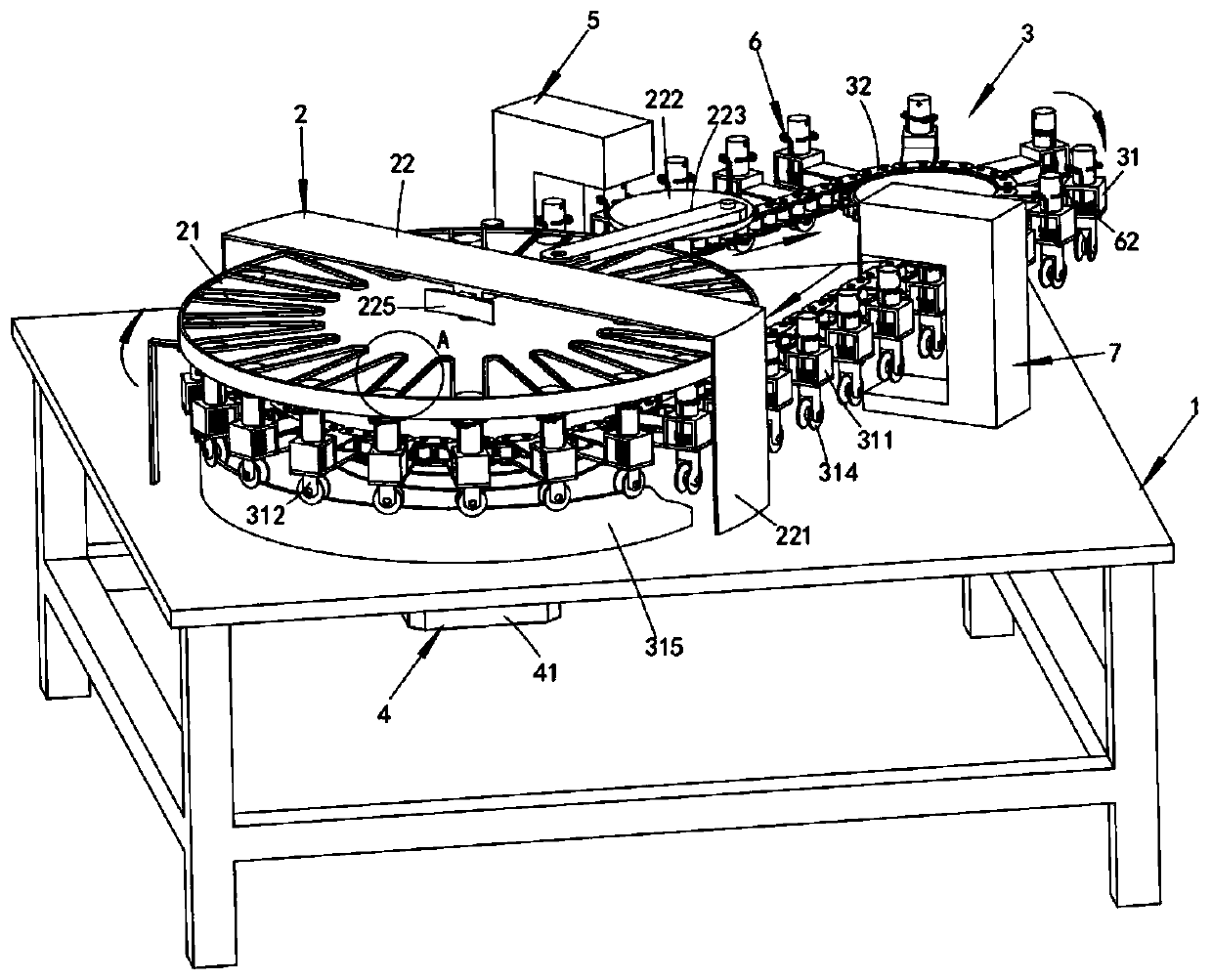

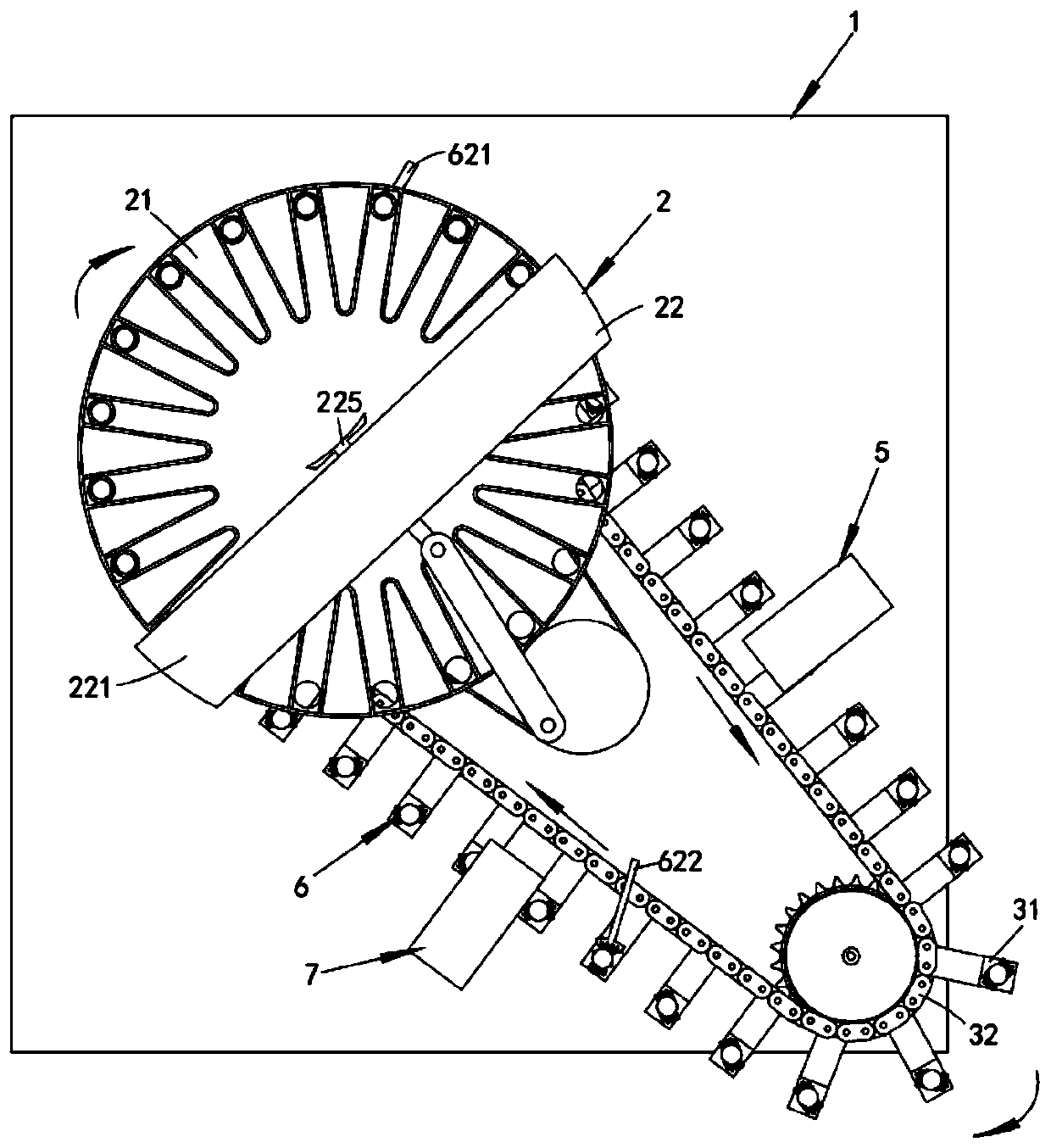

[0059] The present invention also provides a kind of forward coding equipment for bottle cap transportation, such as figure 2 and image 3 As shown, a kind of positive bottle cap transport coding equipment, including workbench 1, coding equipment 5 and output equipment 7, also includes:

[0060] The distribution device 2, the distribution device 2 includes a turntable 21 and a distribution mechanism 22, the turntable 21 is rotatably mounted on the workbench 1, and the reciprocating movement of the distribution mechanism 22 moves the center of the turntable 21 Push the bottle cap to the circular array in the blanking hole 211 at the edge of the turntable 21;

[0061] Conveying device 3, described conveying device 3 is positioned at the below of described distributing device 2, comprises thimble assembly 31 and conveying assembly 32, and several described thimble assemblies 31 are evenly distributed at the outer edge place of described conveying assembly 32, and described thim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com