Transparent PET (Polyester) composite board

A composite plate and transparent technology, which is applied in the direction of synthetic resin layered products, decorative arts, special decorative structures, etc., can solve the problems of complicated process and heavy glass material, and achieve environmental protection, good weather resistance, simple manufacturing process, and reduced quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

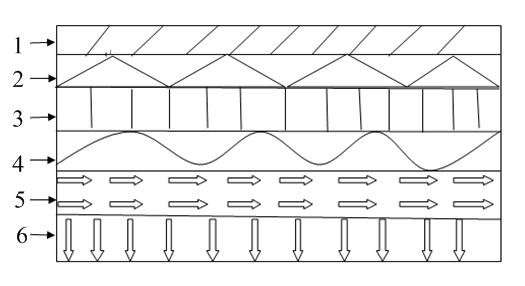

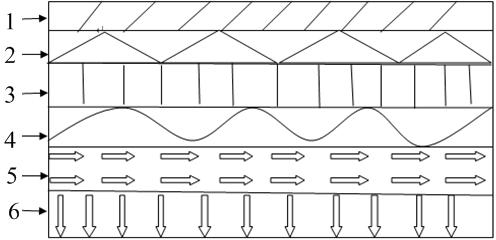

[0017] Such as figure 1 As shown, the transparent PET composite sheet, the front of the transparent PET film layer 2 is sprayed with UV coating 1, the thickness of the transparent PET film layer is 1-3mm, the back of the transparent PET film 2 is provided with a printing layer 3, and the printing layer 3 is sprayed on the back There is a primer layer 4, the back of the primer layer 4 is roll-coated with an adhesive layer 5, and a HIPS substrate layer 6 is bonded on the adhesive layer 5, and the thickness of the HIPS substrate layer 6 is 2-4 mm.

[0018] On the basis of the above structure, the UV coating 1 is covered with a PE protective film layer.

[0019] The transparent PET film layer 2 is sprayed with UV coating 1 on the front, and the bottom surface of the transparent PET is processed by continuous printing to form a printing layer 3. The bottom surface of the printing layer 3 is sprayed with a primer layer 4, and the bottom surface of the primer layer 4 is sprayed with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com