Integrated drilling rod drilling tool slope movable sleeve system and matching method thereof

An integrated, sloped technology, applied in the direction of drilling tools, drill pipes, drill pipes, etc., can solve problems such as damage and delay in engineering task time, and achieve the effects of convenient assembly and disassembly, saving raw materials, and maintaining the structure and shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

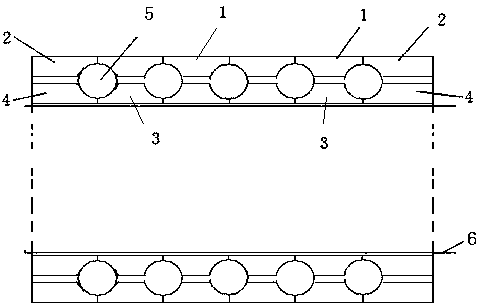

[0033] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

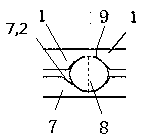

[0034] As shown in Figure 2, the integrated drill pipe drilling tool slope dynamic sleeve system, the slope dynamic sleeve system includes: a slope semicircular raceway dynamic sleeve body 7 with a tubular structure, and the inner wall of the slope semicircular raceway dynamic sleeve body 7 is set There is an inner diameter hole matched with the drill pipe 6; the axial outer wall of the inclined semicircular raceway moving sleeve body 7 is provided with an odd number of inclined semicircular raceways 7.1 for accommodating the rolling elements 5 with the same spacing.

[0035] The semicircular raceway of each semicircular raceway of the moving slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com